Method for treating wastewater of rubber vulcanization accelerator N-cyclohexyl-2-benzothiazole sulfonamide

A technology of benzothiazole sulfenamide and rubber vulcanization, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. operation and other problems to achieve the effect of solving the problem of high-salt wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

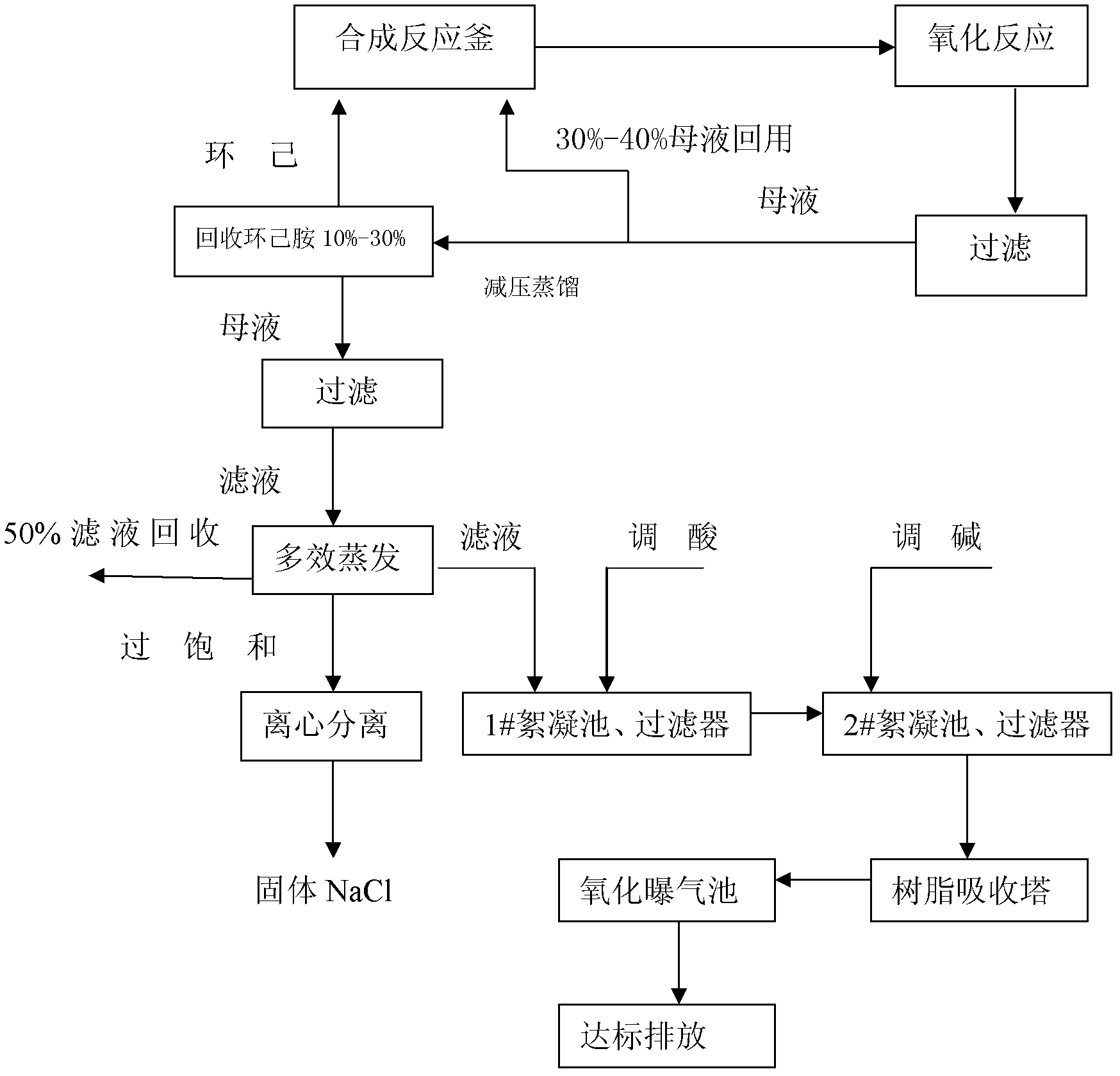

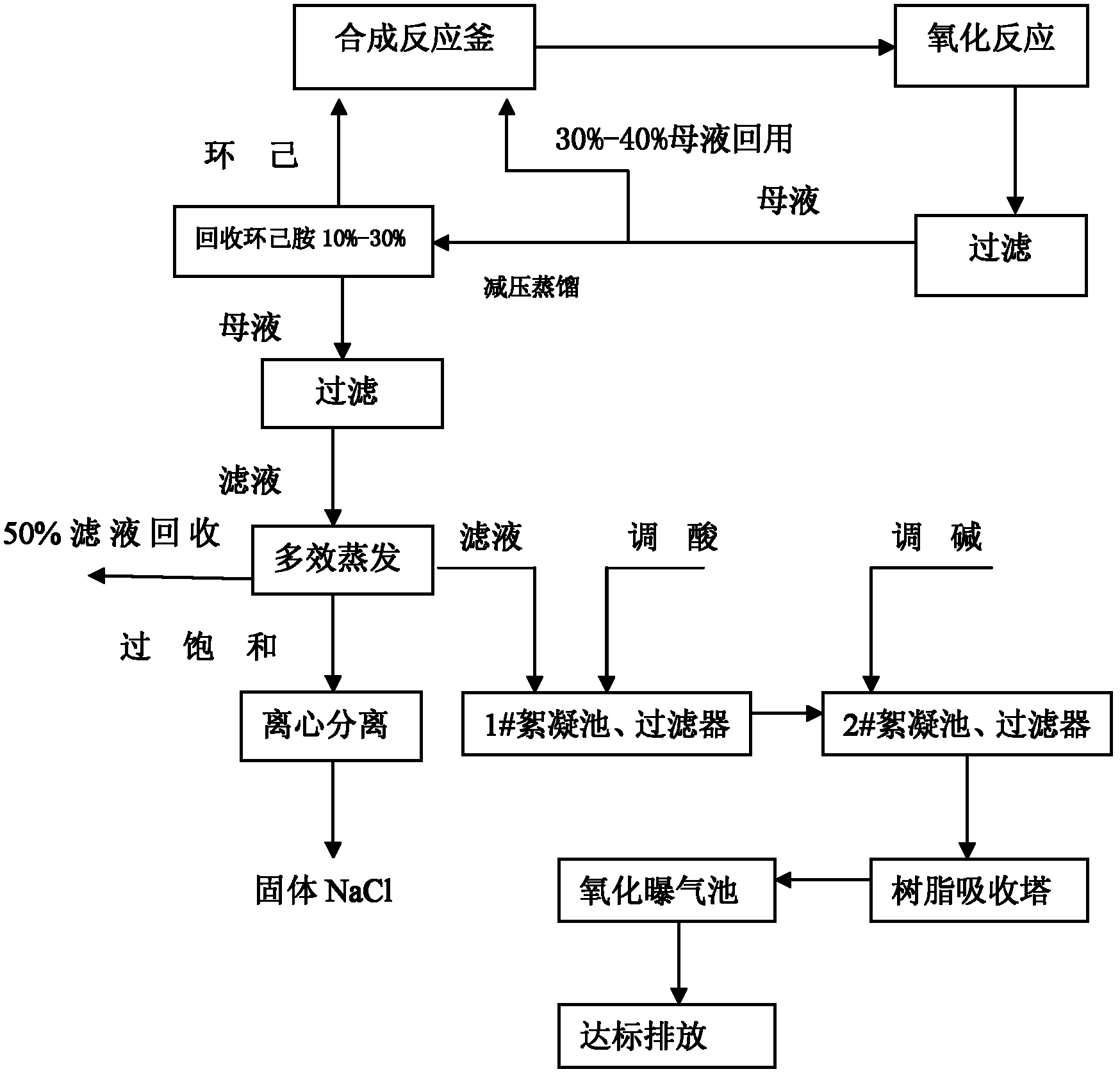

[0011] In the production process, the raw material M, cyclohexylamine, and sodium hypochlorite are mixed according to the ratio (process water 3.5-4.0m 3 , M1.2t, about 1kg of defoamer) put into the reactor for synthesis and oxidation reaction in turn, when the process reaches the synthesis of CZ slurry, CZ mother liquor (COD Cr About 1500mg / L), the mother liquor is the wastewater produced by the rubber vulcanization accelerator CZ. After filtering, the CZ mother liquor is separated from the material, the mother liquor settles for a period of time, pump out about 1 / 3 (30%-40%) of the mother liquor at the bottom, and send it to the CZ synthesis reactor to replace the process water for beating, and the remaining mother liquor is vacuum The temperature is -0.6~-0.8MPa, and the temperature is 70~80°C under reduced pressure distillation to recover cyclohexylamine, filter the mother liquor after distillation, introduce the filtrate into a multi-effect evaporator, concentrate to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com