Smelting method of corrosion-resistant soft magnetic alloy material

A technology of soft magnetic alloys and smelting methods, which is applied in the direction of magnetic materials, magnetic objects, and improvement of process efficiency. It can solve the problems of low production efficiency and low yield of corrosion-resistant soft magnetic alloy materials, and achieve good surface quality and improved One-time utilization rate and the effect of refining the organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0011] A method for smelting a corrosion-resistant soft magnetic alloy material, characterized by comprising the following steps:

[0012] (1) Preparation of electrode rod

[0013] The ingredients of the soft magnetic alloy material are (percentage by weight): C0.009%, Cr17.7%, Si1.25%, Mn0.5%, Ti0.45%, Al0.4%, Fe balance, smelted by intermediate frequency furnace , cast into a round rod with a diameter of Ф90mm, the surface is sanded and finished, and used as a self-fusing electrode rod for electroslag remelting;

[0014] (2) Electroslag remelting

[0015] The ratio of slag material for electroslag remelting is: CaF 2 :CaO:Al 2 o 3 =75:5:20 (weight ratio), the slag is heated to a molten state, poured into a crystallizer with a diameter of Ф160mm, and the self-fusing electrode rod prepared in step (1) is slowly dropped into the molten slag, After arcing, adjust the voltage to 40V and the melting current to 4000A. After the self-fusing electrode rod starts to melt, drive t...

example 2

[0018] A method for smelting a corrosion-resistant soft magnetic alloy material, characterized by comprising the following steps:

[0019] (1) Preparation of electrode rod

[0020] The ingredients of the soft magnetic alloy material are (percentage by weight): C0.008%, Cr17.7%, Si1.5%, Mn0.5%, Ti0.45%, Fe balance, melted in a vacuum induction furnace, and cast into a diameter It is a round rod of Ф170mm, after the surface is sanded and finished, it is used as a self-fusing electrode rod for electroslag remelting;

[0021] (2) Electroslag remelting

[0022] The ratio of slag material for electroslag remelting is: CaF 2 :CaO:Al 2 o 3 =72:3:25 (weight ratio), the slag is heated to a molten state, poured into a crystallizer with a diameter of Ф280mm, and the self-fusing electrode rod prepared in step (1) is slowly dropped into the molten slag, After arcing, adjust the voltage to 52V and the melting current to 6000A, turn on the ultrasonic generator, and drive the self-fusing ...

example 1 and example 2

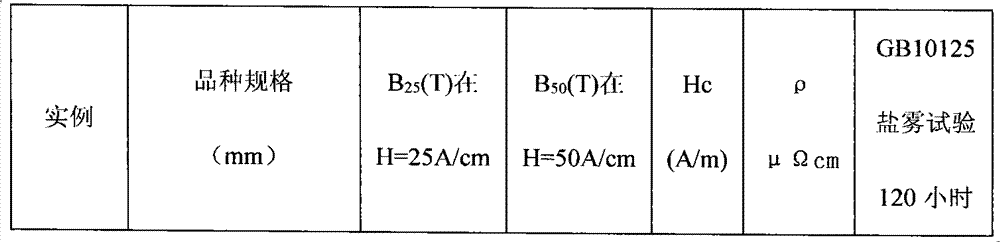

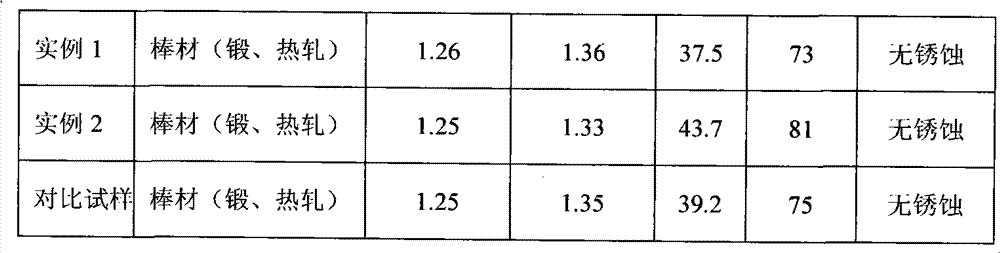

[0027] Table 2 Example 1 and Example 2 Magnetic properties and corrosion resistance of soft magnetic alloy materials

[0028]

[0029]

[0030] Remarks: The comparison sample is a soft magnetic alloy material smelted in an intermediate frequency furnace and not remelted by this method (the composition formula is the same as that of Example 1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com