Preparation method of styrene butadiene rubber

A technology of styrene-butadiene rubber and styrene, which is applied in the field of preparation of styrene-butadiene rubber, can solve problems such as low conversion rate and viscosity increase, and achieve the effects of reducing recycling energy consumption, increasing production capacity, and improving primary utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The specific steps of the above-mentioned preparation method provided by the present invention can adopt common steps in the art of polystyrene butadiene emulsion. In a preferred embodiment, the preparation method includes the following steps: mixing styrene, butadiene, soft water, emulsifier, reducing agent, molecular weight regulator, activator and electrolyte to obtain a mixed solution; adding an initiator for emulsion polymerization; when the conversion rate of the total monomers of the emulsion polymerization reaches 58-62%, adding an aqueous solution of potassium salt to the reaction system of the emulsion polymerization; and when the conversion rate of the total monomers of the emulsion polymerization reaches 68-72% , add a terminator to the emulsion polymerization reaction system to terminate the emulsion polymerization, and then obtain styrene-butadiene rubber. In this way, the initiator can be added to carry out polymerization after the reaction system is homo...

Embodiment 1

[0042] In the polymerization water bath, a 350ml polymerization bottle was used, and the polymerization bottle was replaced with vacuum and nitrogen. Add soft water, emulsifier, electrolyte, molecular weight regulator, reducing agent, activator, styrene, butadiene into the polymerization bottle, when the temperature of the polymerization bottle drops to 4.5°C, add hydrogen peroxide p-menthane to carry out polymerization experiment. When the conversion rate reaches 70%, a terminator is added, and stirring is continued for 0.5 h to terminate the polymerization reaction. Take a sample for viscosity testing.

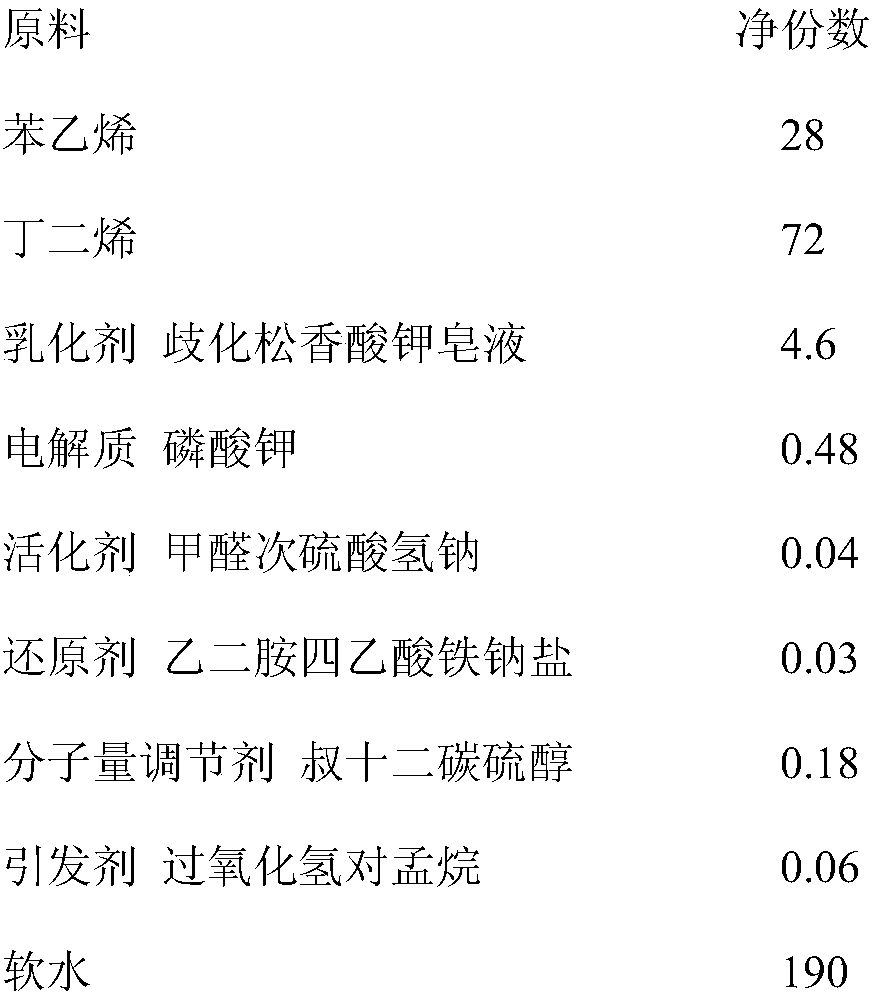

[0043] The above polymerization was carried out at 4.5°C based on the following recipe.

[0044]

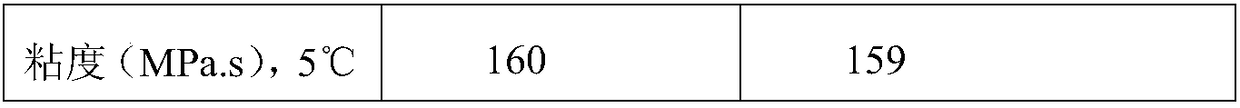

[0045] When the conversion rate reaches 60%, add mass concentration 8×10 -4 When potassium chloride aqueous solution is the total mass fraction of soft water 2%, the polymer emulsion viscosity is as follows:

[0046]

[0047]

[0048] Note: "When the conversion rat...

Embodiment 2

[0050] In the polymerization water bath, a 350ml polymerization bottle was used, and the polymerization bottle was replaced with vacuum and nitrogen. Add soft water, emulsifier, electrolyte, molecular weight regulator, reducing agent, activator, styrene, butadiene into the polymerization bottle, when the temperature of the polymerization bottle drops to 5.5°C, add hydrogen peroxide p-menthane to carry out polymerization experiment. When the conversion rate reaches 68%, a terminator is added, and stirring is continued for 1 h to terminate the polymerization reaction. Take a sample for viscosity testing.

[0051] The above polymerization was carried out at 5.5°C based on the following recipe.

[0052]

[0053] When the conversion rate reaches 58%, add mass concentration 1×10- 4 When potassium chloride aqueous solution is the total mass fraction of soft water 2%, the polymer emulsion viscosity is as follows:

[0054] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com