Automatic assembly method of recombined bamboo

A recombined bamboo and automatic technology, which is applied in the pretreatment of molding materials, household components, flat products, etc., can solve the problems of uneven paving of slabs, uneven density of plates, gaps in plates, etc., and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

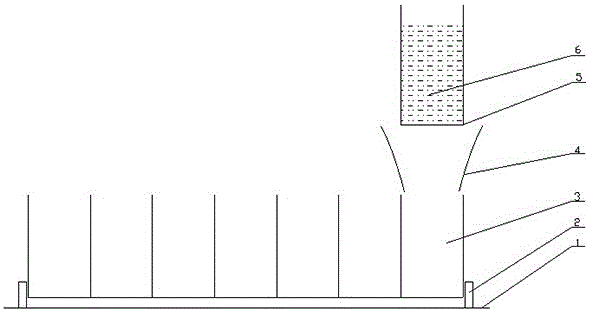

[0012] An automatic billet assembly method for recombined bamboo, including the following process steps: a) dipping and drying bamboo strips / bundles; b) weighing; c) automatically lifting and putting them into parallel cells on a backing plate; d) parallel cells The bamboo bundles in the grid slide down to the backing board.

[0013] The step a) dipping and drying the bamboo strips / bundles includes: drying the bamboo strips / bunches to a moisture content of 10-15%, impregnating them with phenolic glue, draining and drying at a low temperature of 50-80°C to a moisture content of 10-15%. 16%.

[0014] In the step b) weighing, the impregnated and dried rolled bamboo strips / bundles are weighed and quantified in a quantitative device.

[0015] The step c) is automatically lifted and placed into the parallel cells on the backing plate, including: the automatic removal device 5 moves the weighed bamboo bundle 6 from the weighing device to the designated top of the backing plate, corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com