Method for preparing p-benzoquinone by electrocatalytic oxidation of phenylamine

An electrocatalytic oxidation and aniline preparation technology, which is applied in the electrolytic process, electrolytic components, electrolytic organic production, etc., can solve the problems of low primary yield of aniline, insufficient primary utilization of pyrolusite powder, etc., and achieve the effect of improving the oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

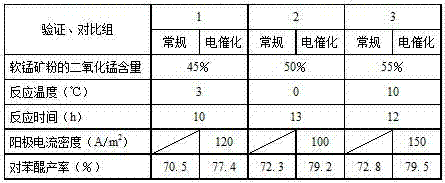

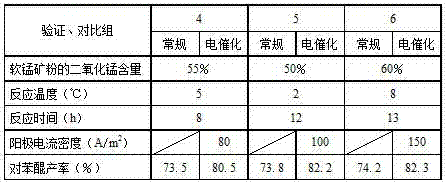

[0012] A method for preparing p-benzoquinone by electrocatalytic oxidation of aniline, the method may further comprise the steps:

[0013] (1) Put the pyrolusite powder and dilute sulfuric acid into the oxidation tank to prepare a solution; then add aniline dropwise to the solution so that the manganese dioxide contained in the pyrolusite powder can oxidize aniline; among them, the pyrolusite powder The manganese dioxide content is 45-60%;

[0014] (2) After the oxidation reaction is completed, the solution is distilled, crystallized, dehydrated and dried to obtain the product p-benzoquinone;

[0015] In the process of dropping aniline in step (1), the present invention performs electrocatalytic oxidation, and the anode current density of the electrocatalytic oxidation is 80-150A / m 2 , the temperature is 0-10°C, and the time is 8-13 hours; the particle size of pyrolusite powder is not greater than 0.15mm (that is, passing through a 100-mesh Taylor standard sieve); the mass pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com