Polycrystalline silicon production process and production system used for same

A production process, polysilicon technology, applied in the direction of silicon compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of increased metal impurity precipitation, damage, high temperature in the center of silicon rods, etc., to achieve the effect of increasing supersaturation and preventing cauliflower material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

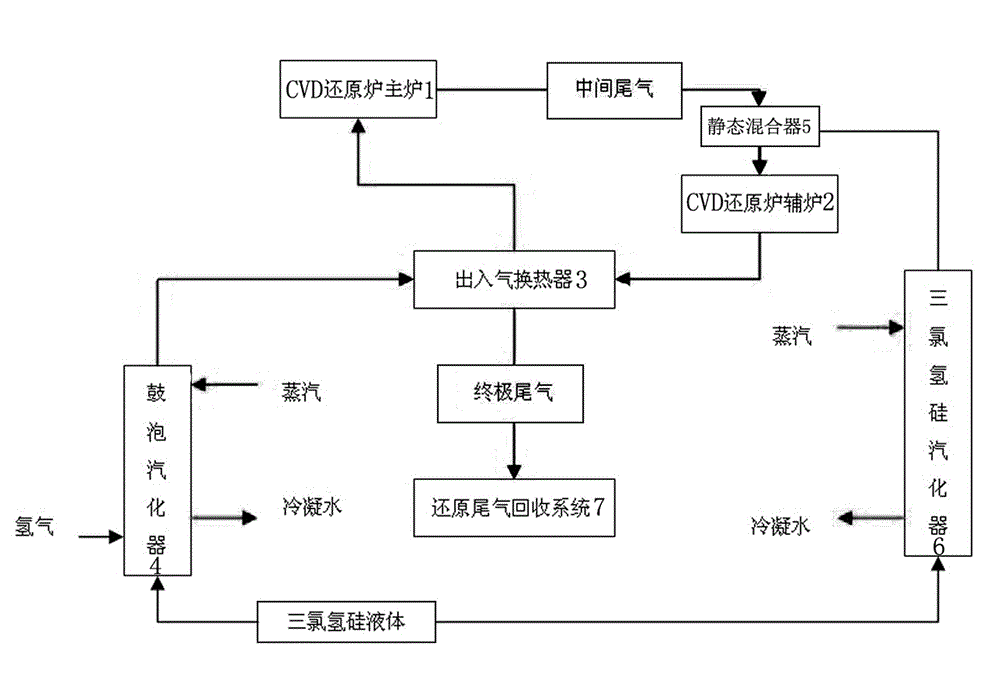

[0035] Such as figure 1 As shown, refined trichlorosilane and hydrogen are mixed in the bubbling vaporizer 4, and by controlling the pressure and temperature of the bubbling vaporizer 4, hydrogen and refined trichlorosilane are transported to the inlet and outlet gas at a molar ratio of 3:1. heat exchanger 3.

[0036] The mixed gas feed entering the inlet and outlet gas heat exchanger 3 is heat-exchanged with the high-temperature final tail gas from the auxiliary furnace 2 of the CVD reduction furnace, which not only increases the feed temperature but also reduces the final tail gas temperature.

[0037] After the mixed gas feed is heated by the final exhaust gas from the auxiliary furnace 2 of the CVD reduction furnace, it continues to enter the main furnace 1 of the CVD reduction furnace, and reacts on the surface of the silicon core at 1150 °C in the main furnace 1 of the CVD reduction furnace to form polysilicon.

[0038] The by-product of the main furnace 1 of the CVD red...

Embodiment 2

[0042] Such as figure 1 As shown, refined trichlorosilane and hydrogen are mixed in the bubbling vaporizer 4, and by controlling the pressure and temperature of the bubbling vaporizer 4, hydrogen and refined trichlorosilane are delivered to the inlet and outlet gas at a molar ratio of 4:1. heat exchanger 3.

[0043] The mixed gas feed entering the inlet and outlet gas heat exchanger 3 is heat-exchanged with the high-temperature final tail gas from the auxiliary furnace 2 of the CVD reduction furnace, which not only increases the feed temperature but also reduces the final tail gas temperature.

[0044] After the mixed gas feed is heated by the final tail gas from the auxiliary furnace 2 of the CVD reduction furnace, it continues to enter the main furnace 1 of the CVD reduction furnace, and reacts on the surface of the silicon core at 1150°C in the main furnace to form polysilicon.

[0045] The by-product of the main furnace 1 of the CVD reduction furnace is used as the inter...

Embodiment 3

[0049] Such as figure 1 As shown, refined trichlorosilane and hydrogen are mixed in the bubbling vaporizer 4, and by controlling the pressure and temperature of the bubbling vaporizer 4, hydrogen and refined trichlorosilane are transported to the inlet and outlet gas at a molar ratio of 3.5:1. heat exchanger 3.

[0050] The mixed gas feed entering the inlet and outlet gas heat exchanger 3 is heat-exchanged with the high-temperature final tail gas from the auxiliary furnace 2 of the CVD reduction furnace, which not only increases the feed temperature but also reduces the final tail gas temperature.

[0051] After the mixed gas feed is heated by the final tail gas from the auxiliary furnace 2 of the CVD reduction furnace, it continues to enter the main furnace 1 of the CVD reduction furnace, and reacts on the surface of the silicon core at 1150°C in the main furnace to form polysilicon.

[0052] The by-product of the main furnace 1 of the CVD reduction furnace is used as the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com