Novel columnar vertical fluorination reactor

A reactor and main reactor technology, applied in the field of uranium conversion, can solve the problems of low utilization rate of primary fluorine gas, high corrosion rate of furnace body, high local corrosion rate, etc. The effect of loosening the requirements of seam and process control conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

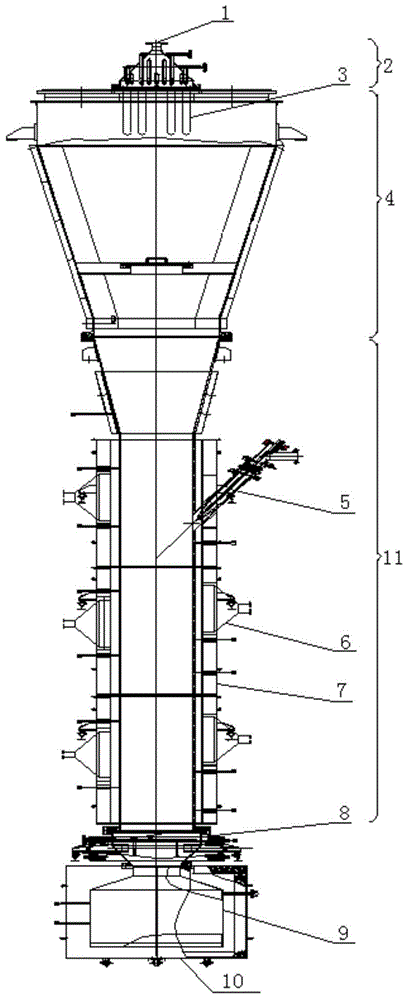

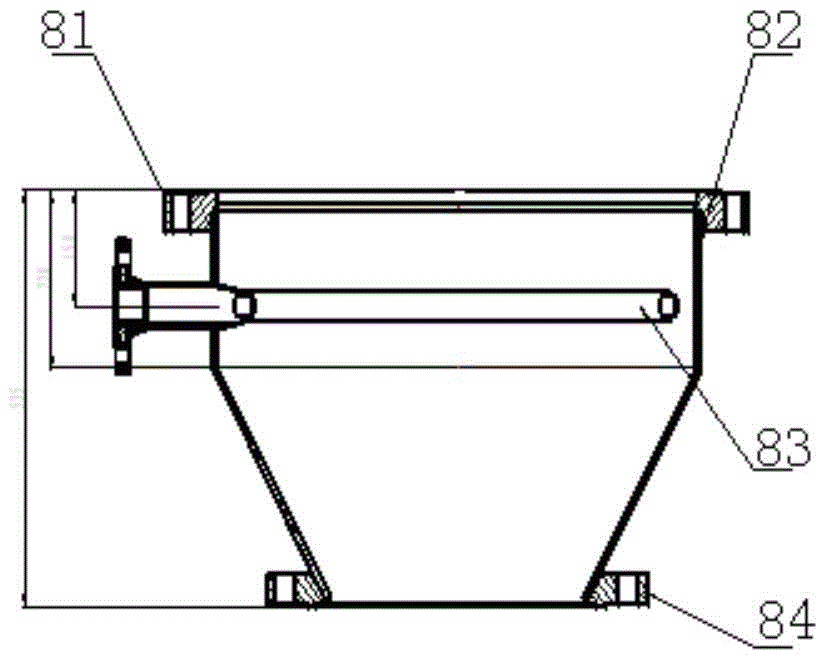

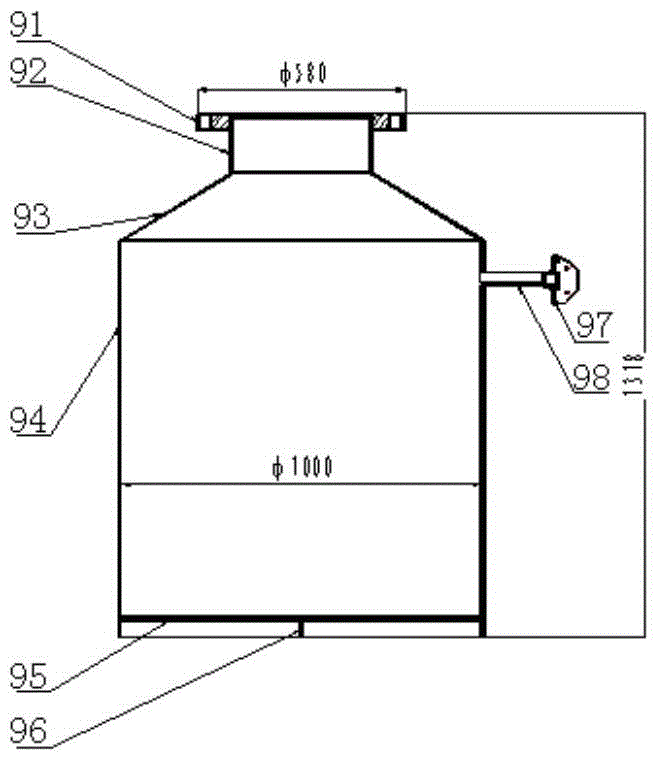

[0023] The technical scheme of this embodiment is a novel columnar vertical fluorination reactor, such as figure 1 As shown, including furnace gas outlet upper flange 1, dust removal device 2, filter pipe 3, upper expansion section 4, inclined feeding pipe 5, exhaust port 6, heating device 7, gas chamber 8, slag tank 9, lead layer The shielding sleeve 10 and the main reactor 11; wherein, the main reactor 11 is the main structure, the upper section is in the shape of an inverted truncated cone, the middle and lower section is cylindrical, and the cylindrical part of the main reactor 11 is set in three sections, namely the upper section, the middle section, Lower section; the upper end surface of the main reactor 11 is flanged to fix the upper expansion section 4 used for the gas-solid countercurrent contact reaction, the upper part of the upper expansion secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com