Method for recovering polyolefin tail gas hydrocarbons through full-temperature-range absorption extraction

A polyolefin, full temperature range technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as low purity and yield of olefin components, long process, difficult desorption, etc., to achieve desorption solution The process is extremely difficult to choose, the process is compact and energy-saving, and the effect of solving the difficulty of desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

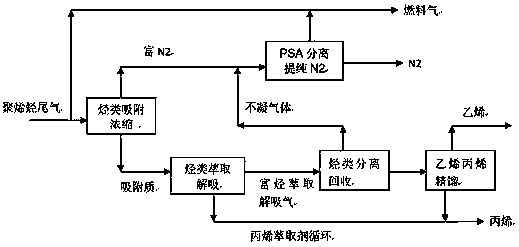

[0040] Such as figure 1 Shown, a kind of method for the hydrocarbons of full-temperature adsorption extraction recovery polyolefin tail gas, comprises following procedure:

[0041] (1) Hydrocarbon adsorption and concentration process, the composition of polyolefin mixed tail gas as feed gas is, among them, C2+ hydrocarbon components include 25.5% ethylene content (volume ratio, the same below), 17.5% propylene content, and N2 content 48.2%, H2 content 8.7%, and a small amount of C4 / C5 (C4+) components, the feed gas temperature is 20~40°C, the pressure is 3.0~4.0MPa, and it directly enters the adsorption tower composed of 2 parallel connections. One adsorption tower performs hydrocarbon adsorption and concentration, and the adsorption temperature and adsorption pressure are the same as the feed temperature and pressure of polyolefin mixed tail gas; the other adsorption tower is in the hydrocarbon extraction and desorption process, that is, the adsorbent regeneration state. The...

Embodiment 2

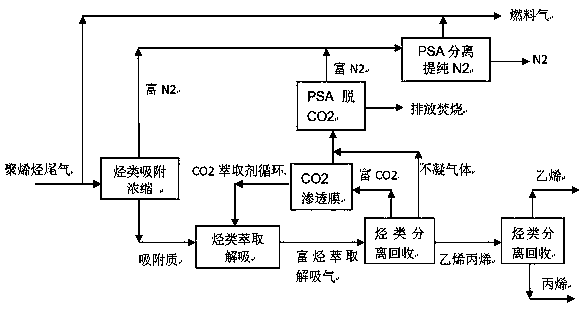

[0051] On the basis of a method for recovering polyolefin tail gas hydrocarbons described in Example 1 using full-temperature adsorption extraction to further optimize, the polyolefin mixed tail gas, that is, the H2 content in the feed gas component drops to 1.7%, C4, The C5 component increases to 7.1%, and the remaining components, temperature, pressure, etc. remain unchanged. Due to the increase in the content of C4+ hydrocarbon components in the feed gas, it is necessary to carry out the condensation cooling step in the hydrocarbon separation and recovery process step by step. First, while maintaining the pressure and temperature constant, discharge most of the non-condensable gas N2; secondly, The primary condensation cooling temperature is 15~20°C. First, the C4+ hydrocarbon components are condensed and cooled to achieve separation, and sent out to the boundary area for use as by-products. At the same time, the remaining non-condensable gas N2, etc. is continuously dischar...

Embodiment 3

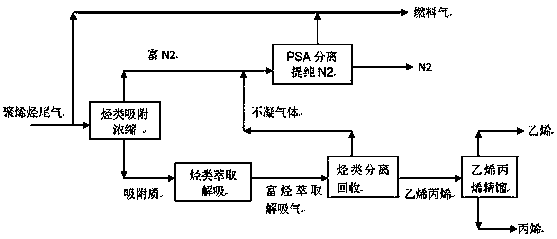

[0053] On the basis of a method described in Example 1 that uses full-temperature adsorption extraction to recover polyolefin tail gas hydrocarbons, it is further optimized. The composition of the raw material gas remains unchanged, and the amount of raw material gas reaches 20,000 to 30,000 standard cubic meters per hour. , the temperature is 60~70°C, the pressure is 3.5~4.5MPa, directly enters the hydrocarbon adsorption and concentration process, and the adsorption is carried out in a system consisting of an operating temperature of 60~70°C, an adsorption pressure of 3.5~4.5MPa, and 4 adsorption towers. , 4 adsorption towers are connected in parallel 2-2 respectively, 2 adsorption towers absorb, and the other 2 adsorption towers extract and desorb. In this embodiment, the temperature, pressure and processing capacity of the feed gas have increased, therefore, the further increase in the adsorption operation temperature, pressure and the number of adsorption towers in the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com