A purification method for ultra-pure ammonia full-temperature adsorption extraction deep dehydration and impurity removal

A deep dehydration and ultra-pure ammonia technology, applied in chemical instruments and methods, ammonia compounds, ammonia preparation/separation, etc., can solve the problem of increased operating load and separation difficulty, shortened service life of adsorbent, uneconomical and reasonable energy efficiency ratio, etc. problems, to achieve the effect of large selective dissolving capacity, expanding the difference in adsorption force, and good balance and matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

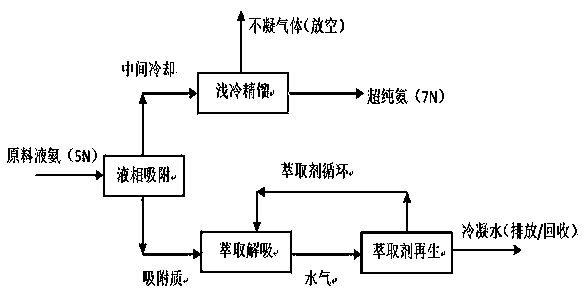

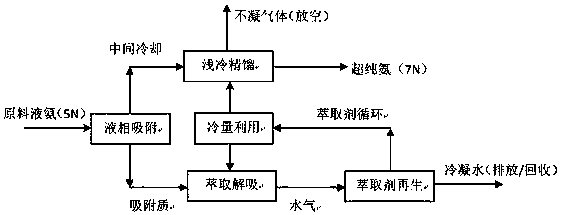

[0038] like figure 1 As shown, a purification method for full-temperature adsorption extraction and deep dehydration and impurity removal of ultra-pure ammonia includes the following steps:

[0039] (1) Liquid phase adsorption process, liquid ammonia with a purity of 99.999% (v / v, 5N grade, the same below) is used as the raw material liquid, at a temperature of -10~10°C, 1.0~2.0MPa, enters a The adsorption tower performs liquid-phase adsorption at an adsorption temperature of -10~10°C and an adsorption pressure of 1.0~2.0 MPa. A small amount of water is used as an adsorbate, which is absorbed by the adsorbent loaded in the adsorption tower. After the adsorption is saturated, enter the next step process, extraction and desorption process; ammonia and a small amount of low-boiling impurity components are not adsorbed and flow out from the bottom of the adsorption tower to obtain dehydrated liquid ammonia (hereinafter referred to as "intermediate liquid"), in which the moisture c...

Embodiment 2

[0050] On the basis of the purification method described in Example 1, the purification method of full-temperature adsorption, extraction, deep dehydration and impurity removal of ultra-pure ammonia is further optimized, and the liquid ammonia with a purity of 99.999% is used as the raw material liquid at a temperature of 20-40 ° C. , 3.0~4.0MPa, enter an adsorption tower from the top of the tower, and perform liquid phase adsorption at an adsorption temperature of 20~40°C and an adsorption pressure of 3.0~4.0MPa. After the adsorption is saturated, enter the next step, the extraction and desorption process; ammonia and traces of low-boiling impurity components are not adsorbed, but flow out from the bottom of the adsorption tower to obtain dehydrated liquid ammonia, in which the moisture content is less than 1ppbv; one adsorption tower absorbs When it is finished and enters the extraction and desorption process, another adsorption tower enters the liquid phase adsorption proces...

Embodiment 3

[0052] On the basis of the purification method of a kind of ultra-pure ammonia described in Example 1, the purification method of full-temperature adsorption, extraction, deep dehydration and impurity removal is further optimized. The liquid ammonia with a purity of 99.999% is used as the raw material liquid at a temperature of -40~- 30°C, the pressure is normal pressure, enters an adsorption tower from the top of the tower, and performs liquid phase adsorption at the adsorption temperature -40~-30°C and the adsorption pressure is normal pressure. The adsorbent is adsorbed, and after the adsorption is saturated, it enters the next step, the extraction and desorption process; ammonia and a small amount of low-boiling impurity components are not adsorbed, but flow out from the bottom of the adsorption tower to obtain dehydrated liquid ammonia (intermediate liquid), in which the moisture content is less than 1ppbv; when one adsorption tower finishes the adsorption and enters the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com