A method for adsorption, extraction, separation and purification of high alkynes in crude acetylene gas

A technology of high alkyne and acetylene gas is applied in the field of adsorption, extraction, separation and purification of high alkyne in crude acetylene gas, which can solve the problems of waste of acetylene, explosion, and difficulty in realizing steps, and achieves the effect of avoiding potential safety hazards and solving difficulty in desorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

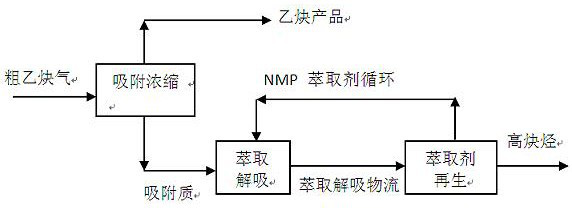

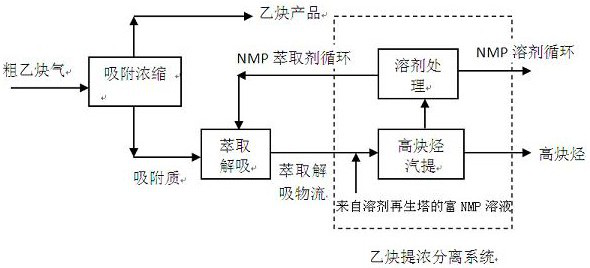

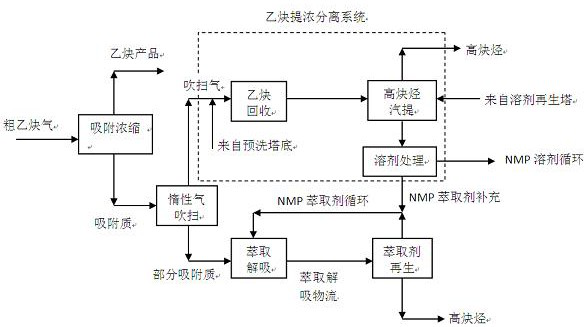

[0037] Such as figure 1 As shown, a method for adsorption, extraction, separation and purification of high alkynes in crude acetylene gas comprises the following steps:

[0038] (1) Adsorption and concentration process, the crude acetylene gas containing 40-100ppm of high alkyne, under normal pressure, the temperature is 50-70 ℃, enters an adsorption tower from the bottom of the adsorption tower, and the adsorption temperature is 50-70 ℃ and the adsorption pressure Adsorption is carried out under normal pressure. Higher alkynes and their trace impurities (hereinafter collectively referred to as "higher alkynes") are used as adsorbates and are adsorbed by the adsorbent packed in the adsorption tower. After the adsorption is saturated, enter the next step, extraction and desorption Process: Acetylene is not adsorbed and flows out from the top of the adsorption tower to obtain an acetylene product with an acetylene content greater than 99.8~99.9% and a high alkyne content of less...

Embodiment 2

[0046] On the basis of the adsorption, extraction, separation and purification method of high alkyne in a kind of crude acetylene gas described in Example 1, further optimization, the crude acetylene gas feed temperature in the adsorption concentration process is 10 ~ 30 ° C, normal pressure, adsorption The temperature is normal temperature, the adsorption pressure is negative pressure, and the crude acetylene gas enters from the top of the evacuated adsorption tower. In the adsorption concentration process, the high alkyne component as the adsorbate is adsorbed by the adsorbent, and acetylene is not adsorbed. Due to the low feed temperature, if the adsorption is carried out at normal pressure and low temperature, acetylene may also undergo co-adsorption, which will lead to a decrease in the yield of acetylene, a further increase in the regeneration load of the adsorbent, and will also lead to subsequent consumption of the extraction agent (NMP). increase and the increase in e...

Embodiment 3

[0048] On the basis of the adsorption, extraction, separation and purification method of high alkyne in a kind of crude acetylene gas described in Example 1, it is further optimized. The crude acetylene gas in the adsorption and concentration process is the acetylene enrichment from the production process of methane partial oxidation method. In the acetylene recovery tower in the separation system, the concentration of acetylene is 96%, and the concentration of high alkynes is 4%. Temperature and pressure. In the extraction and desorption process, the NMP extraction agent is used for extraction and desorption at normal temperature and pressure, and the amount of extraction agent used is correspondingly increased by 20-50%. In the extraction agent regeneration process, negative pressure and 100~120°C flash or steam stripping methods are used to completely regenerate the extractant and release high alkynes completely. The purity of the acetylene product is above 99.8%, the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com