A full-temperature adsorption-extraction separation method for recovering h2 and c2+ from refinery dry gas

A refinery dry gas, full temperature range technology, applied in the direction of extraction purification/separation, adsorption purification/separation, hydrocarbon purification/separation, etc., can solve the problem that the inherent bottleneck of separation technology cannot be completely solved, cannot be solved, and the process is long , to achieve the effect of easy adsorption-difficult desorption, reduced energy consumption, and large solvency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

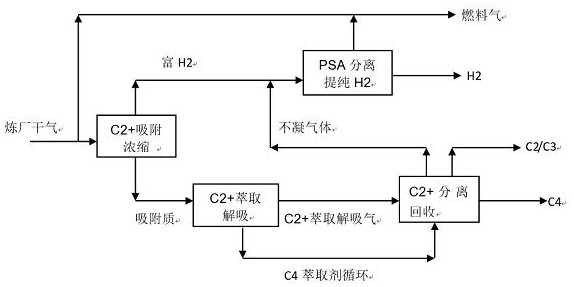

[0043] Such as figure 1 As shown, a full-temperature adsorption extraction separation method for recovery of H2 and C2+ from refinery dry gas includes the following procedures:

[0044] (1) C2+ adsorption concentration process, temperature is 50~60℃, pressure is 3.0~4.0MPa, H2 content is 35% (V / V, the same below), C2+ content is 16%, methane is 38%, other inert components The 11% refinery dry gas directly enters the C2+ adsorption and concentration system through the intake pipe without cooling or pressurization, and adopts a 2-tower parallel process at an operating temperature of 50~60°C and an operating pressure of 3.0~4.0MPa. Adsorption, one adsorption tower performs medium-temperature and medium-pressure adsorption, the other adsorption tower performs isothermal and isobaric C2+ extraction and desorption, and the two adsorption towers alternately perform isothermal and isobaric adsorption-extraction-desorption cycle operations to ensure continuous dry gas in the refinery ...

Embodiment 2

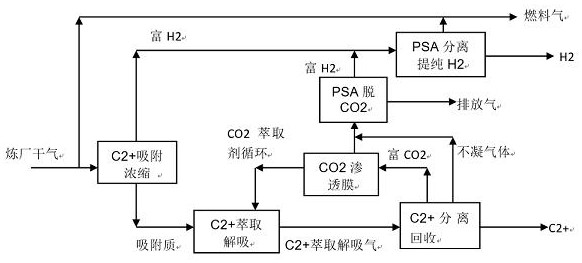

[0054] On the basis of the full-temperature adsorption-extraction separation method for recovering H2 and C2+ from refinery dry gas described in Example 1, it is further optimized. Before entering the C2+ adsorption and concentration process, it is necessary to add a purifying pretreatment device for acid gas removal . In this example, the refinery dry gas contains 1-5% CO2, 1-2% H2O and 0.1% H2S, and the C2+ components, temperature and pressure in the feed gas remain unchanged. Before the raw material gas enters the C2+ adsorption and concentration process, add a set of desulfurization and decarbonization device of alcohol amine absorption method and temperature swing adsorption (TSA) dehydration and drying device, so that CO2 in the raw gas of refinery dry gas≤0.01~0.1%, H2S≤ 10ppm, H2O≤0.01%. Refinery dry gas after removing acid gas and drying and dehydration, as raw material gas, directly enters the C2+ adsorption and concentration process to separate and extract H2 and C...

Embodiment 3

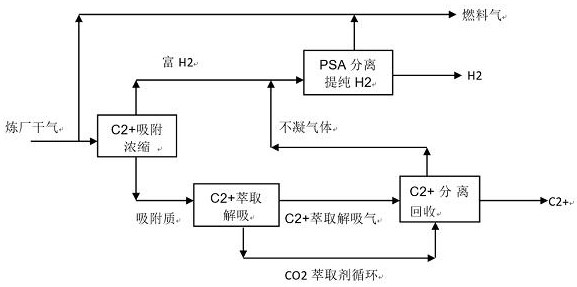

[0056]On the basis of a full-temperature adsorption extraction separation method for recovering H2 and C2+ from refinery dry gas described in Example 1, further optimization is carried out. The composition of the raw material gas remains unchanged, the temperature is 90-120 ° C, and the pressure is 0.5 At ~1.5MPa, it directly enters the C2+ adsorption and concentration process, and the adsorption is carried out in a system consisting of operating temperature 90~120°C, adsorption pressure 0.5~1.5MPa, and 2 adsorption towers, one of which absorbs and the other extracts For desorption, the two adsorption towers are alternately cycled to ensure continuous operation. In the C2+ extraction and desorption process, the critical C4 mixed alkanes at 90~120°C and 4.0~5.0MPa are used as the extraction agent to perform critical extraction and dissolution of the adsorbate C2+ adsorbed on the adsorbent, so that the C2+ in the extraction and desorption gas is mixed. The concentration of compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com