A separation and purification method for energy-saving dehydration and impurity removal of ethylene glycol aqueous solution

An ethylene glycol, aqueous solution technology, applied in the separation/purification of hydroxyl compounds, chemical instruments and methods, organic chemistry, etc. The effect of saving energy consumption, improving safety and improving input-output ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

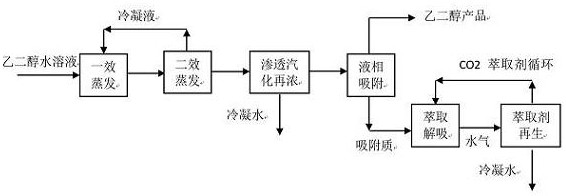

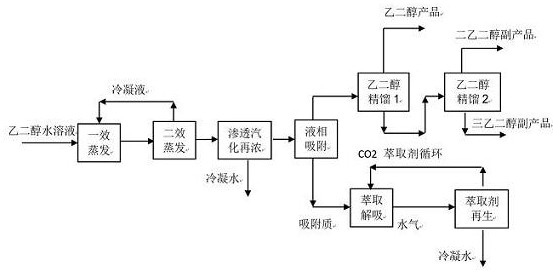

[0038] like figure 1 and figure 2 Shown, a kind of separation and purification method of ethylene glycol aqueous solution dehydration impurity removal, comprises following operation:

[0039] (1) Multi-effect evaporation and concentration process, the ethylene glycol aqueous solution with a concentration of about 25% (mass ratio, the same below) from the ethylene oxide hydration reactor, the temperature is 100°C, and enters the co-current second effect after pressure relief The first-effect evaporator of the evaporation system, evaporates and concentrates to 40%, and then sends it to the second-effect evaporator, evaporates and concentrates to about 60%, and realizes initial concentration. Among them, the condensate of the second-effect secondary steam is introduced at the top of the second-effect evaporator as the reflux liquid, so that it is in countercurrent contact with the rising secondary steam in the evaporator, and the ethylene glycol component in the steam is recove...

Embodiment 2

[0050] On the basis of the separation and purification method for energy-saving dehydration and impurity removal of a kind of ethylene glycol aqueous solution described in Example 1, it is further optimized. In the pervaporation re-concentration process, a vacuum pump is used to obtain a certain vacuum on the permeation side of the pervaporation membrane. The method maintains the partial pressure difference between water and trace impurity components on both sides of the pervaporation membrane, allowing water and trace impurity components to pass through continuously, while the non-permeable ethylene glycol components are further concentrated to 88~90 %, as the feed liquid of the next process-liquid phase adsorption process, it is passed into the liquid phase adsorption tower for liquid phase adsorption, and the ethylene glycol product with a purity of 99.9~99.99% or more is obtained from the bottom of the tower. This can reduce the load of the liquid phase adsorption process. ...

Embodiment 3

[0052] On the basis of the separation and purification method of dehydration and impurity removal of a kind of ethylene glycol aqueous solution described in Example 1, it is further optimized, and the described pervaporation reconcentration process comes from 60% of the two-effect evaporator in the multi-effect evaporation concentration process. % ethylene glycol aqueous solution at a temperature of 100°C, and enters the pervaporation re-concentration process consisting of two-stage pervaporation membranes and components under normal pressure, wherein the ethylene glycol re-concentration solution that has not passed through the first-stage pervaporation membrane is used as In the two-stage pervaporation membrane system, the concentration of ethylene glycol concentrate that has not passed through the two-stage pervaporation membrane reaches 88~90%; while the permeate (condensed water and trace impurities) of the primary and secondary pervaporation membranes ) mixed with the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com