Stabilizer bush

A stabilizer and bushing technology, applied in spring/shock absorbers, multi-purpose hand tools, interconnection systems, etc., can solve problems such as increased friction, easy deformation, easy intrusion of soil, sand, dust, and muddy water, etc., to prevent Longitudinal bending deformation, the effect of suppressing the deformation of the contact surface, and ensuring the tightening margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

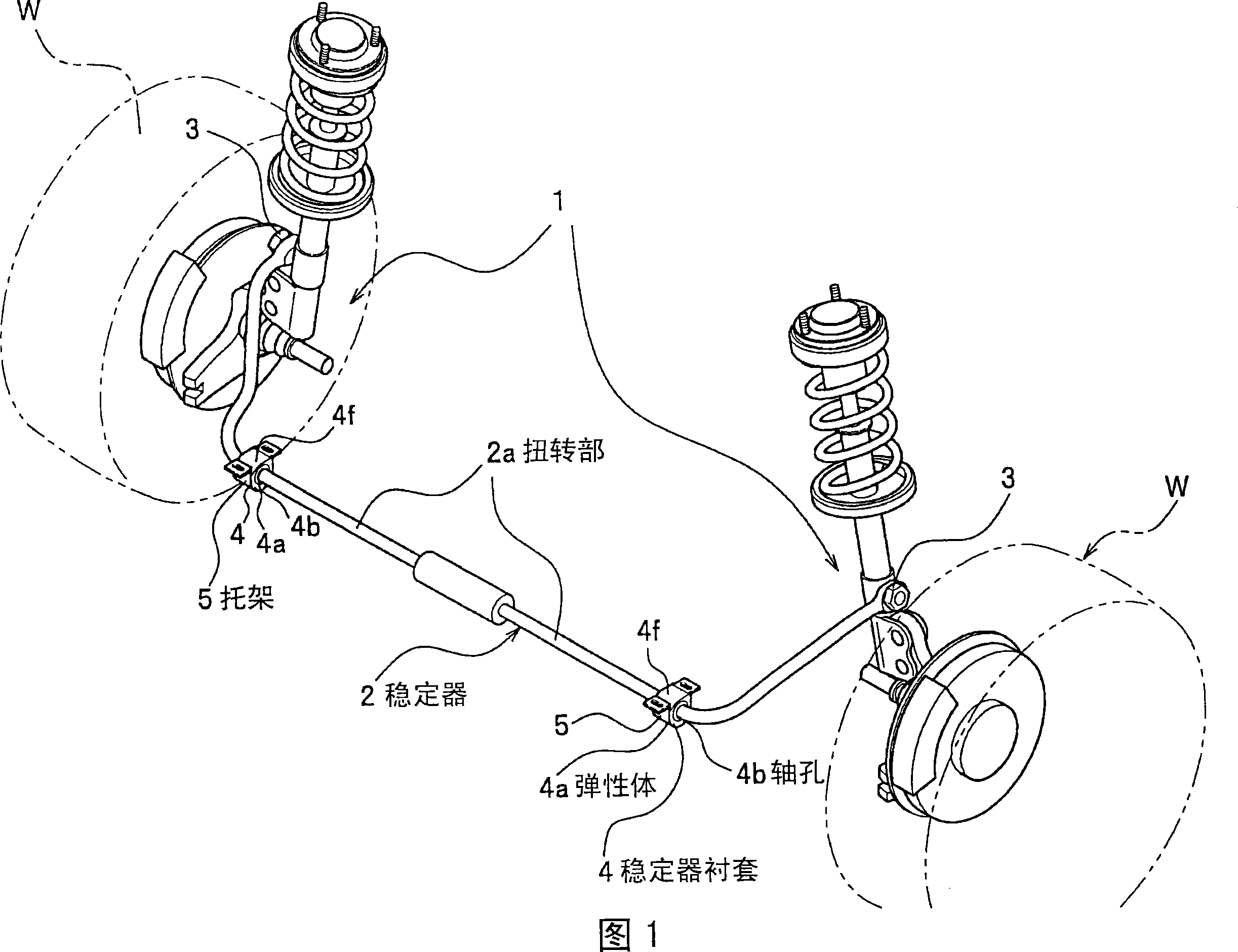

[0054] Hereinafter, the stabilizer bushing according to the embodiment of the present invention will be described with reference to FIGS. 1 to 4. Fig. 1 is a perspective view of a stabilizer showing an installed state of a stabilizer bushing according to an embodiment of the present invention.

[0055] "The composition of the stabilizer"

[0056] As shown in FIG. 1, the stabilizer 2 is a device that suppresses the lateral sway of the vehicle body when the vehicle is turning, and is mounted on the independent suspension 1 of the vehicle body so that the left and right wheels W individually rotate. The stabilizer 2 includes a torsion portion 2a made of a bar-shaped spring member, and bolt insertion holes (not shown) for fastening by bolts 3 are formed at the left and right ends, respectively. Stabilizer bushes 4 are fitted in the middle of the left and right sides of the stabilizer 2.

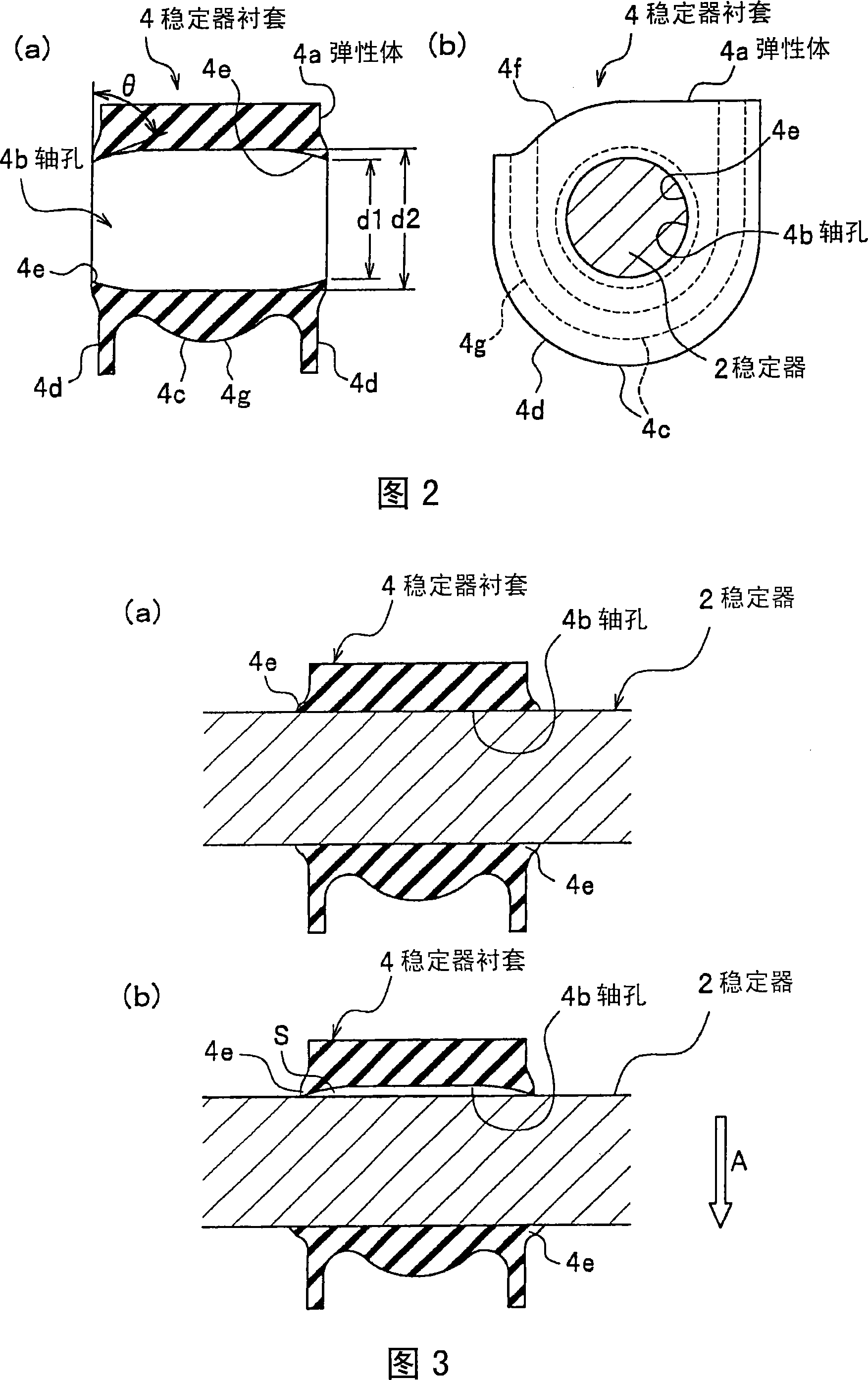

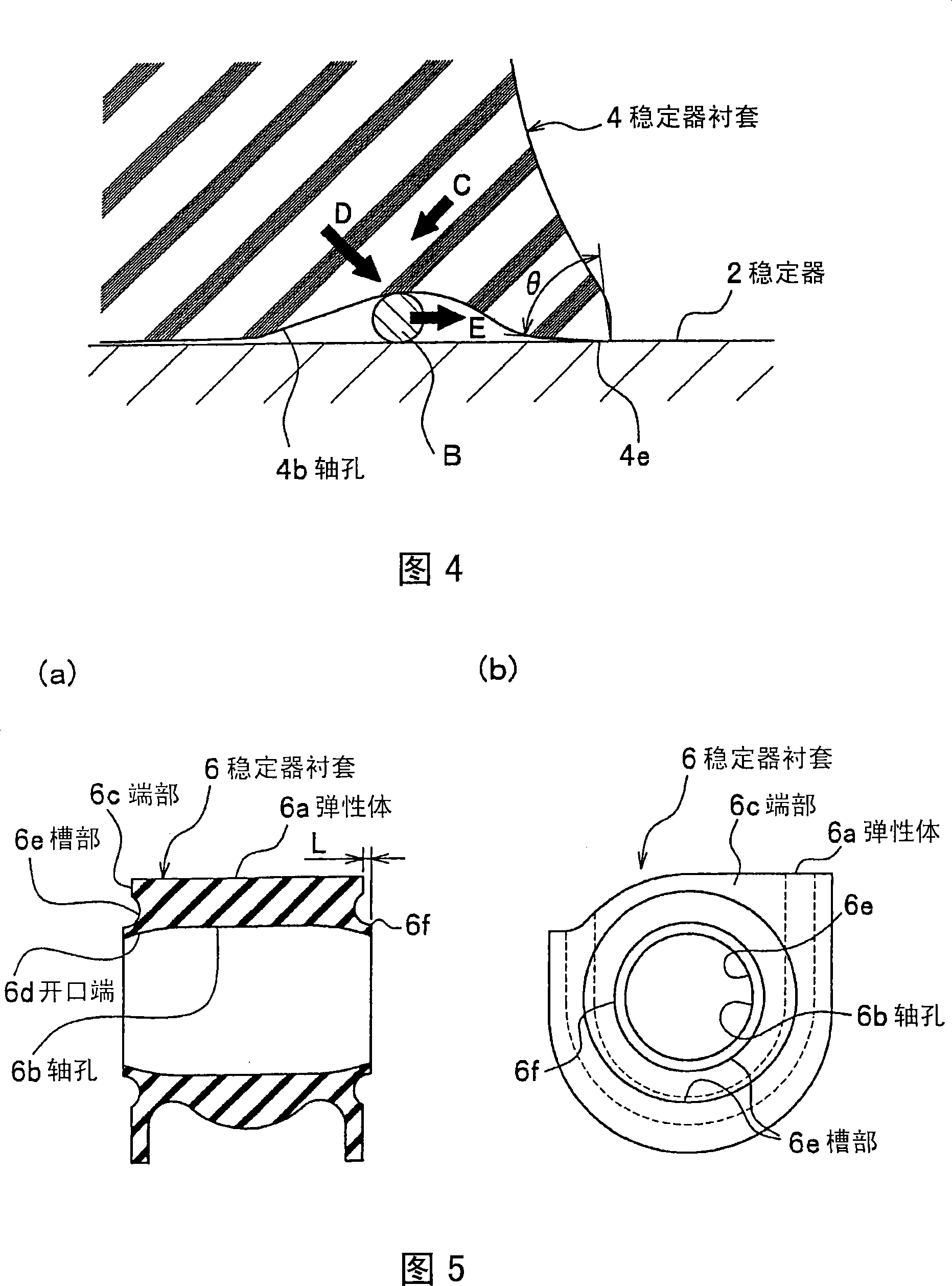

[0057] "Constitution of stabilizer bushing"

[0058] As shown in Fig. 1, the stabilizer bushing 4 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com