Low Vibration Fan

a fan and low-vibration technology, applied in the field of fans, can solve the problems of shortening the lowering the operational stability of the electronic system, and reducing the vibration-damping performance of the rubber column b>95/b>, so as to prolong the service life of the electronic system and reduce nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

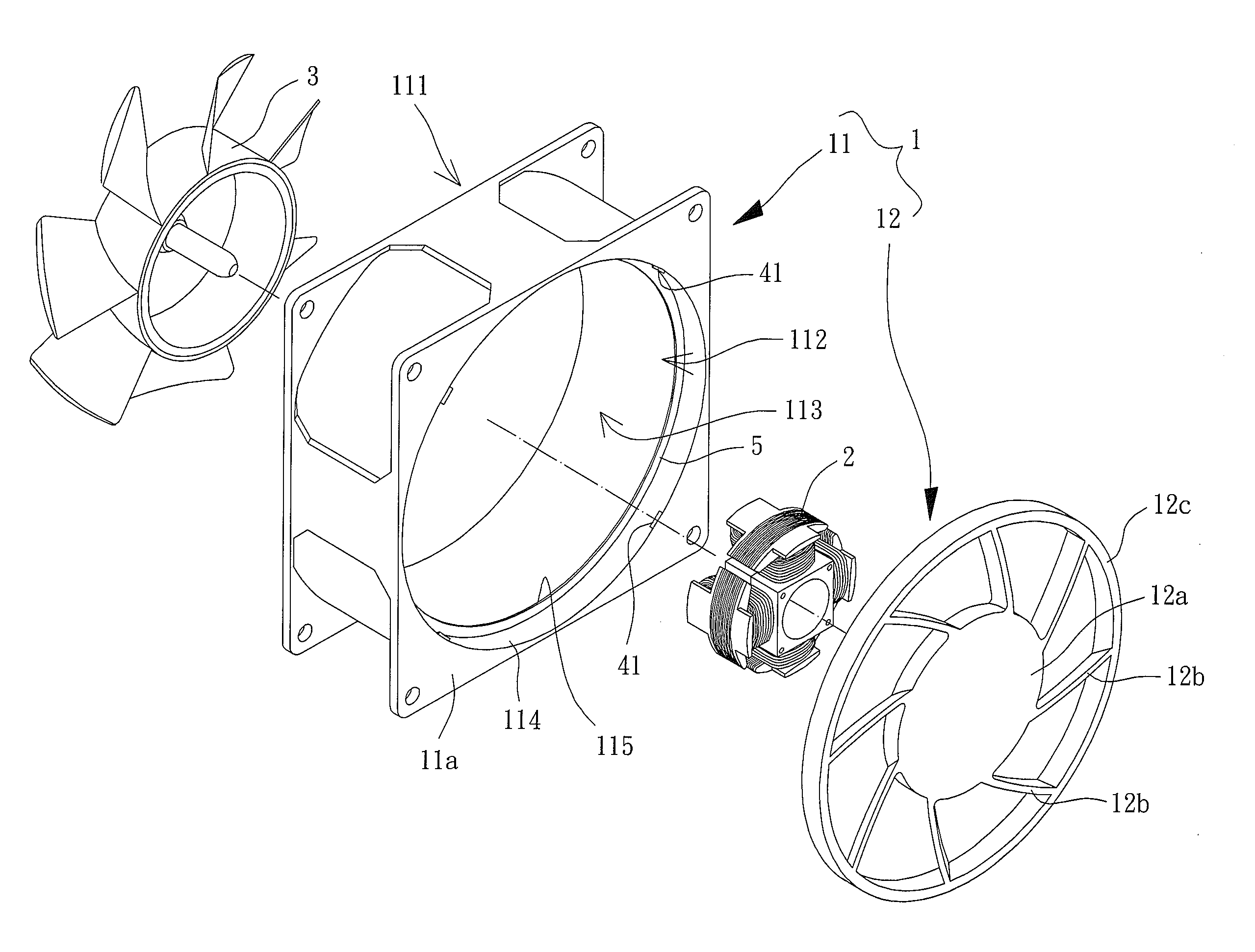

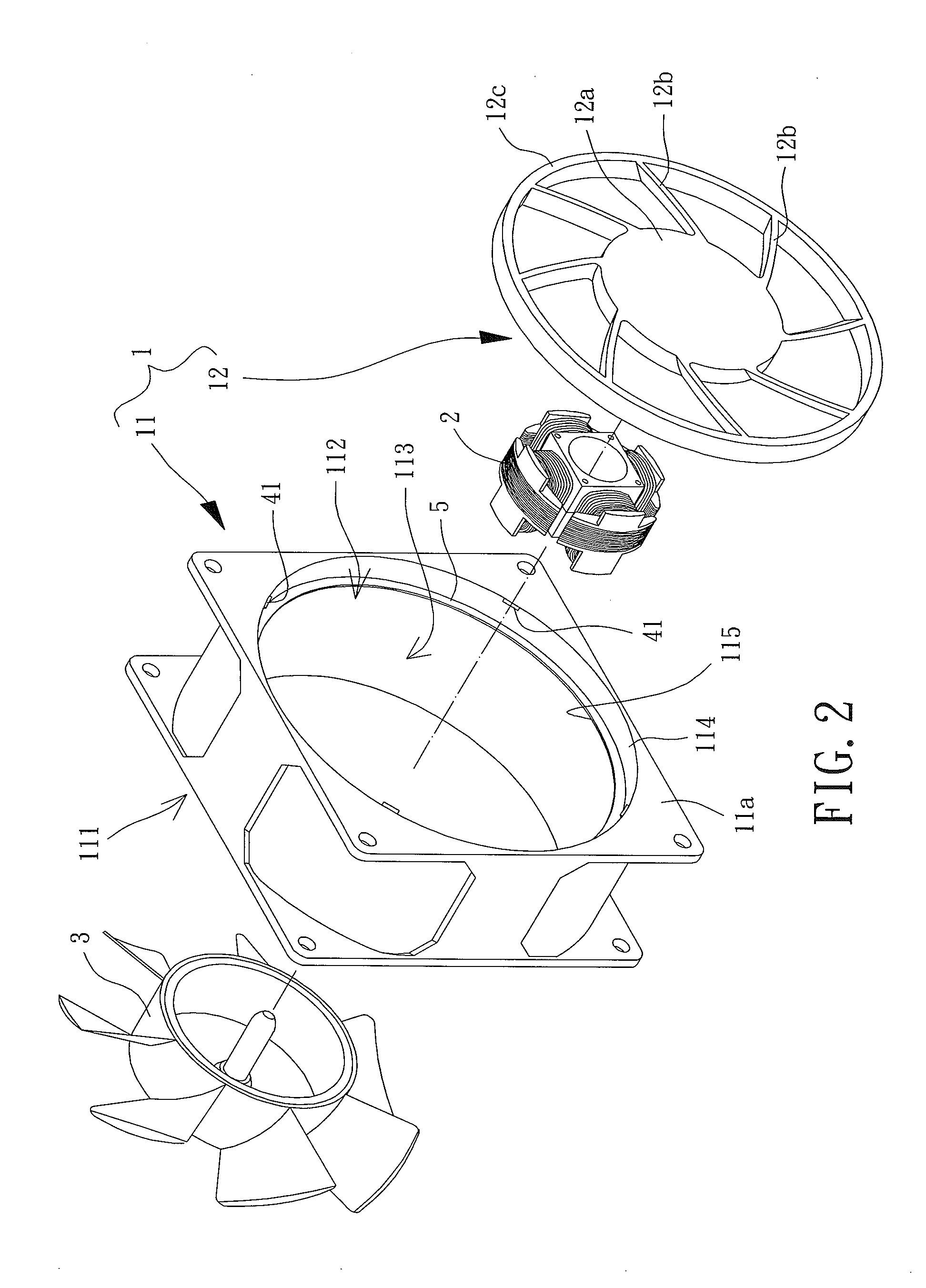

[0036]Referring to FIGS. 2 and 3, a first embodiment of a low vibration fan of the present invention is shown, which includes a housing 1, a driving member 2 and a fan wheel 3. The housing 1 is in a structure for guiding air flows to enter and exit said low vibration fan, such as a housing structure of an axial fan, a centrifugal fan, or an advection fan (which guides air current to flow in and out of the fan in a radial direction), which is shown as that of an axial fan for example in the following illustration.

[0037]The driving member 2 is coupled inside the housing 1. The fan wheel 3 is rotatably mounted on the driving member 2 so as to be turned by the driving member 2. Specifically, a shape of the housing 1 is not limited as long as this shape is capable of receiving the driving member 2 as well as the fan wheel 3. For instance, the housing 1 can be a polygonal shape, a circular shape or an elliptic shape. In the following embodiments, the housing 1 is in a rectangular shape.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com