Treatment method of oily sludge and sand

A treatment method, oil sludge sand technology, applied in sludge treatment, immiscible solvent sludge treatment, water/sludge/sewage treatment, etc., can solve the problem of large mechanical equipment wear, long process, and poor separation effect of oily sludge etc. to achieve the effect of reducing mechanical wear and ensuring the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The raw materials used in this example are taken from the oil sludge sand in the production fluid produced by a joint station. The properties of the raw materials were analyzed, and the analysis results are shown in Table 1.

[0053] Table 1.

[0054]

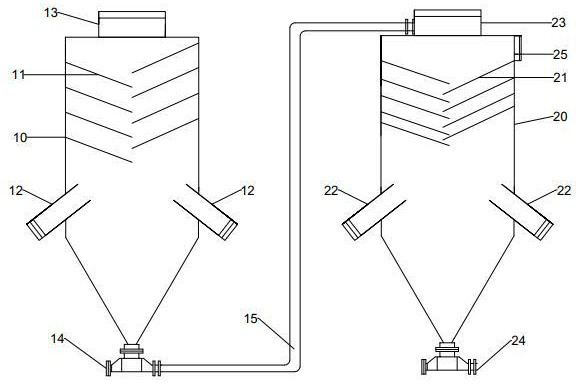

[0055] The above-mentioned oil sludge sand is processed sequentially through the feeder, sand washer and impeller agitator. The structure diagram of the feeder and sand washer is shown in figure 1 Shown:

[0056] The upper part of the feeder cylinder 10 is a cylindrical tank body and the lower part is a conical tank body. The feeder inlet 13 is set at the top center of the cylindrical tank body, and 8 staggered arrangements are arranged on both sides of the inner wall above the tank body. The feeder distribution plate 11, the feeder distribution plate 11 is arranged in the range from the top of the cylindrical tank body to the height of 1 / 2 cylindrical tank body from the top; the feeder distribution plate 11 is down...

Embodiment 2

[0064] In this embodiment, the scum produced by a refinery sewage treatment plant is used as the raw material of the oil sludge sand. The properties of the raw materials were analyzed, and the analysis results are shown in Table 3.

[0065] table 3.

[0066]

[0067] The above-mentioned oil sludge sand is processed sequentially through the feeder, sand washer and impeller agitator. The structure diagram of the feeder and sand washer is shown in figure 1 Shown:

[0068] The structure of the feeder and the sand washer is different from that in Example 1 in that the height of the cylindrical tank body of the feeder and the sand washer is different, and the distribution plate 11 of the feeder is 7 pieces, so as to form a 60° direction with the horizontal direction. The height of the gap between two adjacent feeder distribution plates 11 on the same side is 200mm; the distribution plate 21 of the sand washer is inclined downward at 15° from the horizontal direction, and the tw...

Embodiment 3

[0074] The raw materials used in this example are the raw materials used in Example 1 and Example 2 through equal mass mixing as oil sludge sand raw materials. The properties of the raw materials were analyzed, and the analysis results are shown in Table 5.

[0075] table 5.

[0076]

[0077] The above-mentioned oil sludge sand is processed sequentially through the feeder, sand washer and impeller agitator. The structure diagram of the feeder and sand washer is shown in figure 1 Shown:

[0078] The structure of the feeder and the sand washer is different from that in Example 1 in that the height of the cylindrical tank body of the feeder and the sand washer is different, and the distribution plate 11 of the feeder is 9 pieces, so as to form a 45° direction with the horizontal direction. The height of the gap between two adjacent feeder distribution plates 11 on the same side is 260mm; the distribution plate 21 of the sand washer is inclined downward at 15° from the horizont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com