Multifunctional mechanical automatic mold processing device

A technology for multi-functional machinery and mold processing, applied in grinding drives, metal processing equipment, grinding/polishing safety devices, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

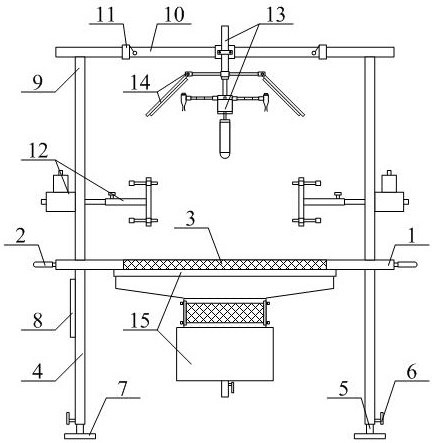

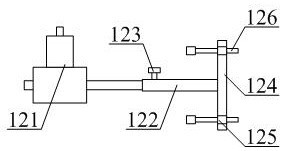

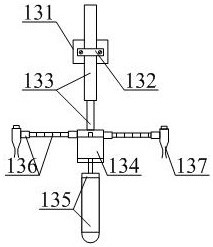

[0034]Below in conjunction with accompanying drawing, the present invention is described in detail, as shown in accompanying drawing 1 and accompanying drawing 2, a kind of multifunctional mechanical automatic mold processing device comprises frame 1, adjusting handle 2, filter screen 3, support pipe 4, adjusting bar 5. Adjusting bolt 6, support foot 7, automatic control panel 8, stand 9, linear slide rail 10, limit switch 11, adjustable mold blank clamping flip plate structure 12, adjustable water spray washing grinder Structure 13, an adjustable anti-splash protective cover structure 14 and a waste liquid collection anti-fouling temporary storage box structure 15, the four corners of the outside of the frame 1 are horizontally threaded with adjustment handles 2; the frame 1 The filter screen 3 is screwed in the middle position of the interior; the four corners of the bottom of the frame 1 are longitudinally threaded with a support tube 4; the inner lower side of the support t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com