Ethylene cryogenic separation method for large-sized ethylene device

An ethylene plant, cryogenic separation technology, applied in the direction of cold treatment separation, refrigeration and liquefaction, liquefaction, etc., can solve the problems of manufacturing, transportation, installation difficulties, manufacturing difficulties, large size of the cold box, etc., to reduce equipment investment and operation cost, reduce the stress concentration of the nozzle, and facilitate the effect of manufacturing and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

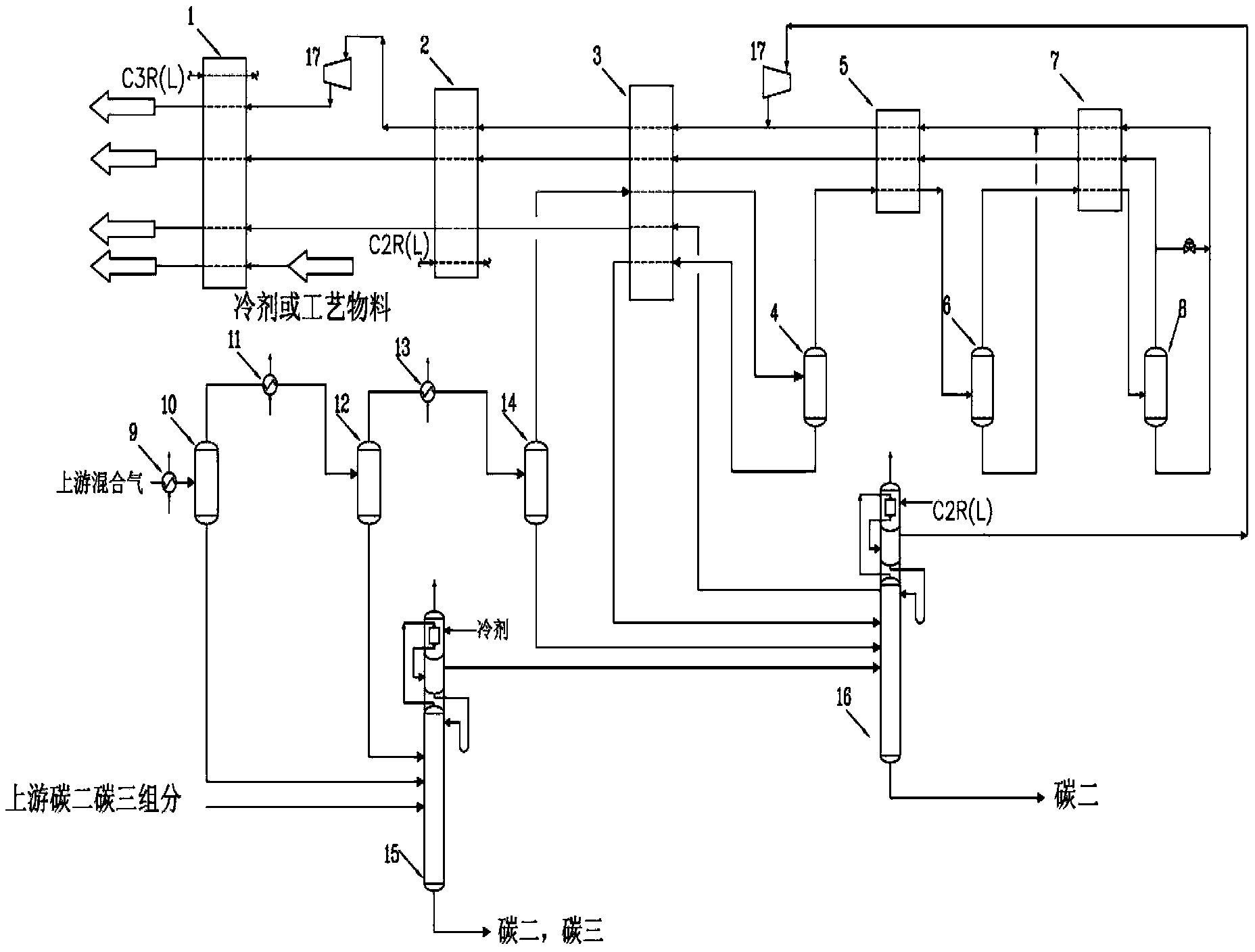

[0030] Example 1

[0031] Such as image 3 As shown, the mixed gas containing C2, C3, hydrogen, and methane from the tubular cracking furnace or heavy oil catalytic cracking or coal-to-olefin process is first compressed, dried and pre-cooled to about -20°C, and then passed through a cooler 9 After cooling to about -50°C, it enters the component separation vessel 10, where the gas phase (mainly composed of carbon two, carbon one and hydrogen) and liquid phase (mainly composed of carbon one, carbon two, C3 and hydrogen), the gas phase enters the cooler 11 and is cooled to -73°C and then sent to the component separation vessel 12, and the liquid phase is sent to the pre-demethanizer 15; in the component separation vessel 12, it continues to separate into gas and liquid phases, The gas phase from the top of the component separation vessel 12 is cooled to -95°C by the cooler 13 and then enters the component separation vessel 14. The liquid phase obtained from the bottom of the compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com