Flow controllable epoxy resin prepreg and preparation method thereof

A technology of epoxy resin and epoxy resin system, which is applied in the field of composite materials, can solve the problems of low molding efficiency and large quality fluctuation of composite material parts, and achieve enhanced compatibility, good commercial application prospects, and reduced manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

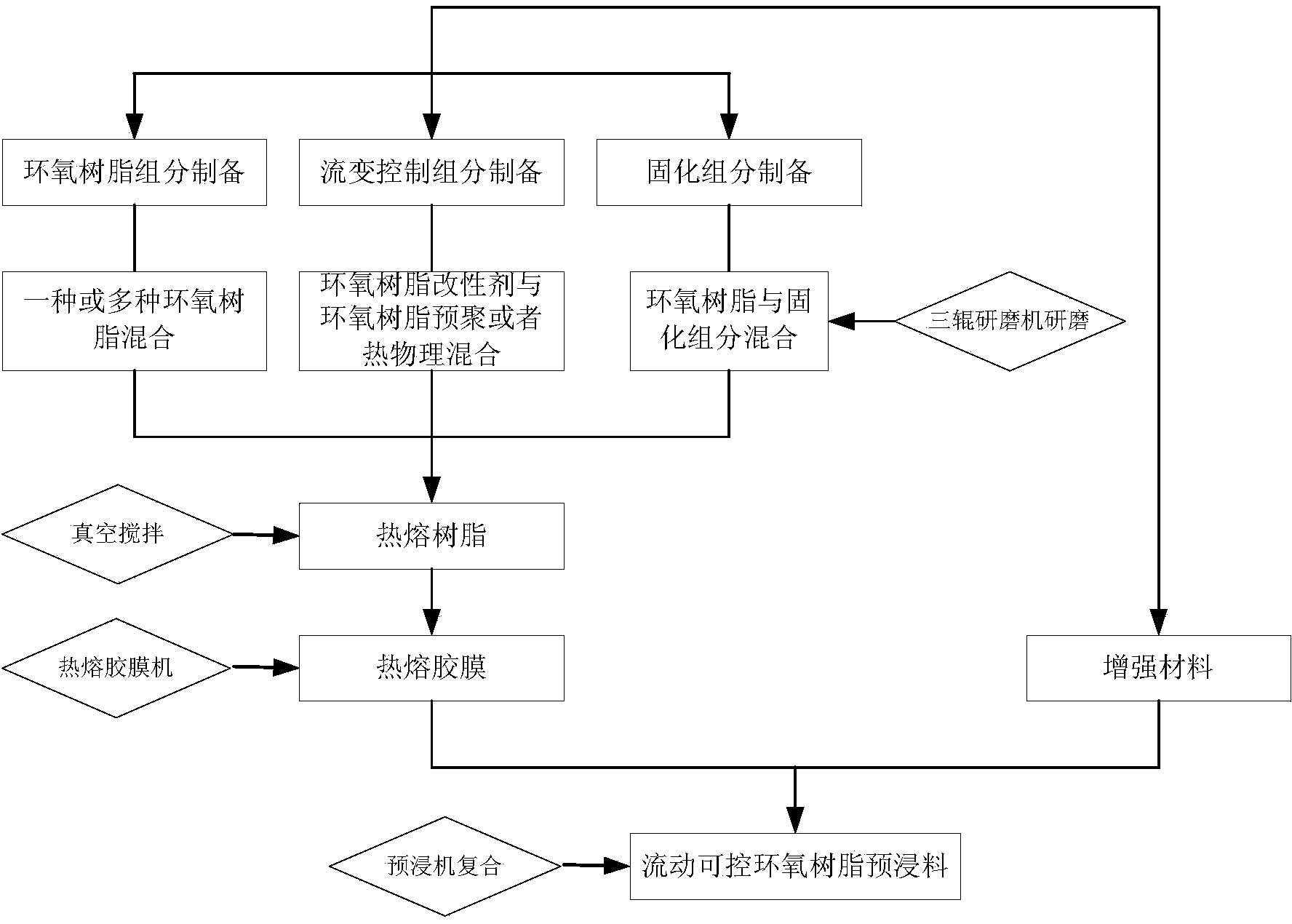

Method used

Image

Examples

Embodiment 1

[0040] Example 1: A flow controllable epoxy resin prepreg is composed of F-46 epoxy resin, CYD-011 epoxy resin, carboxyl-terminated nitrile rubber, DYD-128 epoxy resin and curing agent dicyandiamide The flow controllable epoxy resin system is impregnated with reinforcing materials. The preparation steps are as follows: (1) Stir F-46 epoxy resin and CYD-011 epoxy resin at 50-100°C and 200-1000r / min for 0.5-1h and mix uniformly. The content is 25%, and the content of CYD-011 epoxy resin is 15%; (2) The carboxyl-terminated nitrile rubber and CYD-011 epoxy resin are heated at 100-150℃ and 200- under the action of the catalyst triphenylphosphine. Stirring and pre-polymerizing at 1000r / min for 1-3h to prepare rheology control components; wherein the content of CYD-011 epoxy resin is 30%, the content of carboxy-terminated nitrile rubber is 8%, and the content of triphenylphosphine The content is 0.1%; (3) Put DYD-128 epoxy resin into a dry stirring tank and stir for 0.5-2h at 40-50℃ ...

Embodiment 2

[0044] Example 2: A flow controllable epoxy resin prepreg is a flow controllable composition composed of 638s epoxy resin, 830 epoxy resin, polyethersulfone, DYD-128 epoxy resin and curing agent diaminodiphenylmethane Epoxy resin system is impregnated with reinforcing materials. The preparation steps are as follows: (1) Stir 638s epoxy resin and 830 epoxy resin at 50-100°C and 200-1000r / min for 0.5-1h and mix uniformly. The content of 638s epoxy resin is 15%, 830 The content of epoxy resin is 10%; (2) Polyethersulfone and 830 epoxy resin are pre-polymerized at 100-150℃ and 200-1000r / min for 1-3h to prepare rheology control components; The content of 830 epoxy resin is 30%, and the content of thermoplastic resin is 25%; (3) Put the DYD-128 epoxy resin into a dry stirred tank and stir at 40-50℃ and 200-1000r / min. 0.5-2h to obtain low-viscosity DYD-128 epoxy resin, add diaminodiphenylmethane curing agent and stir for 0.5-1h at a speed of 200-1000r / min, then grind 1-5 times on a t...

Embodiment 3

[0048] Example 3: A flow controllable epoxy resin prepreg is made of EX-40 epoxy resin, F-46 epoxy resin, 830 epoxy resin, random carboxyl nitrile rubber, Sb 2 O 3 A flow controllable epoxy resin system composed of particles, dicyandiamide and diuron is impregnated with reinforcing materials. The preparation steps are: (1) Put the EX-40 epoxy resin in a dry container, and stir at a rate of 200-1000r / min for 0.1-3h at 50-100°C to obtain a low-viscosity EX-40 epoxy resin ; Among them, the content of EX-40 epoxy resin is 20%; (2) Prepolymerize F-46 epoxy resin and random carboxyl nitrile butadiene rubber at 100-150℃, 200-1000r / min rotating speed stirring 1- 3h, the rheology control component A is obtained; the content of F-46 epoxy resin is 25%, and the content of random carboxyl nitrile rubber is 10%; (3) Sb 2 O 3 The particles and 830 epoxy resin are stirred at 50-100℃, 200-1000r / min for 0.5-1h and mixed uniformly, and then ground on a three-roll mill for 1-5 times to obtain rheo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com