Preparation method of medium-temperature-curing zero-adhesive-absorption epoxy resin matrix material

A technology for glue epoxy resin and epoxy resin, which is applied in the field of preparation of medium temperature curing zero suction glue epoxy resin matrix material, can solve the problems of uneven resin content and large quality fluctuation, and achieves uniform resin content, excellent performance, The effect of high engineering application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

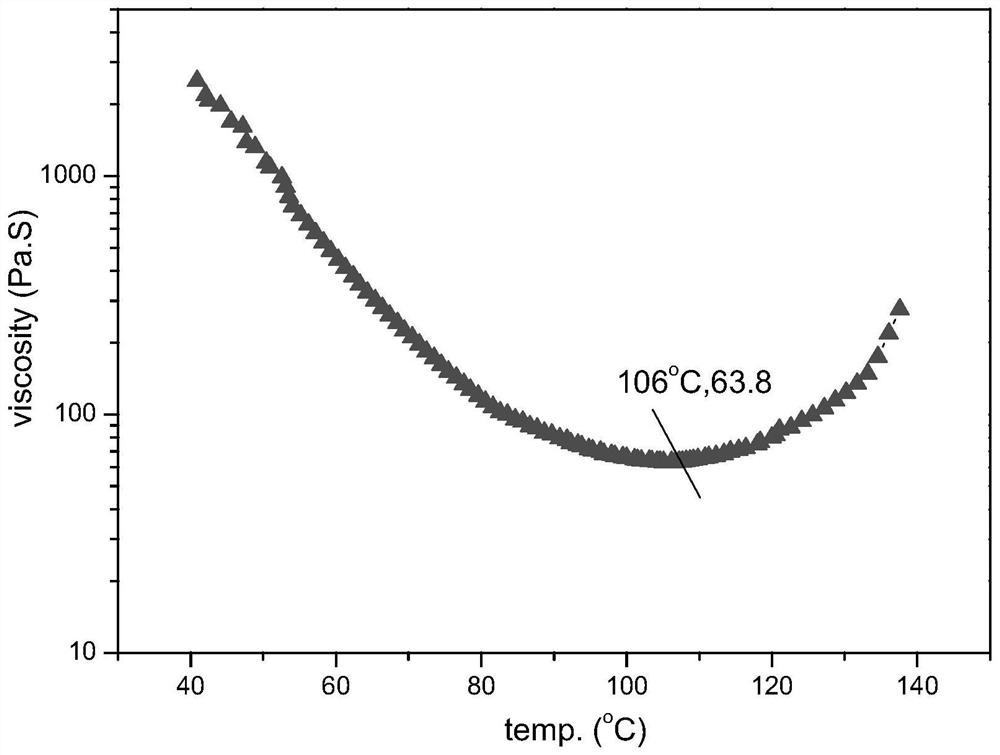

Image

Examples

specific Embodiment approach 1

[0016] DETAILED DESCRIPTION OF THE INVENTION First: The preparation method of temperature curing zero suction epoxy resin matrix material in this embodiment is achieved by the following steps:

[0017] First, the epoxy resin is placed in a dried container, heated at 80-100 ° C and stirred for 1-3 h, resulting in a melted epoxy resin;

[0018] Second, the epoxy resin, epoxy resin modifier, and catalyst are placed in a dried container, heated at 100-200 ° C and stirring for 1-3 hours, resulting in a rheological control component;

[0019] Third, the epoxy resin is placed in a dry container, heated at 40-60 ° C and stirred at 0.5 to 2 h, resulting in a low viscosity epoxy resin, then adding a curing agent or a mixture of a curing agent and an accelerator and stirring 0.5-1 h. , Grind 3-5 times on the three-roller grinder to obtain a curing component;

[0020] 4. The above-mentioned molten epoxy resin, the rheological control component, and the curing component are mixed in a vacuum s...

specific Embodiment approach 2

[0021] DETAILED DESCRIPTION OF THE INVENTION Different: The present embodiment differs from the specific embodiment, and the epoxy resin described in step one, two and three is bisphenol A epoxy resin, bisphenol F-type epoxy resin, bisphenol S. Epoxy resin, phenolic epoxy resin, epoxy epoxy resin, three functional epoxy resin, tetrafunctional epoxy resin, one or several compositions in an epoxy resin in an oxygen resin. Other steps and parameters are identical to those of the specific embodiments.

[0022] In the present embodiment, the epoxy resin is a composition, and each component is mixed in any than.

specific Embodiment approach 3

[0023] BEST MODE FOR CARRYING OUT THE INVENTION 3: The present embodiment is different from that of the specific embodiment, and the agitation rate in steps 1, two and three is from 500 to 1000 r / min. Other steps and parameters are identical to those of the specific embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com