Damping devices for gas turbine combustors

A damping device and gas turbine technology, applied in gas turbine devices, jet propulsion devices, combustion chambers, etc., can solve the problem of high manufacturing costs, reduce manufacturing risks, optimize cooling and service life performance, and achieve effective damping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

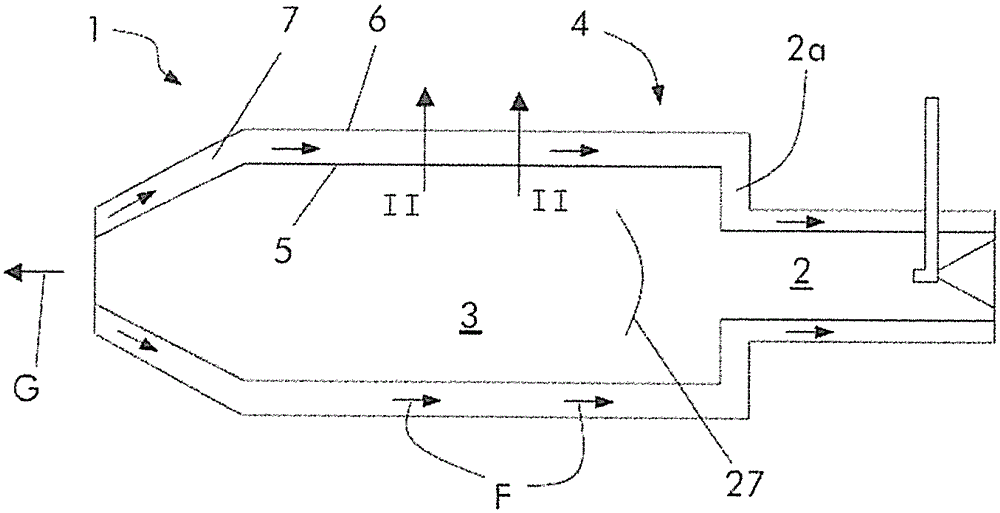

[0042] figure 1 A reheat combustor 1 of a gas turbine with sequential combustion according to the prior art is shown. The burner 1 comprises a burner section 2 axially connected to a combustion chamber 3 . The hot gas flow entering the burner section 2 is fueled by means of fuel supply injectors (eg fuel lances) extending into the hot gas flow and then flows along the mixing zone. The mixture formed in the mixing zone leaves the burner section 2 at its outlet to expand into the combustion chamber 3 . In the combustor 3 the mixture is combusted in a flame 27 generating hot gases G which are expanded in a turbine (not shown).

[0043] The interface between the burner section 2 and the combustion chamber 3 is characterized by a regularly abrupt change in cross-sectional area comprising a vertical front plate extending from the outlet of the burner section 2 to the peripheral wall of the combustion chamber 3 2a. At least a part 4 of the burner wall comprising the burner sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com