Method for checking intensity of wind power locking disk

A locking disc and calibration technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as large errors, discrepancies in actual conditions, and affecting calibration accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

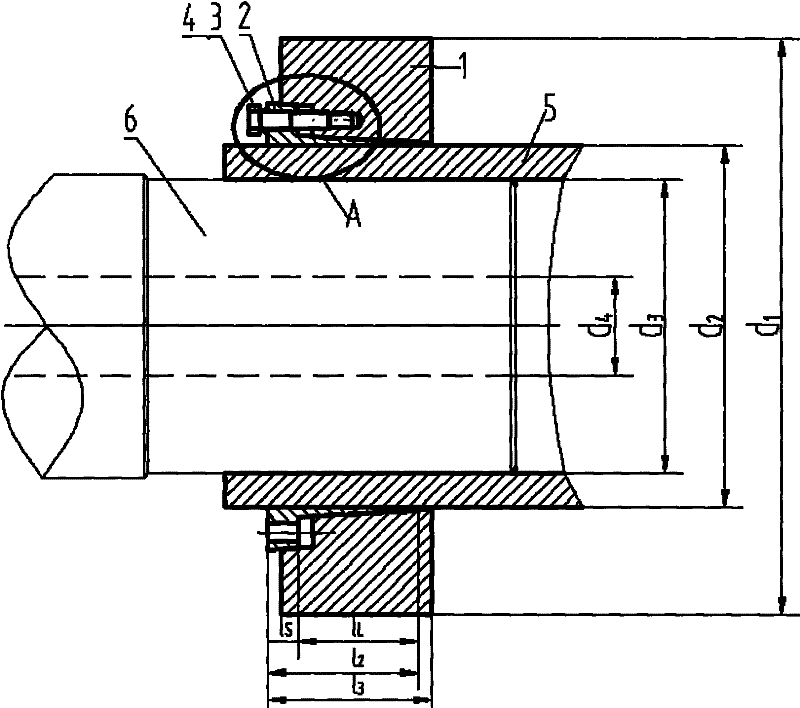

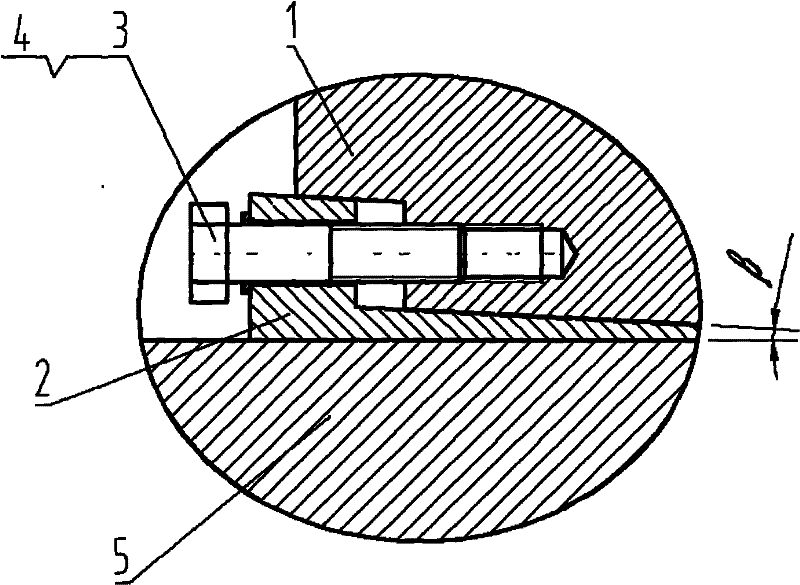

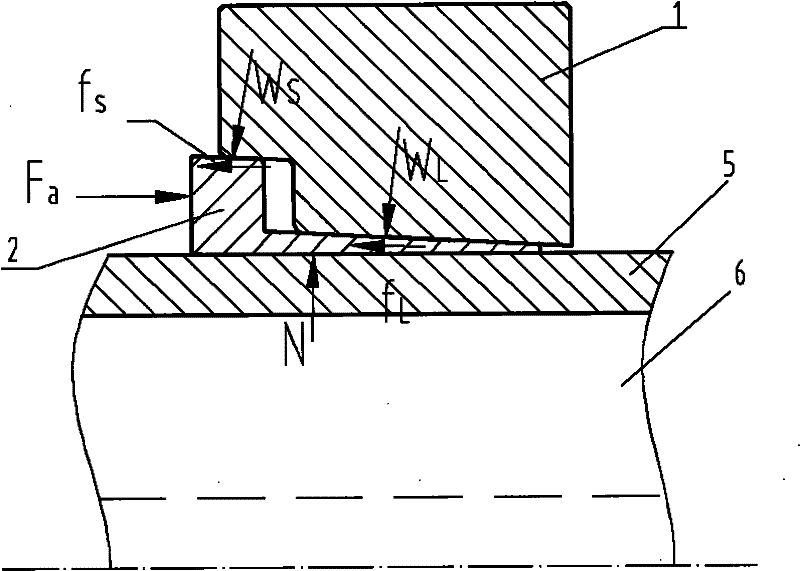

[0152] Now take the 1.5MW wind power locking disc as an example to check its strength. The main parameters are: the outer diameter of the jacket d 1 =1020mm, the average diameter of the long conical surface of the inner ring d mL =662.26mm, the average diameter of the short conical surface d mS =786.00mm, shaft sleeve outer diameter d 2 =640mm, inner diameter d 3 =520mm, spindle outer diameter d 3 =520mm, inner diameter d 4 = 70mm, the elastic modulus of the main shaft, the shaft sleeve, the inner ring and the outer sleeve are all 210GPa, and the Poisson's ratio is all 0.3. The inclination angle of the conical surface of the inner ring β=3°, the design interference of the long conical surface of the inner ring δ L =1.1530mm, short conical surface design interference δ S = 0.8325 mm. Contact length between shaft sleeve and inner ring l 2 =254mm, the effective compression axial length of the contact surface between the main shaft and the sleeve l 3 = 1.1l 2 . The rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com