An early warning method for equipment manufacturing quality problems

A technology for quality problems and equipment manufacturing, applied in the field of management, it can solve the problems of project impact, high cost of correction in the manufacturing plant, lack of experience and reference, etc., to achieve the effect of saving costs, reducing manufacturing risks, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

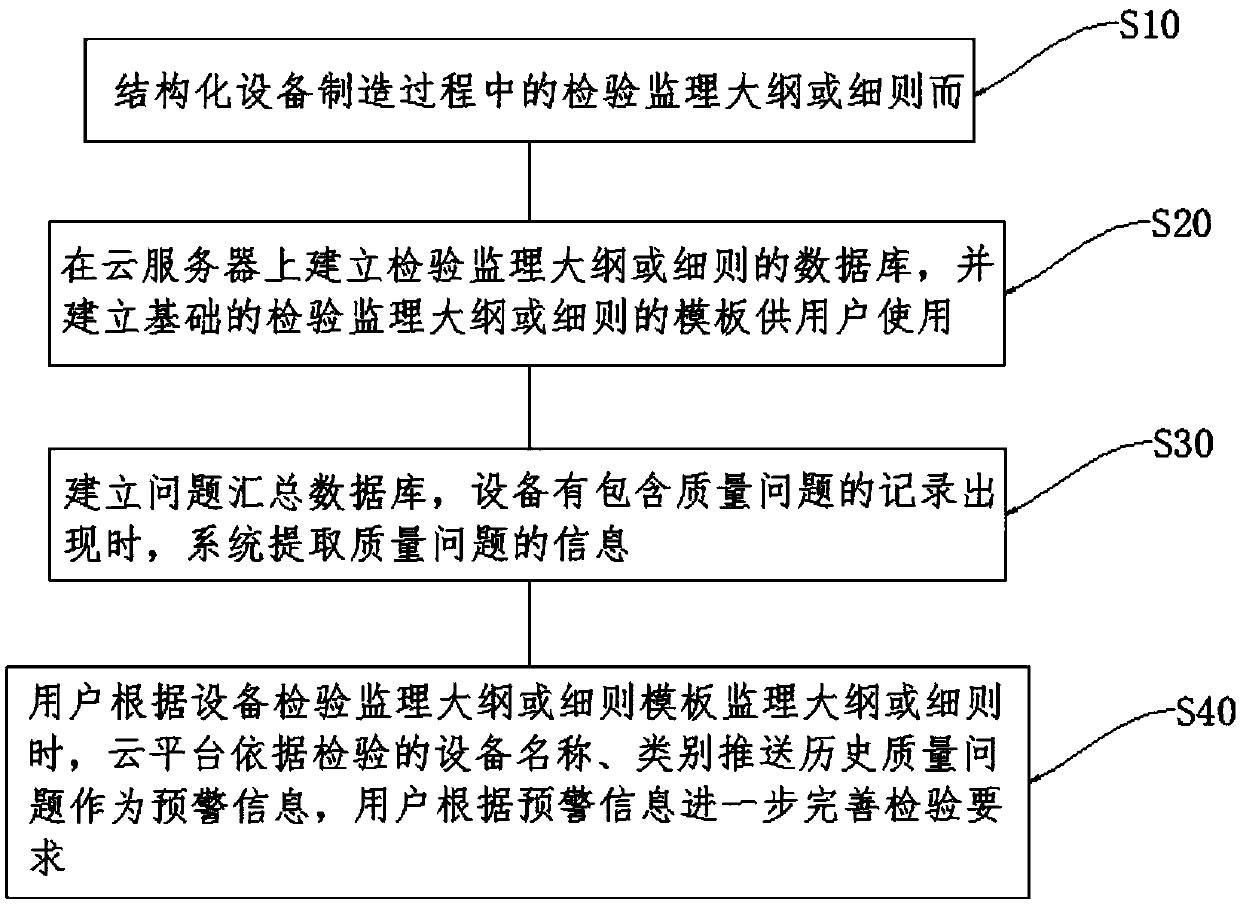

[0017] See figure 1 versus figure 2 , The present invention provides an early warning method for equipment manufacturing quality problems. This embodiment includes at least one computer with a browser and a cloud server. The computer enters the URL in the browser to perform registration and user login to the device to verify ( Supervision) outline (details) in the management system, and then assign permissions for the user modules of the system. The system's early warning method steps for equipment manufacturing quality problems include:

[0018] S10: Inspection and supervision program or detailed rules in the manufacturing process of structured equipment;

[0019] S20: Establish a database of inspection and supervision outline or detailed rules on the cloud server, and establish a basic inspection and supervision outline or detailed rules template for users to use;

[0020] S30: Establish a problem summary database. When the equipment has records containing quality problems, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com