Machining device for back plates of liquid crystal displays of ultra-thin smartphones

A technology for liquid crystal display screens and smartphones, which is applied in the field of processing devices for ultra-thin smartphone LCD screen backplanes to achieve good leveling effects, low product quality, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

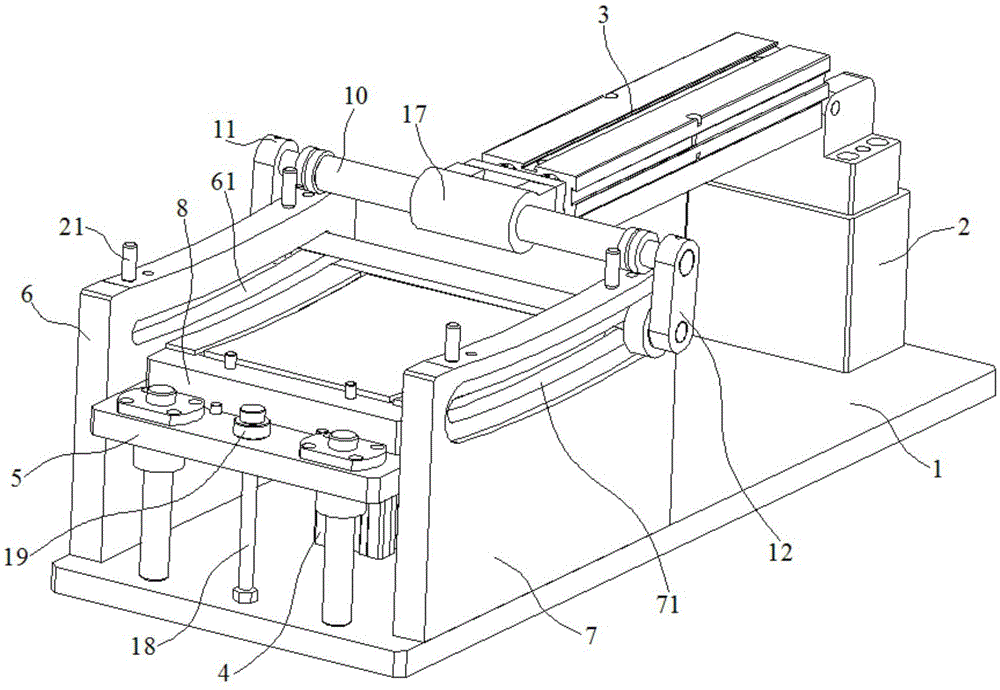

[0019] Embodiment 1: A processing device for the backplane of an ultra-thin smartphone liquid crystal display, including a bottom plate 1, a fixing seat 2, a horizontal cylinder 3, a vertical cylinder 4, a support plate 5 and a left guide rail fixed on the bottom plate 1 Seat 6, right guide rail seat 7, described support plate 5 is positioned between left guide rail seat 6, right guide rail seat 7, and a vertical cylinder 4 below support plate 5 is installed on the bottom plate 1 and the ejector rod of vertical cylinder 4 Connected with the support plate 5, the upper surface of the support plate 5 is covered with an elastic rubber pad 8;

[0020] Left through-hole bar 61 and right through-hole bar 71 are respectively opened on described left guide rail seat 6, right guide rail seat 7, and a rolling shaping rod 9 is positioned at support plate 5 tops and its two ends are respectively embedded in left through-hole bar 61, right In the through-hole bar 71, a connecting shaft 10 i...

Embodiment 2

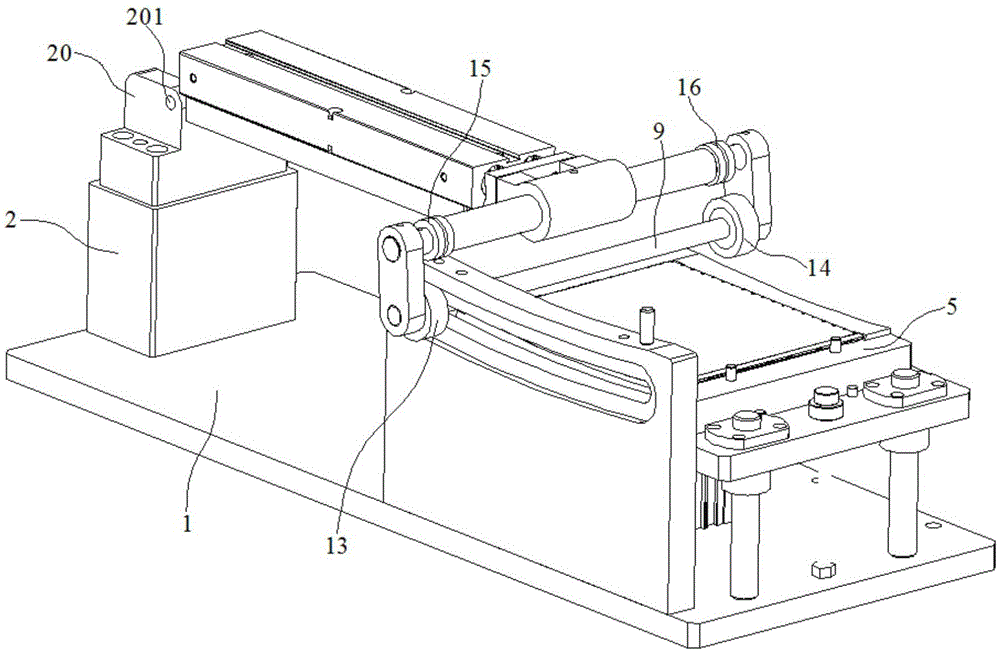

[0025] Embodiment 2: A processing device for the backplane of an ultra-thin smartphone liquid crystal display, including a bottom plate 1, a fixing seat 2, a horizontal cylinder 3, a vertical cylinder 4, a support plate 5 and a left guide rail fixed on the bottom plate 1 Seat 6, right guide rail seat 7, described support plate 5 is positioned between left guide rail seat 6, right guide rail seat 7, and a vertical cylinder 4 below support plate 5 is installed on the bottom plate 1 and the ejector rod of vertical cylinder 4 Connected with the support plate 5, the upper surface of the support plate 5 is covered with an elastic rubber pad 8;

[0026] Left through-hole bar 61 and right through-hole bar 71 are respectively opened on described left guide rail seat 6, right guide rail seat 7, and a rolling shaping rod 9 is positioned at support plate 5 tops and its two ends are respectively embedded in left through-hole bar 61, right In the through-hole bar 71, a connecting shaft 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com