LCD screen backplane leveling mechanism for electronic products

A technology of leveling mechanism and electronic products, which is applied in the field of leveling mechanism of LCD screen backplane, to achieve the effect of good leveling effect, high efficiency and high-quality leveling operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

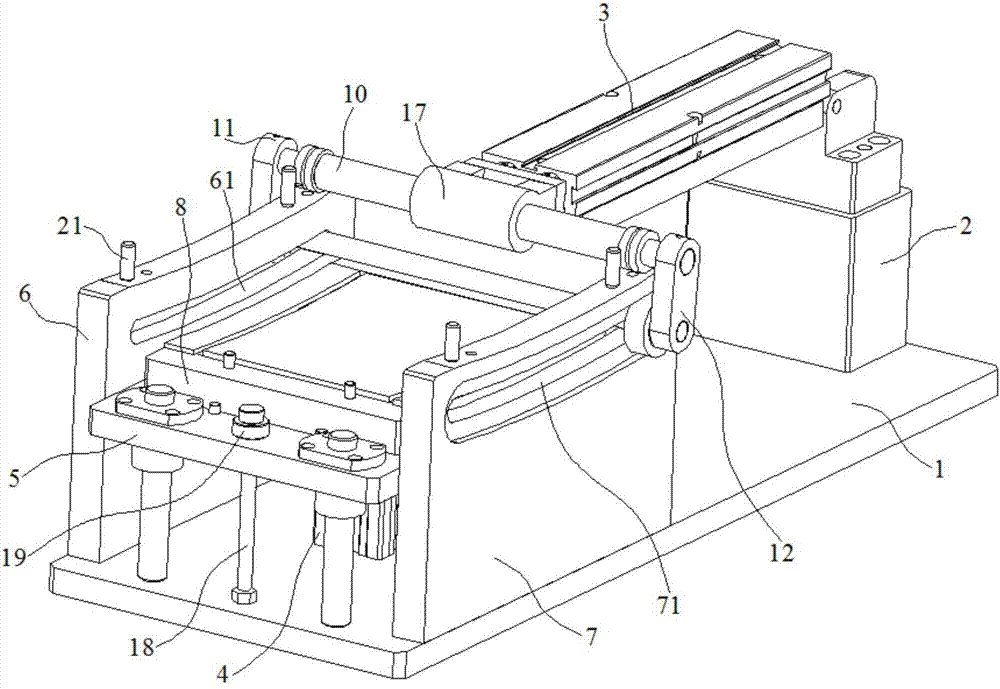

[0020] Embodiment 1: An LCD backplane leveling mechanism for electronic products, including a bottom plate 1, a fixing seat 2, a horizontal cylinder 3, a vertical cylinder 4, a support plate 5, and a left rail seat 6 fixed on the bottom plate 1 , The right rail seat 7, the support plate 5 is located between the left rail seat 6 and the right rail seat 7, a vertical cylinder 4 located below the support plate 5 is installed on the bottom plate 1 and the vertical cylinder 4’s top rod and support The board 5 is connected, and the upper surface of the support board 5 is covered with an elastic rubber pad 8;

[0021] The left guide rail seat 6 and the right guide rail seat 7 are respectively provided with a left through hole strip 61 and a right through hole strip 71. A rolling shaping rod 9 is located above the support plate 5 and its two ends are respectively embedded in the left through hole strip 61 and right In the through-hole strip 71, a connecting shaft 10 is located on the lef...

Embodiment 2

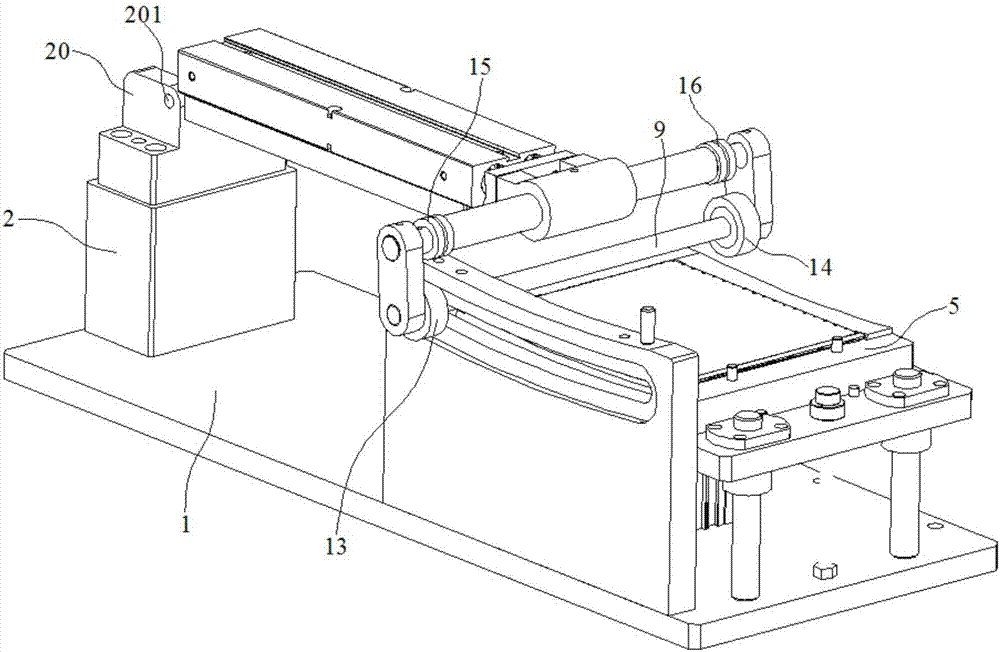

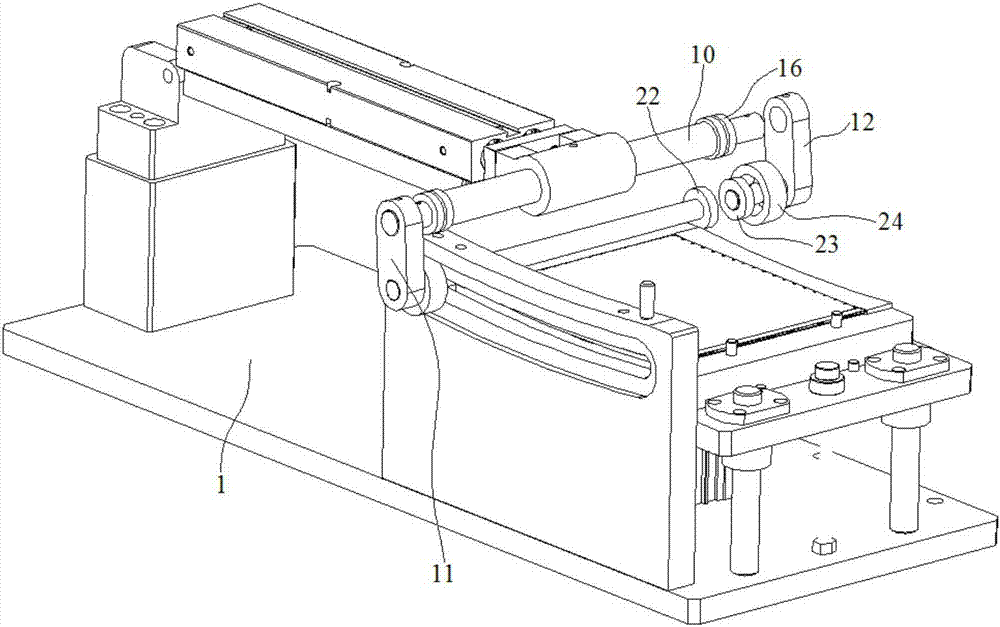

[0026] Embodiment 2: A leveling mechanism for the backplane of an LCD screen for electronic products, including a bottom plate 1, a fixing seat 2, a horizontal cylinder 3, a vertical cylinder 4, a support plate 5, and a left rail seat 6 fixed on the bottom plate 1 , The right rail seat 7, the support plate 5 is located between the left rail seat 6 and the right rail seat 7, a vertical cylinder 4 located below the support plate 5 is installed on the bottom plate 1 and the vertical cylinder 4’s top rod and support The board 5 is connected, and the upper surface of the support board 5 is covered with an elastic rubber pad 8;

[0027] The left guide rail seat 6 and the right guide rail seat 7 are respectively provided with a left through hole strip 61 and a right through hole strip 71. A rolling shaping rod 9 is located above the support plate 5 and its two ends are respectively embedded in the left through hole strip 61 and right In the through-hole strip 71, a connecting shaft 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com