Long mirror installation device

An installation device and strip mirror technology, applied in the field of lithography, can solve problems such as poor flatness of the strip mirror, and achieve the effects of overcoming deformation, reducing processing difficulty and saving material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

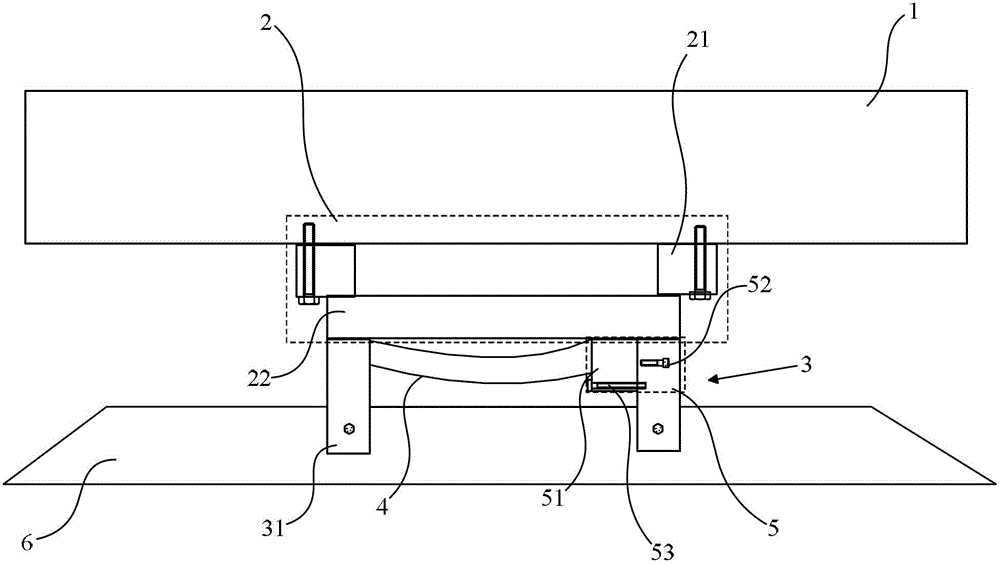

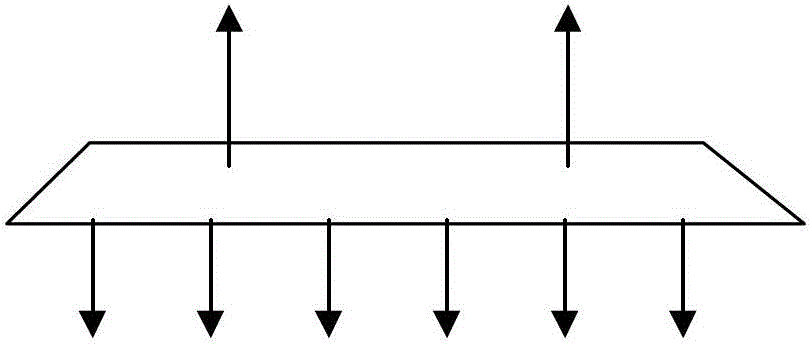

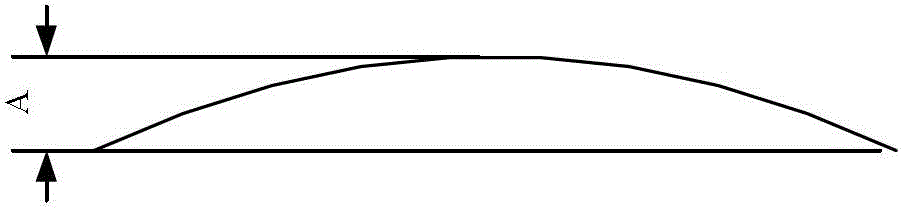

[0033] Please focus on reference figure 1 ,like figure 1 As shown, the embodiment of the present invention provides a strip mirror installation device, which is arranged on the lower surface of the main substrate 1 of the workpiece table of the lithography machine, and includes a three-degree-of-freedom level adjustment device 2, a mounting frame 3, and an elastic reed 4 and a reed deformation adjustment device 5, the three-degree-of-freedom level adjustment device 2 is arranged on the lower surface of the main substrate 1, and the installation frame 3 is arranged on the lower surface of the three-degree-of-freedom level adjustment device 2 , the installation frame 3 is used to fix the long mirror 6 , and the reed deformation adjusting device 5 can adjust the concave-convex degree of the elastic reed 4 so that it can generate different sizes of forces on the long mirror 6 .

[0034]Further, the three-degree-of-freedom level adjustment device 2 includes a three-point levelin...

Embodiment 2

[0042] The difference between the long mirror installation device provided in this embodiment and that in Embodiment 1 is that please refer to Figure 9 and Figure 10 ,like Figure 9 and Figure 10 As shown, the reed deformation adjustment device 5 includes two installation base outer sleeves 51' and two installation base inner sleeves 52', and the two installation base outer sleeves 51' are arranged at intervals along the width direction of the strip mirror 6. On the lower surface of the base 22, the distance between them is greater than the width of the strip mirror 6, and the two mounting base outer sleeves 51' are slidingly connected to the corresponding two mounting base inner sleeves 52' or through internal and external threads. connected, the two ends of the elastic reed 4 are respectively arranged on the two installation base inner sleeves 52', and the installation base inner sleeves 52' can move up and down in the installation base outer sleeve 51', thereby adjusti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com