Machining method for Z-directional multi-axis parts with height differences

A processing method and height difference technology, applied in the field of parts processing, can solve the problems of difficult processing quality to meet design requirements, labor and time-consuming, high repair rate, etc., to achieve accurate flatness, solve processing bottlenecks, and high pass rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

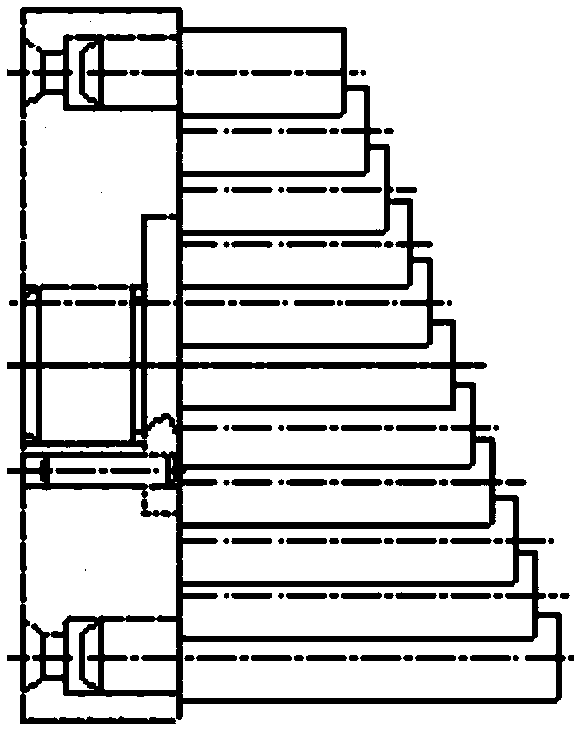

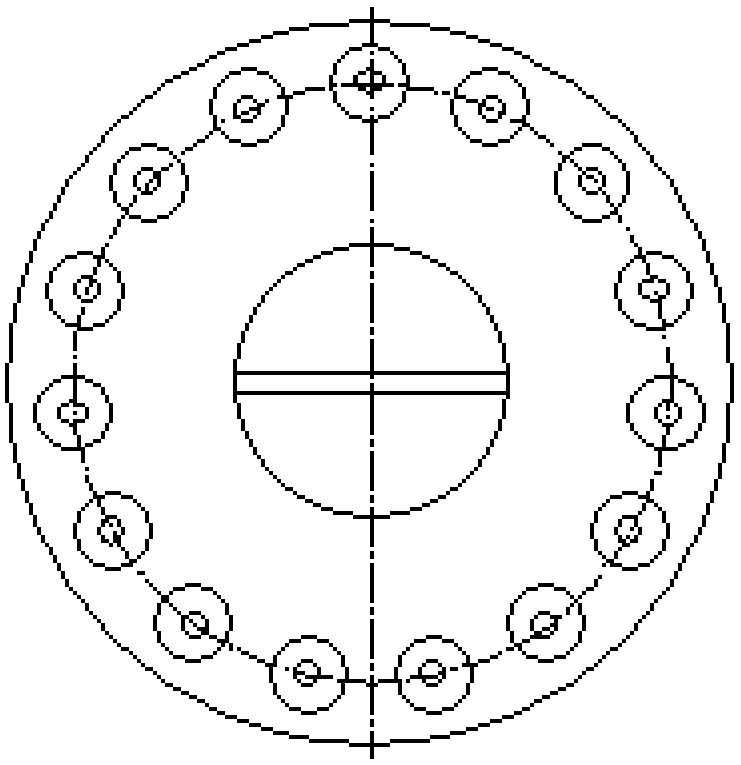

[0018] The invention provides a method for processing a Z-direction multi-axis part with a height difference, the method comprising the following steps:

[0019] 1) The bottom surface of the mounting seat is ground by flat grinding, so that the bottom surface of the mounting seat is the positioning reference plane;

[0020] 2) Install the component with the minimum height in the Z direction on the mounting surface; the mounting surface is opposite to the positioning reference plane; the axis of the component with the minimum height in the Z direction is perpendicular to the positioning reference plane;

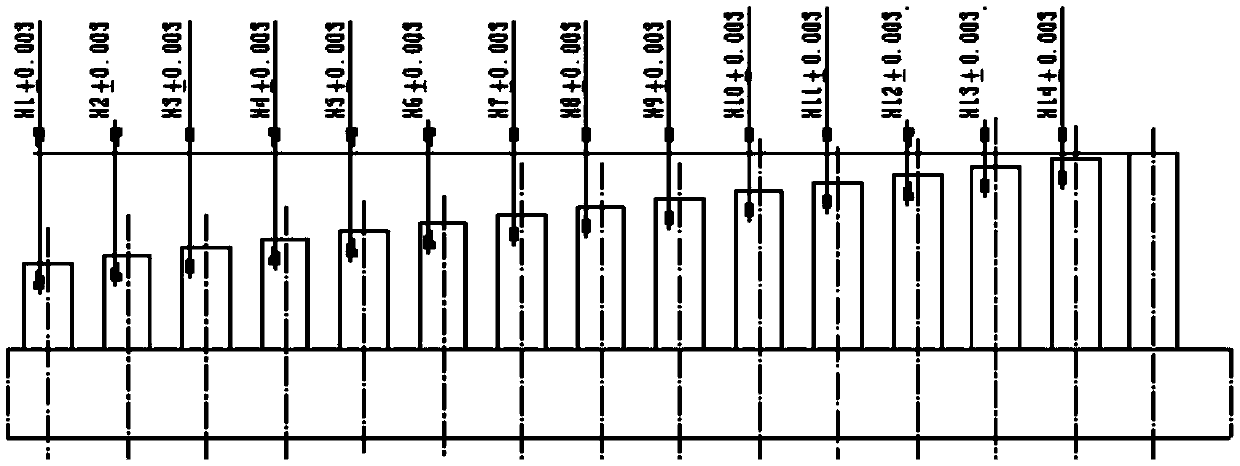

[0021] 3) According to the size requirements of the parts to be processed, take the positioning reference plane as the reference plane, and grind the part on the upper end surface of the component with the minimum height in the Z direction, so that the height of the part with the minimum height in the Z direction is H1 ±0.003mm;

[0022] 4) Install the part with the sub-minim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com