Wall flatness detection device for civil engineering

A detection device and flatness technology, applied in the direction of mechanical roughness/irregularity measurement, application, household appliances, etc., can solve problems such as low efficiency, affecting construction delivery, and consuming a lot of time and manpower, so as to achieve complete functions and increase realism The effect of accuracy and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

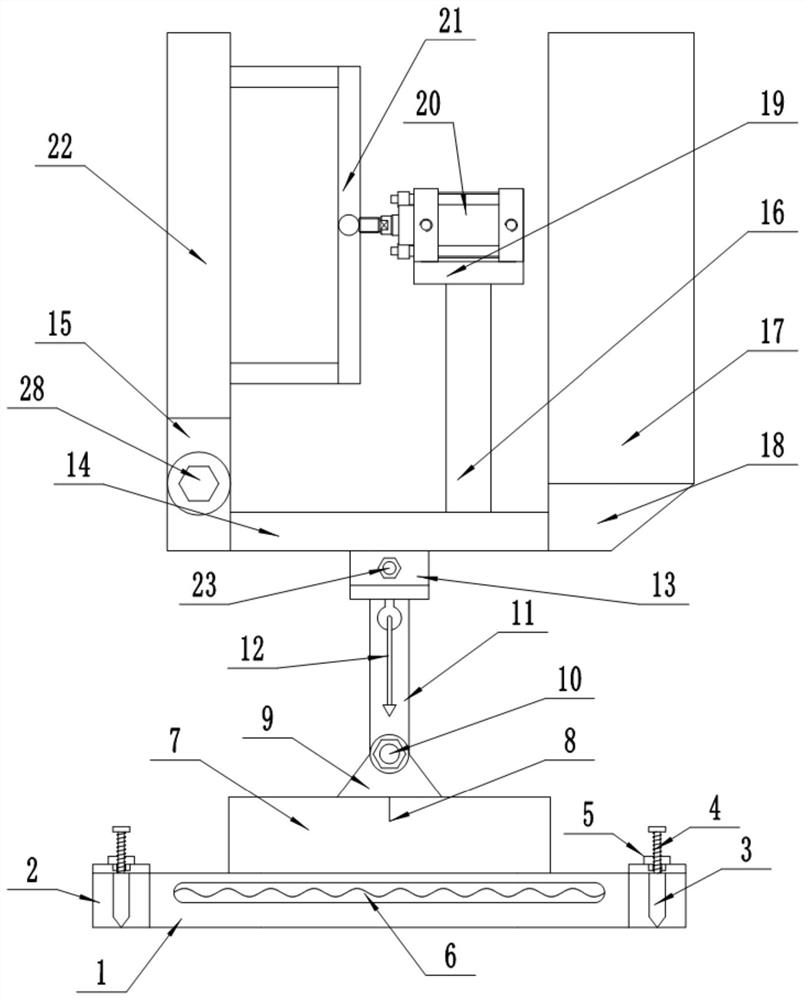

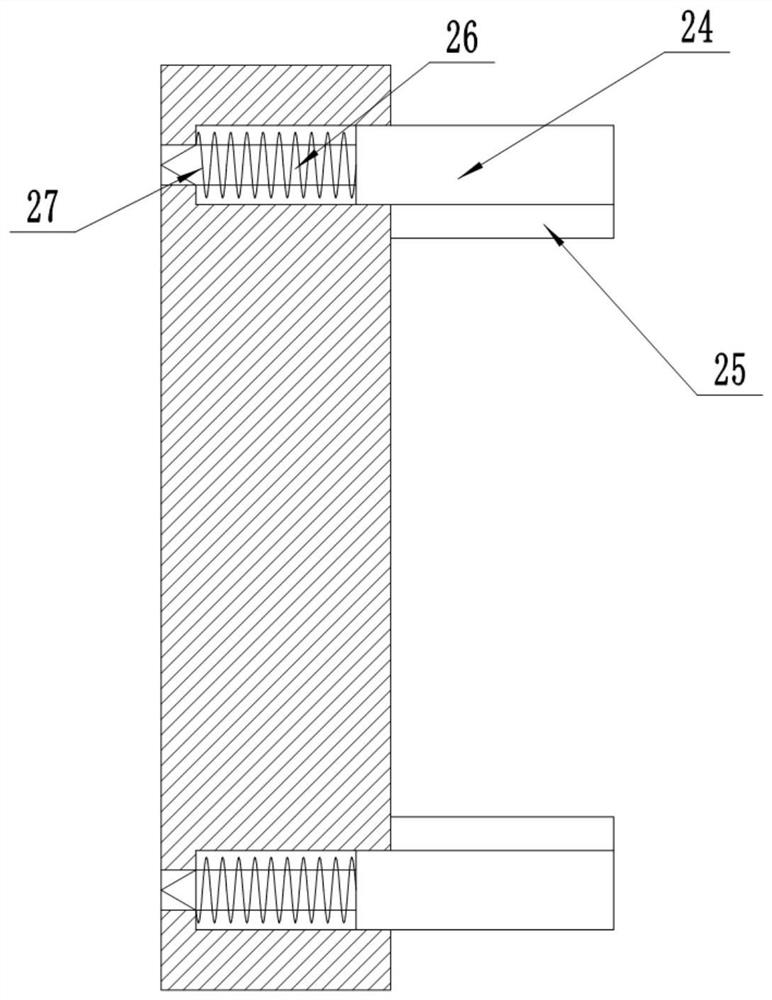

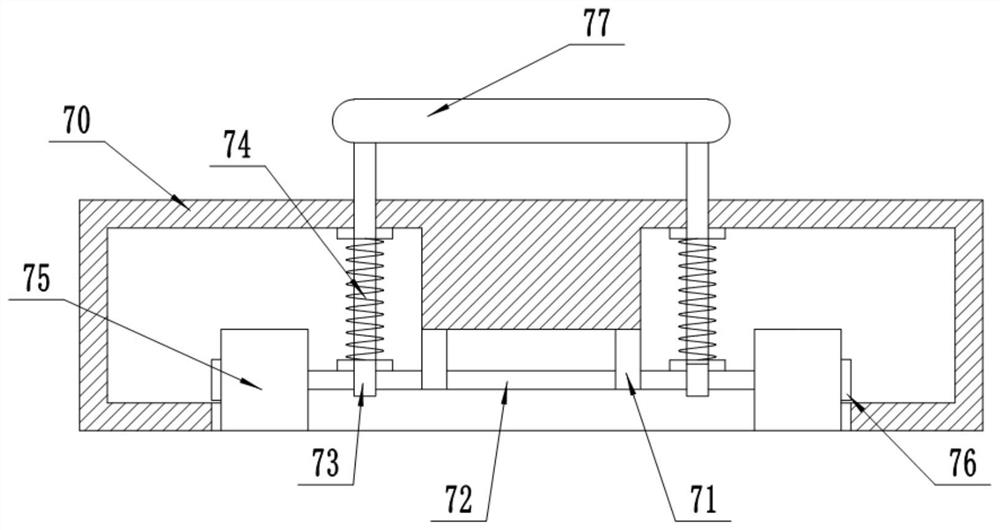

[0020] Such as figure 1 and figure 2 As shown, this specific embodiment adopts the following technical solutions: a wall flatness detection device for civil engineering, including a horizontal base plate 1, an adjustment block 2, an adjustment needle 3, an adjustment bolt 4, a lock nut 5, a level liquid 6, Mobile device 7, calibration line 8, support 9, first locking valve 10, pillar 11, calibration needle 12, rotary sleeve 13, workbench 14, fixed seat 15, bracket 16, ash removal device 17, support platform 18, Cylinder platform 19, cylinder 20, push plate 21, measuring plate 22, second locking valve 23, push rod 24, scale 25, first buffer spring 26, measuring pin 27 and first locking bolt 28; Adjusting blocks 2 are fixedly connected to the left and right sides of the bottom plate 1; adjusting pins 3 are slidingly connected to the front and rear ends of the two adjusting blocks 2, and there are four adjusting pins 3 arranged in a diagonal structure; the adjusting pins The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com