Spinning type reinforcing steel bar automatic straightening machine

An automatic adjustment and spinning technology, applied in the field of steel bar processing, can solve the problems of heavy operating costs, fast loss of straightening blocks, and many wearing parts, and achieves the effect of simple and reasonable structure, extended service life, and easy operation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The spinning type steel bar automatic straightening machine of the present invention will be described in further detail below in conjunction with the accompanying drawings and preferred embodiments.

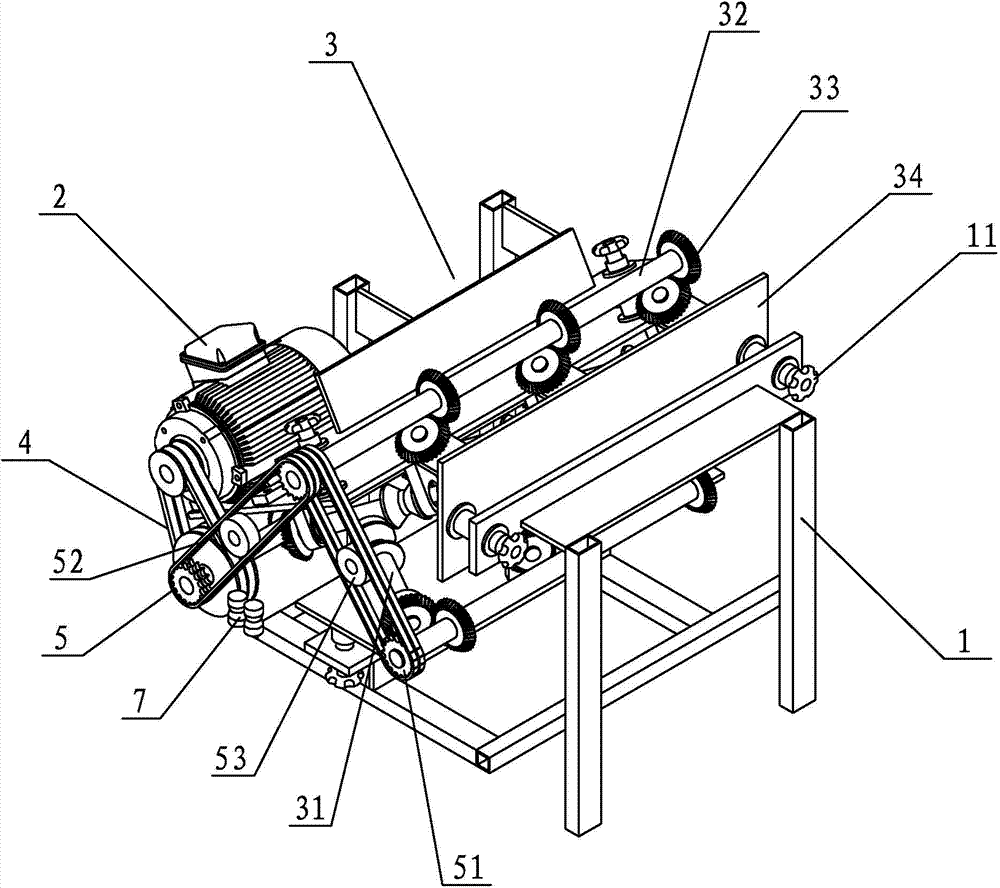

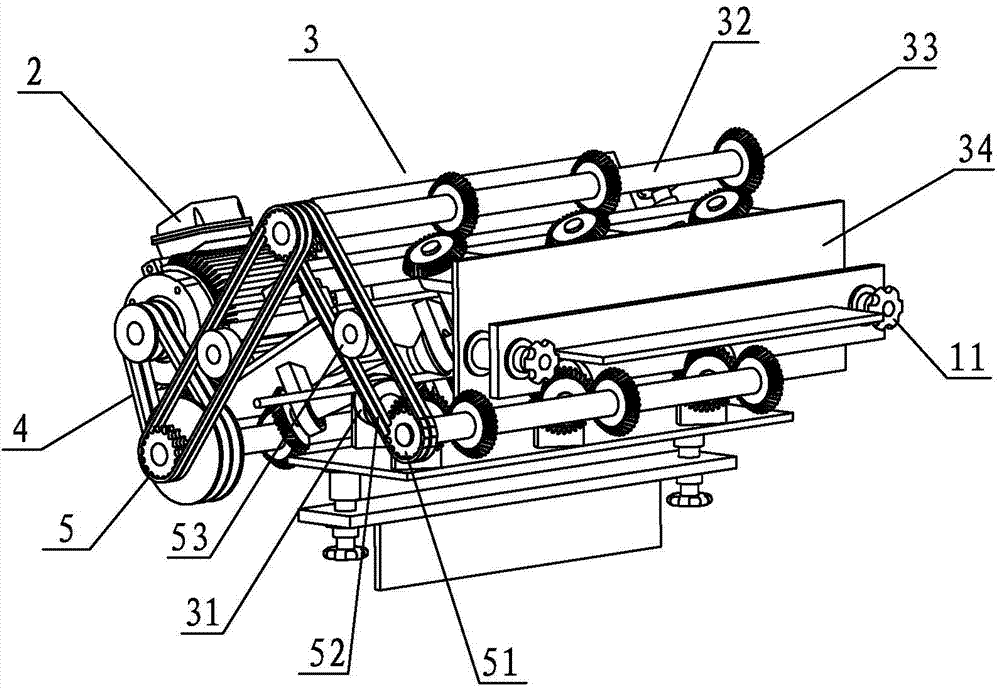

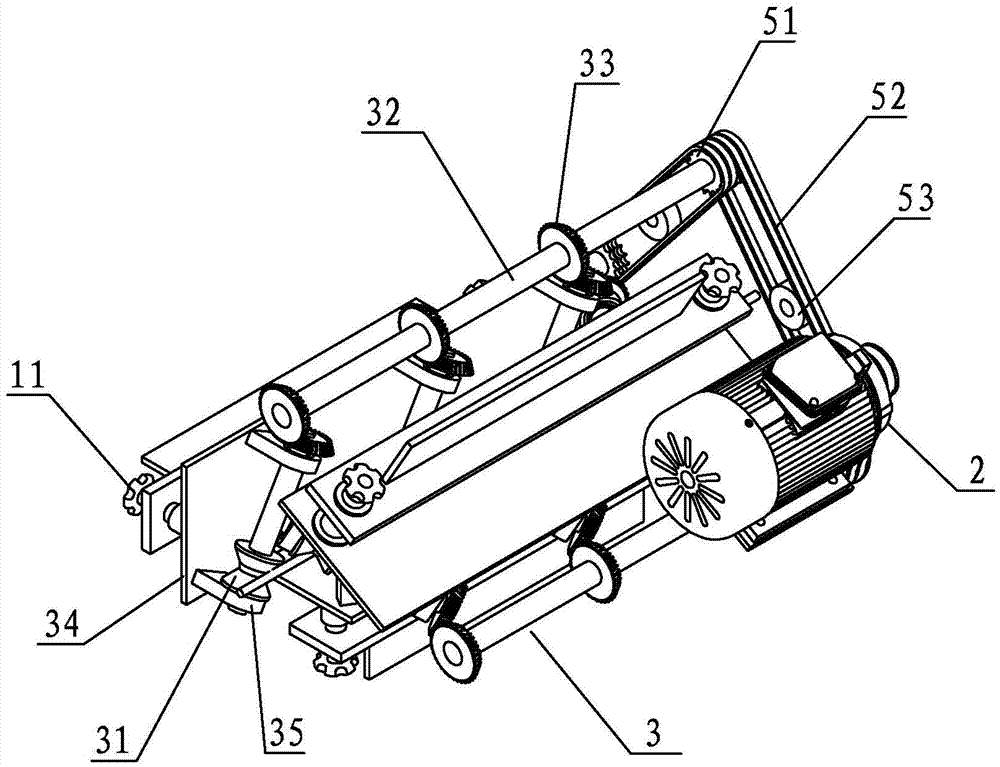

[0026] refer to figure 1 , The preferred embodiment provided by the present invention is a spinning type steel bar automatic straightening machine, which includes a frame 1 and a motor 2, and a straightening mechanism 3 driven by the motor 2 is mounted on the frame 1.

[0027] The straightening mechanism 3 includes at least one group of oblique rollers, each group of oblique rollers is made up of a plurality of oblique rollers 31 in contact with the steel bar 6, refer to Figure 4 to Figure 6 In this embodiment, three groups of oblique rollers are preferably used, and each group is composed of three oblique rollers 31 uniformly distributed on the radial periphery of the steel bar. refer to Figure 5 , the oblique rollers 31 are arranged sequentially along the axial dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com