Plate overlapping straightening process for waved surfaces on two sides of ultra-thin middle-thick plate

A technology of stacking plate straightening and thin gauge, applied in the field of steel rolling, can solve the problems of large unevenness of bearing force, shortened bearing service life, affecting production rhythm, etc., and achieves good straightening effect, effective straightening, and steel plate quality. matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

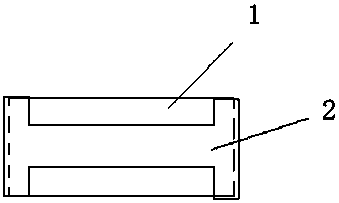

[0018] A 4mm yield strength and 400MPa medium-thick plate double-sided corrugated cold straightening process, the roll diameter and roll distance of the leveler used in this process are 180mm and 240mm respectively. The size of the steel plate is 4×2400×10000mm, the original straightness is about 35mm / 2m, the outer dimension of the stacked plate is 4×2400×10000mm, the width of the middle area in the width direction of the stacked plate is 800mm, and the length of the head and tail is 400mm respectively. After the straightening plate and lining plate are stacked and centered, 8mm, 400MPa and 80% plastic deformation rate are used as the secondary calculation basis in the first pass, and the entrance roll gap is calculated to be -1mm, the exit roll gap is 0mm, and the roll gap After the setting is completed, start the first straightening pass, and lift off the I-shaped liner after the straightening is completed. The second pass uses 4mm, 400MPa and 60% plastic deformation rate as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com