Rotating and straightening method using metal pipe tension

A metal tube and tension technology, applied in the field of straightening of bending deformation, can solve problems such as scratches or indentations on the surface of metal tubes, and achieve the effect of effective straightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Material: Stainless steel tube, annealed condition. The diameter is 10mm, the pipe wall is 08mm, and the pipe length is 1.5m.

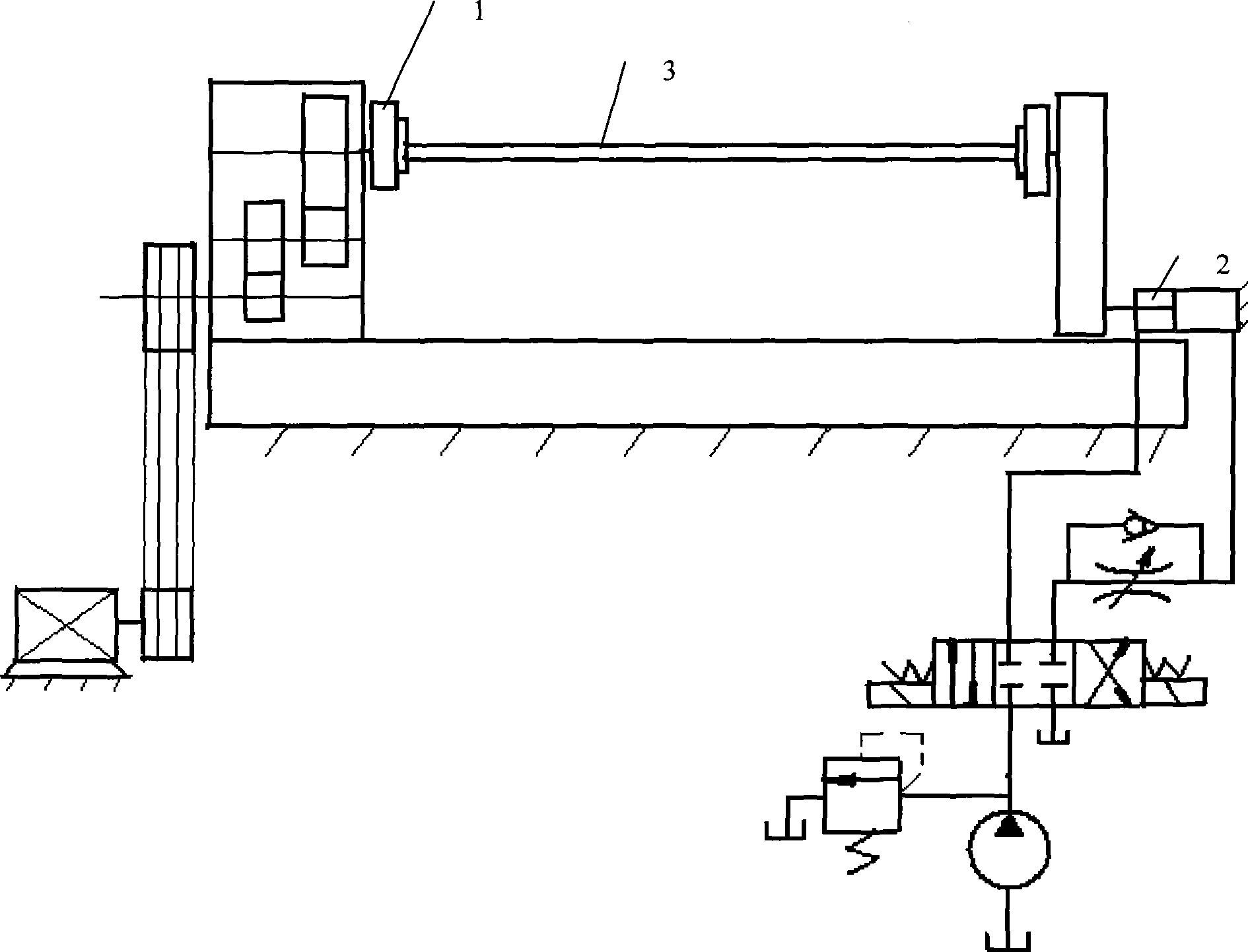

[0011] Straightening equipment: self-made, modified with machine tools. The thimble of the tailstock of the machine tool is changed to chuck 1, and the two ends of the metal pipe 3 are clamped by two chucks at the front and rear (in order to prevent deformation of the metal pipe at the clamping position of the chuck and to have sufficient clamping force, the clamped part at both ends The mandrel should be added to the metal tube and then clamped). A set of hydraulic device is designed, and the hydraulic cylinder 2 piston is pressed against the tailstock to form a stretching tension on the metal pipe. The equipment structure diagram is as follows: figure 1 shown.

[0012] Straightening method: the active chuck drives the metal pipe to rotate, the speed is 1500 rpm, and the tensile tension is 7KN (for this purpose, the pipe reaches the limit ...

Embodiment 2

[0015] Material: Copper tube, annealed condition. The diameter is 6mm, the tube wall is 1mm, and the tube length is 1.5m.

[0016] Straightening equipment is the same as embodiment 1.

[0017] Straightening method: the active chuck drives the metal tube to rotate, the speed is 1100 rpm, and the tensile tension is 1.4KN (for this purpose, the tube reaches the limit of bending. This tension is obtained by testing the same material on a mechanical tensile testing machine), straightening The straight time is 15 seconds.

[0018] Straightening accuracy: The radial runout of the metal pipe after being straightened is less than 0.5 / 1000mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com