Plate stacking straightening method for centre wave buckling of thin-specification high-strength plate

A technology of straightening stacked plates and high-strength plates, which is applied in the field of steel rolling, can solve problems such as large bearing unevenness, shortened service life of bearings, broken bearings, etc., achieve good straightening effect, increase elastic deformation, and improve steel plate quality matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

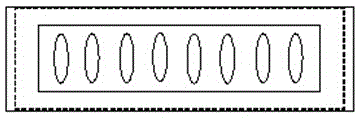

[0017] A cold straightening method with a 6mm yield strength of 1100MPa in the wear-resistant plate, the roll diameter and roll distance of the straightening machine used in the method are 180mm and 240mm respectively. The size of the steel plate is 6×2500×8000mm, the original straightness is about 33mm / 2m, the external dimension of the laminated plate is 5×2500×8000mm, the width of the edge of the laminated plate is 500mm, and the length of the head and tail is 700mm respectively. After the straightening plate and the lining plate are stacked and aligned, the first pass uses 11mm, 1100MPa and 80% plastic deformation rate as the second-level calculation basis, and the calculation obtains that the inlet roll gap is -5mm, the outlet roll gap is 0mm, and the roll gap is 0mm. After the setting is completed, start the first pass of straightening, and remove the mouth-shaped liner after the straightening is completed. The second pass uses 6mm, 1100MPa and 60% plastic deformation rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com