Novel aluminum profile straightening machine

A technology of aluminum profiles and straightening machines, applied in the direction of forming tools, feeding devices, positioning devices, etc., can solve the problems of large force, uneven stress, deformation and other problems of plates, and achieve high work efficiency, high practicability, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

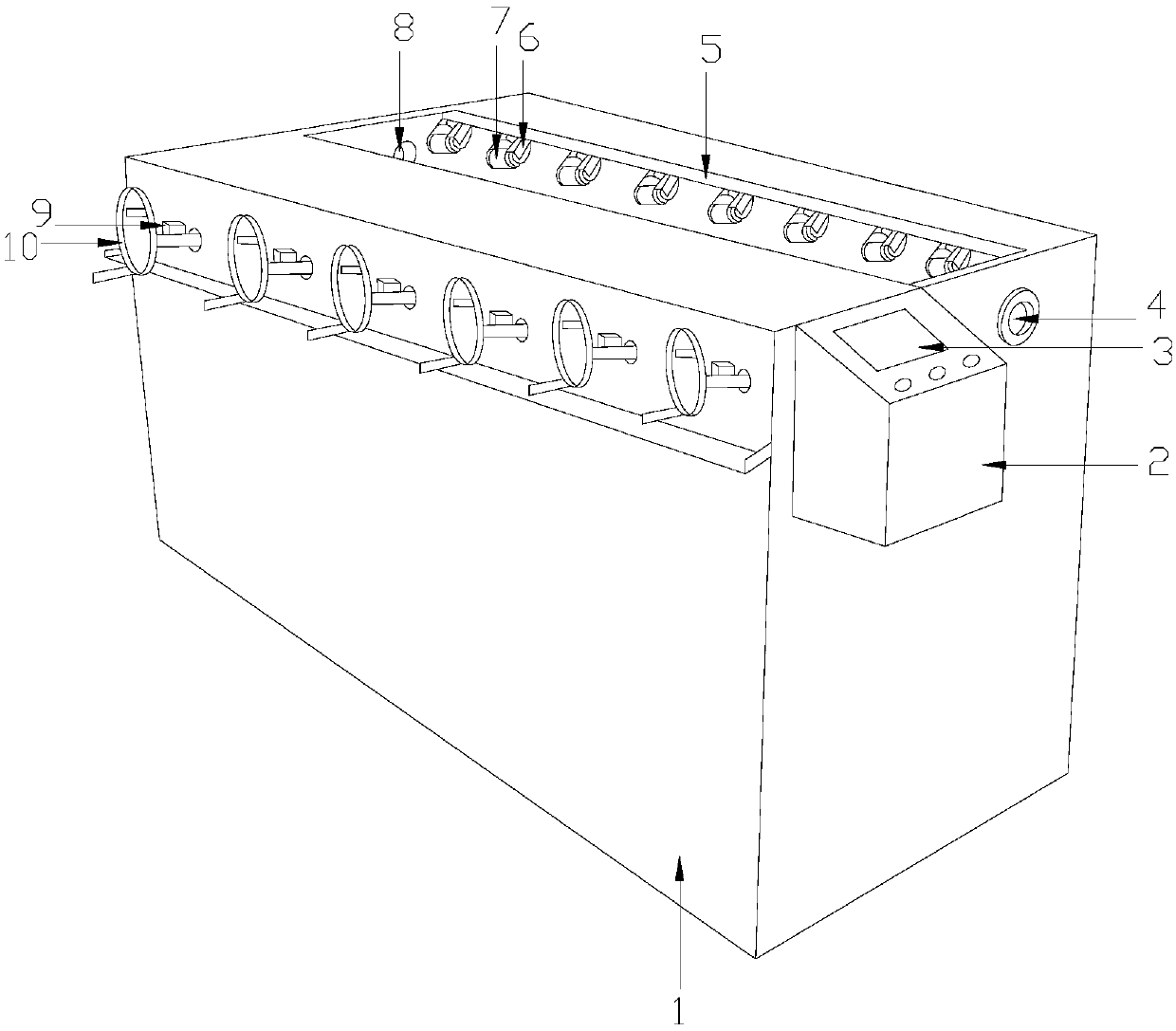

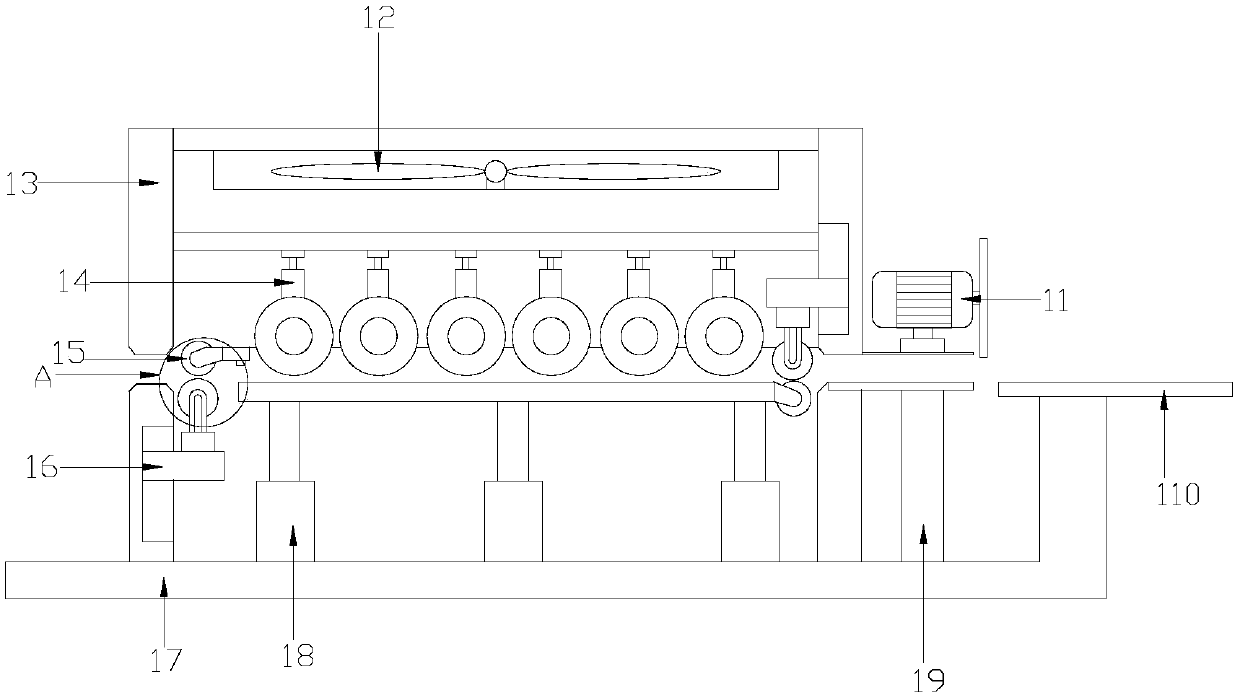

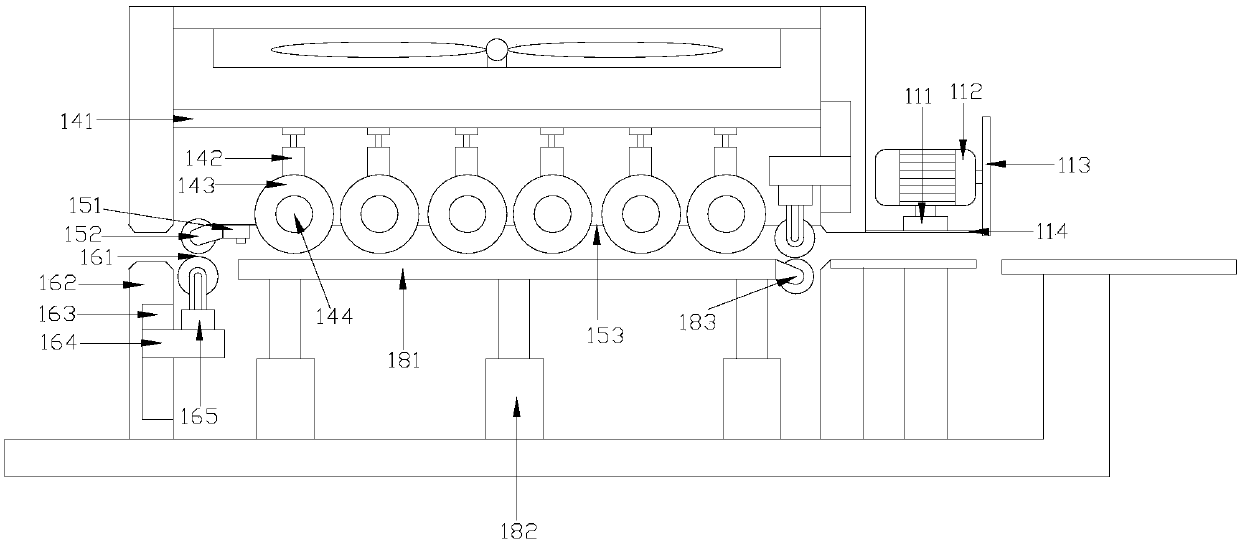

[0021] Such as Figure 1-Figure 5 As shown, the present invention provides a new type of aluminum profile straightening machine, the structure of which includes an automatic straightening mechanism 1, a storage box 2, a control panel 3, a discharge port 4, a fixed shaft 5, a roller seat 6, and a roller 7 , feeding port 8, accuracy meter 9, adjustment wheel 10, the left side of the storage box 2 is fixedly welded to the upper left corner of the right side of the automatic straightening mechanism 1 and is fixedly connected by positioning pins, the rear end of the control panel 3 is fixedly buckled It is combined with the upper end of the storage box 2 and both are integrally formed structures, and the left and right ends of the automatic straightening mechanism 1 are fixedly equipped with a movable device discharge port 4 and a feed port 8, and the three are integrally formed structures, The adjustment wheel 10 is provided with more than two and the rear end is horizontally embe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com