Cutting and bending straightening device for metal pipe

A technology of metal pipe and pipe straighteners, which is applied in other manufacturing equipment/tools, manufacturing tools, etc., to achieve the effect of ensuring performance and smooth cutting surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

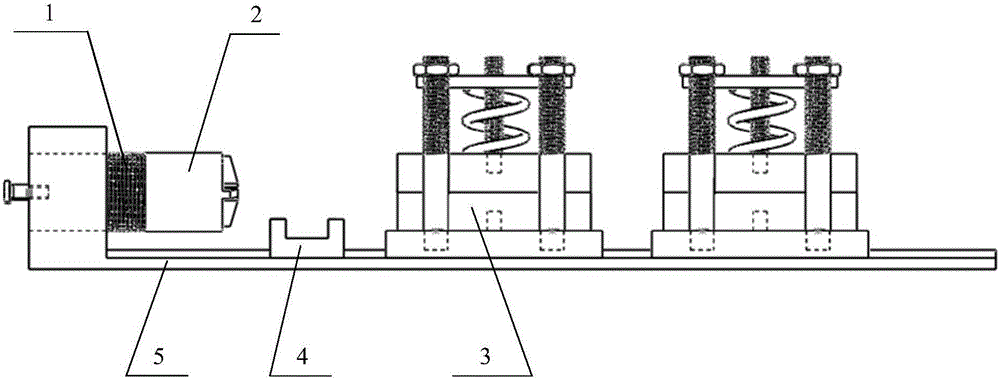

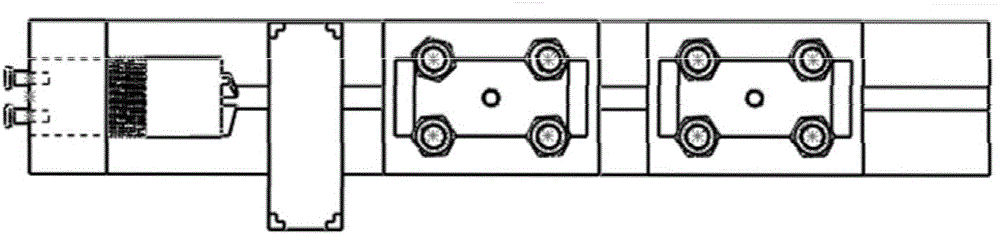

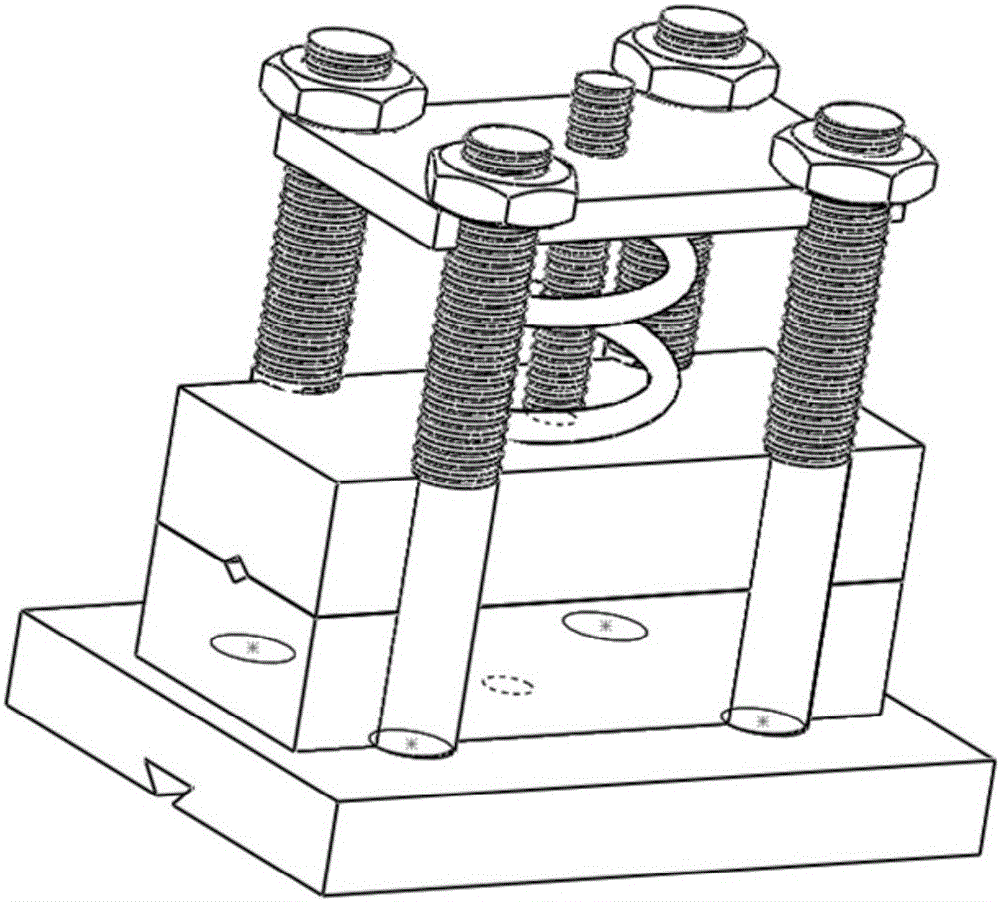

[0032] refer to Figure 1 to Figure 3 , in one embodiment, a metal pipe cutting and bending straightening device, including a mounting base 5, a chuck threaded joint 1, a chuck 2, a metal pipe cutting knife sleeve 4 and a metal pipe straightening device 3, the The seat body at one end of the mounting seat 5 is provided with an internal threaded hole, and the chuck threaded joint 1 is fixedly connected with the chuck 2, and the chuck threaded joint 1 and the chuck 2 have threaded sections and non-threaded joints. The assembly of segments is installed in the internally threaded hole, and the assembly can be adjusted so that its threaded segment or non-threaded segment is in the internally threaded hole, and the metal pipe straightener 3 is opposite to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com