Titanium pipe straightening device

A technology for straightening and titanium tubes, which is applied in the field of titanium tube straightening devices, can solve problems such as poor stability, inconsistent balance points for eliminating stress, and affecting the straightening degree of titanium tubes, so as to achieve the effect of eliminating stress and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

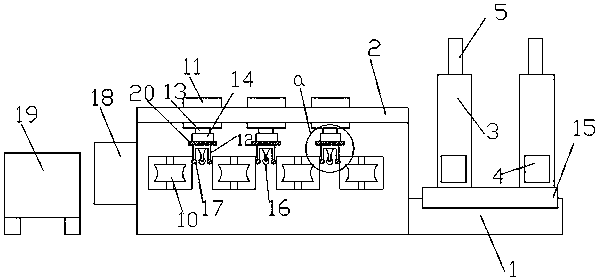

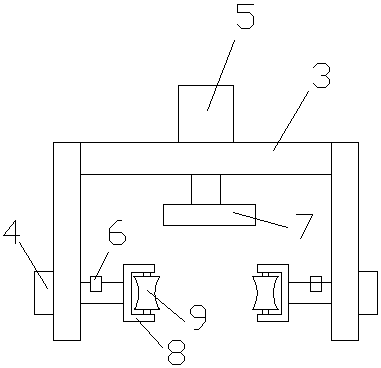

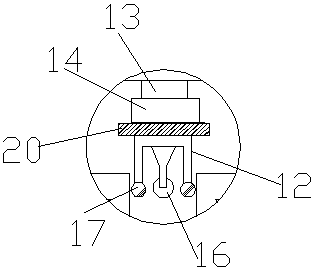

[0014] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

[0015] like figure 1 , 2 Shown in , 3: a kind of titanium pipe straightening device of the present embodiment, comprises feeding conveyor table 1 and straightener 2; The discharge end of described straightener 2 is provided with discharge stabilization box 18, wherein The end of box 18 is connected with detection tooling 19.

[0016] Wherein said feeding and conveying platform 1 is provided with several portal frames 3 in turn; each portal frame 3 is fixed on a lifting platform 15 .

[0017] The left and right ends of each door frame 3 are provided with a first cylinder 4 and the top is connected and fixed with a hydraulic cylinder 5, wherein the infrared sensor 6 is fixed on the first cylinder 4, and the hydraulic shaft of the hydraulic cylinder 5 is connected with the hydraulic cylinder 5. The upper auxiliary roller 7 is connected and fixed; the cylinder sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com