Hot-straightening process for thin-gauge coiling rolling plate

A thermal straightening and thin-gauge technology, which is applied in the field of steel rolling, can solve problems such as the inability to set the roll gap, and achieve the effect of improving the qualified rate of thermal straightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

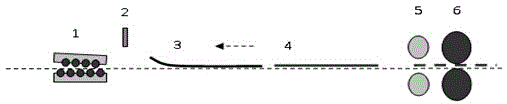

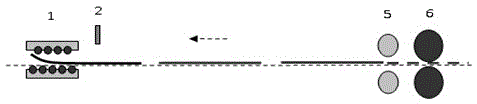

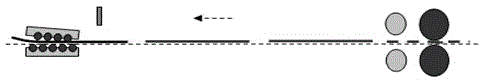

[0021] A thermal straightening process for rolled sheet with 5mm yield strength and 350MPa head warp. The roll diameter and roll distance of the leveler used in this process are 215mm and 230mm respectively, and the maximum inclination of the roll box is 8mm. The rolled piece cannot normally bite into the leveler due to the warping of the head. The total length of the rolled piece is about 200m, and the distance from the leveler to the rolling mill is 135m. Straightening and steel throwing form a linkage. The process requires that the entrance roll gap of the straightener is 0mm, and the exit roll gap is 5mm. Quickly lift the roll gap to make the warped plate pass through the straightening machine smoothly, and track the position of the steel plate head through the thermal inspection before the machine through the first stage. After the steel plate head passes through the straightener, the first stage automatically sets the roll gap and completes. Straighten.

[0022] The sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com