Vibrating micromechanical sensor of angular velocity

a micromechanical sensor and vibration technology, applied in the direction of acceleration measurement using interia force, turn-sensitive devices, instruments, etc., can solve the problems of limiting the dynamic of the signal, and reducing the accuracy of the signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

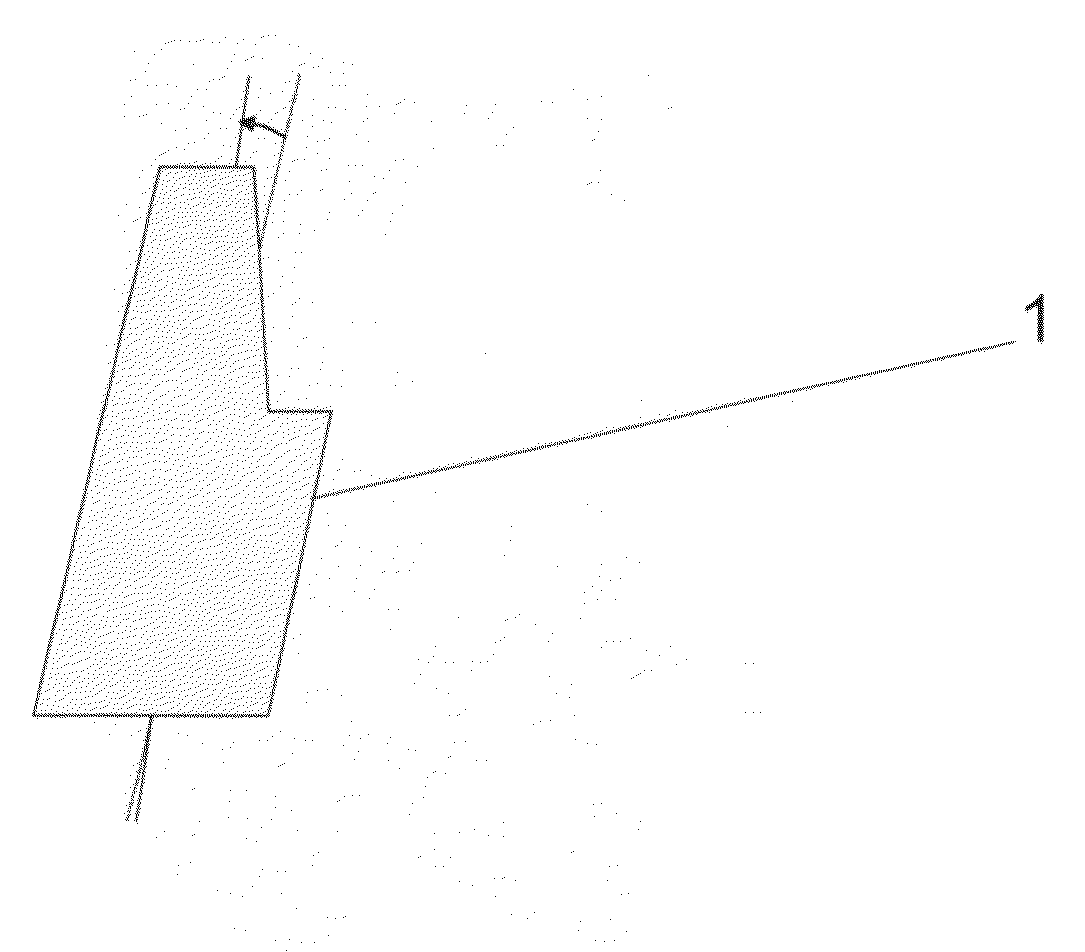

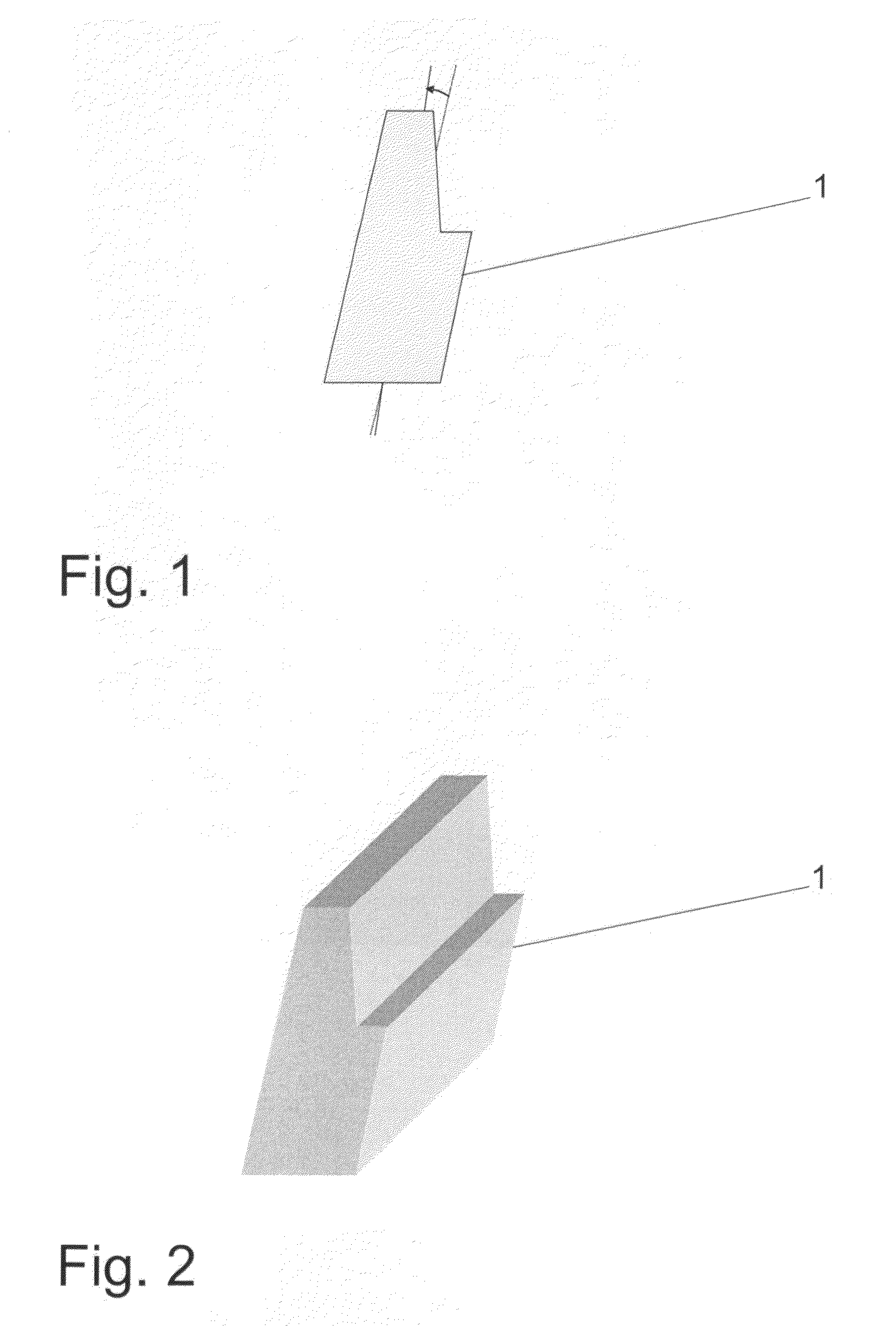

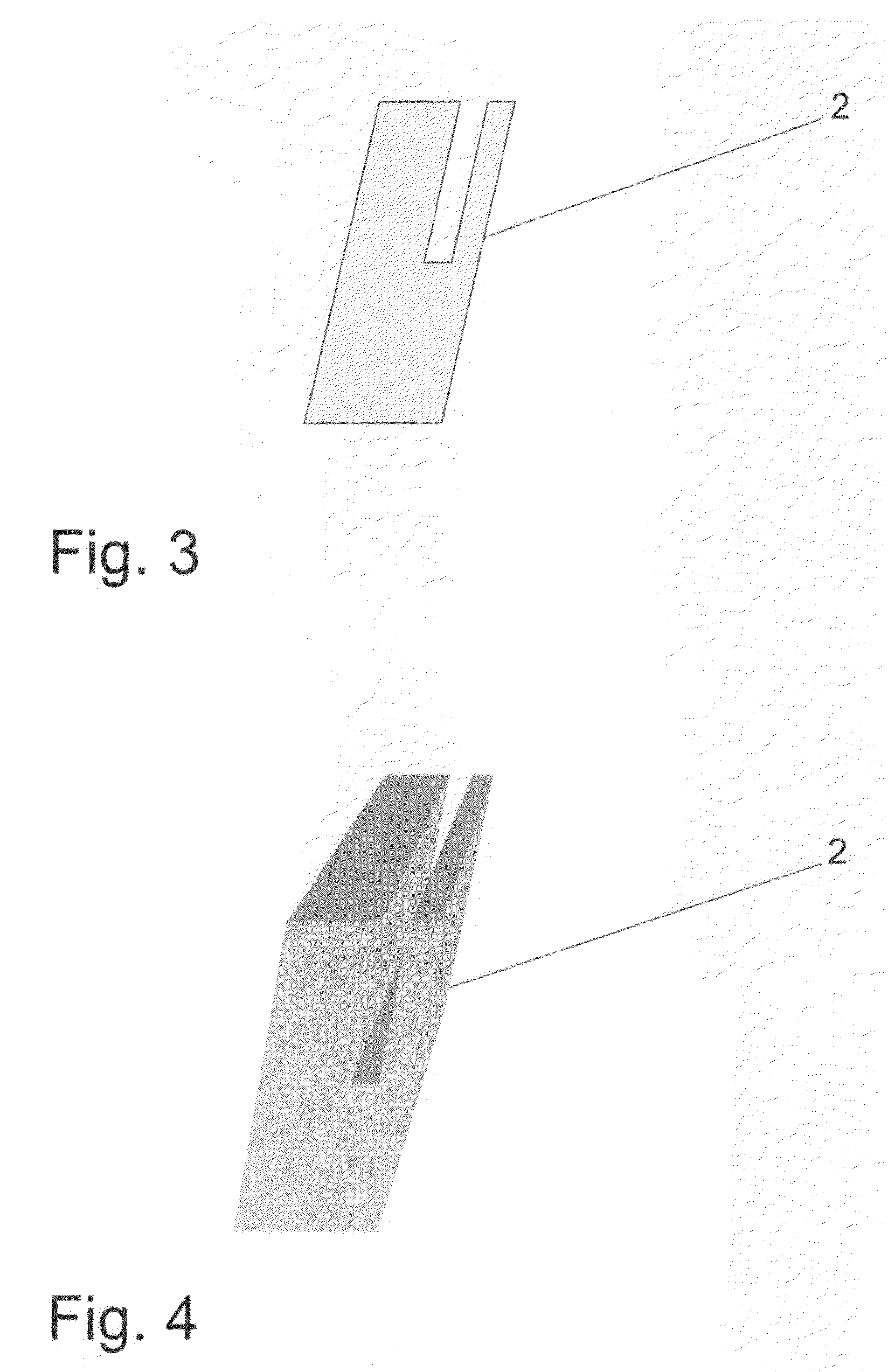

[0030]In a vibrating sensor of angular velocity according to the invention, the primary motion to be activated is the vibration of at least one seismic mass and an associated moving electrode. In addition to the primary motion, the seismic mass possesses another degree of freedom in relation to a detection axis essentially perpendicular to the primary motion.

[0031]Further, the sensor of angular velocity according to the invention comprises a seismic mass and an associated moving electrode, which mass is supported to the frame of the sensor component by means of a spring structure.

[0032]The moving electrode in the primary motion mode of the vibrating sensor of angular velocity according to the invention is activated into vibration. Thus, the coupling caused by the Coriolis force activates the detection motion mode. The motion axes of the primary motion mode and the detection motion mode, or the detection motion modes, are essentially perpendicular to each other. Due to the known non-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Angular velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com