Fixing device for transformer outlet copper bar and fixing method thereof

A technology for fixing devices and transformers, which is used in transformer/inductor components, transformer/inductor cooling, inductor/transformer/magnet manufacturing, etc. To the buffer effect and other issues, to achieve the effect of easy distribution and improved connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

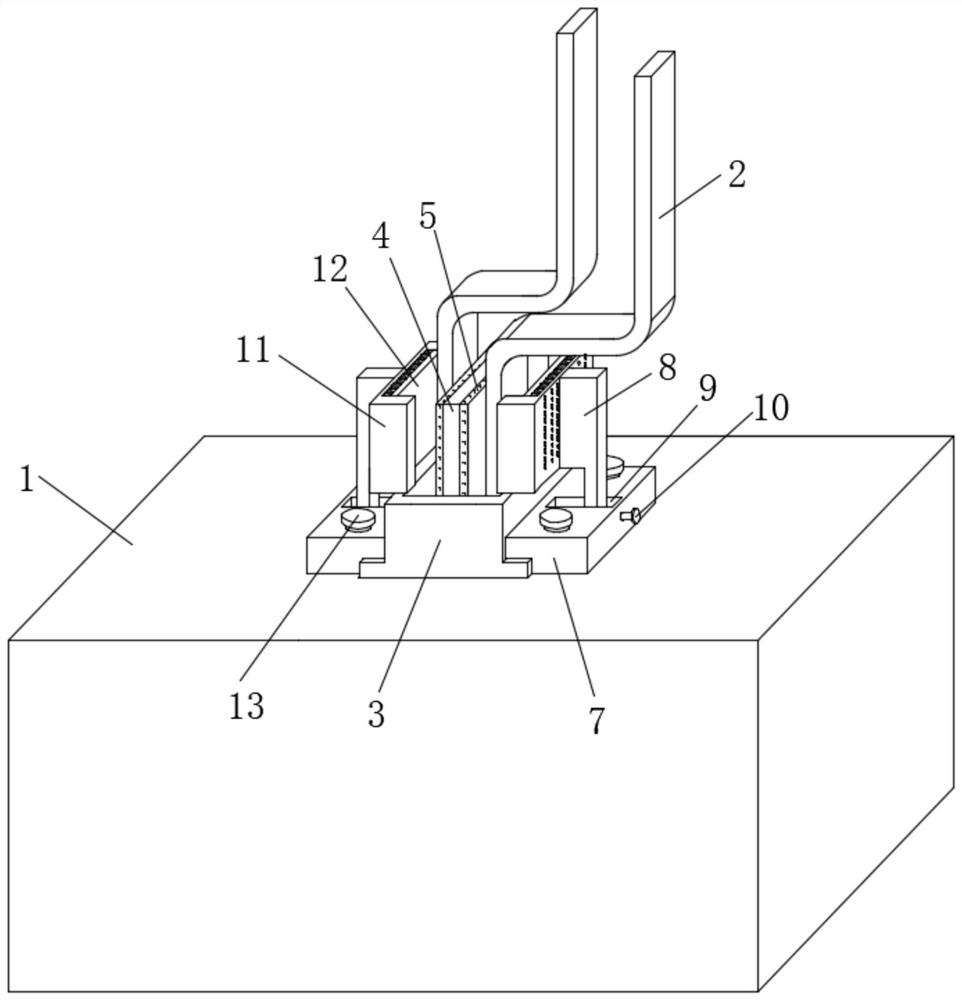

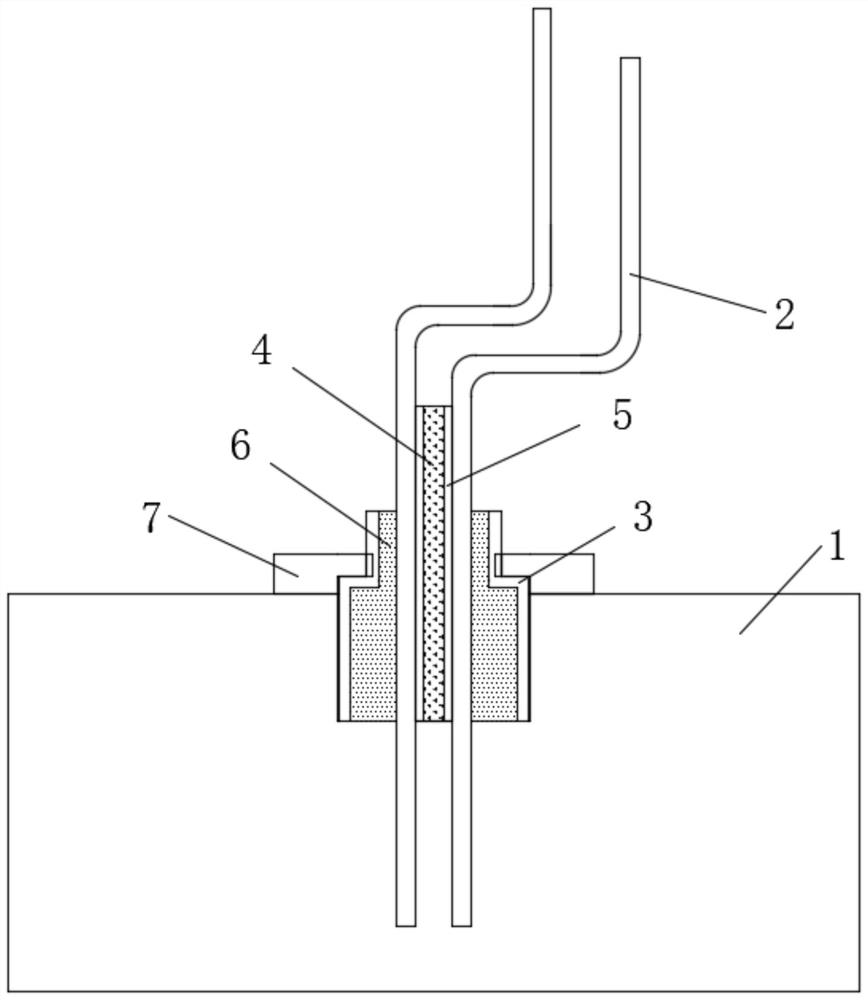

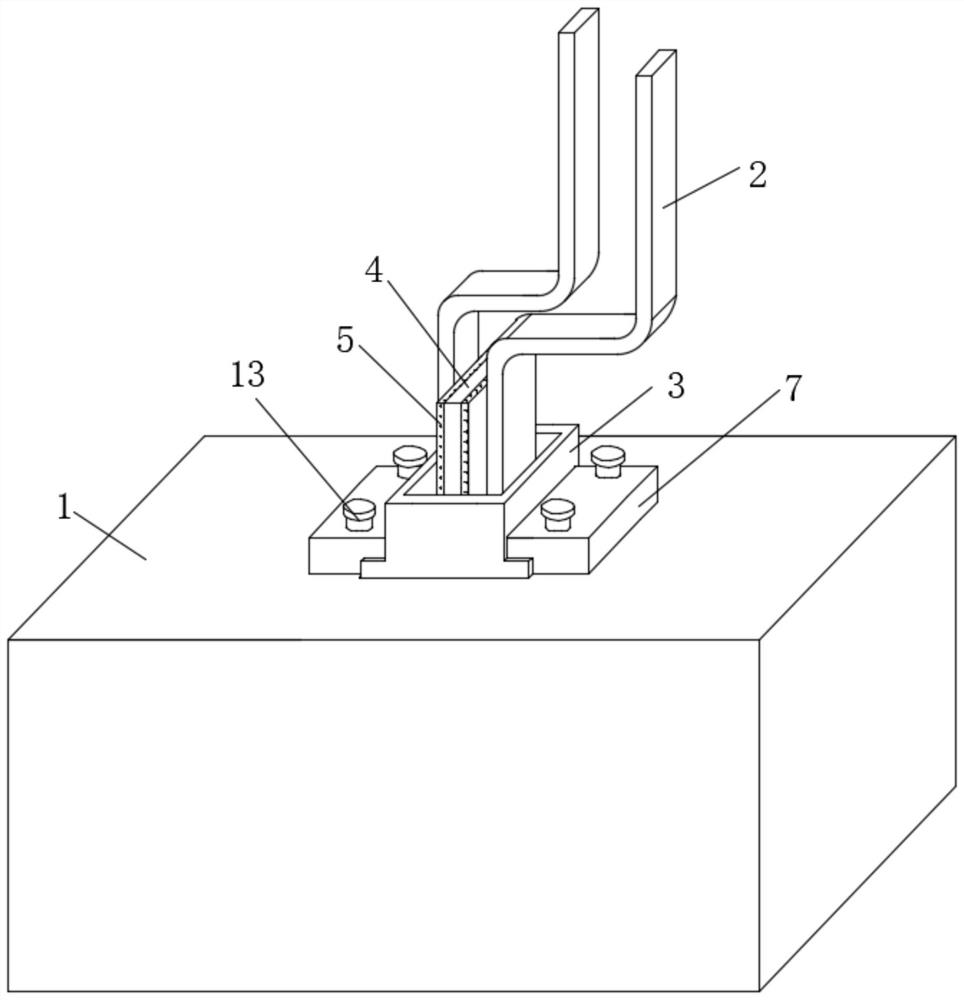

[0042] see Figure 1-2 , a fixing device for a transformer lead-out copper bar, including a convex mounting plate 3 for fixing two copper bar bodies 2 to an outlet template 1, and the convex fixing plate 3 is embedded in the outlet template 1, The inside of the convex mounting plate 3 is provided with a fixed cavity for fixing the copper bar body 2. The middle of the fixed cavity is fixedly connected with an insulating partition 4, and the two copper bar bodies 2 are located on both sides of the insulating partition 4. Both sides of the insulating partition 4 are provided with a buffer layer 5 against the inner side walls of the two copper bar bodies 2, and the cooperation of the insulating partition 4 and the convex mounting plate 3 not only realizes the limit of the two copper bar bodies 1 Position fixation, also plays an insulating role between the two copper bar bodies, and the buffer layer 5 on the two outer walls of the insulating partition 4 plays a buffering role on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com