Metal film double-sided printing device

A double-sided printing, metal film technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of low printing quality and difficult double-sided printing, and achieve the effect of high printing quality and difficult position shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

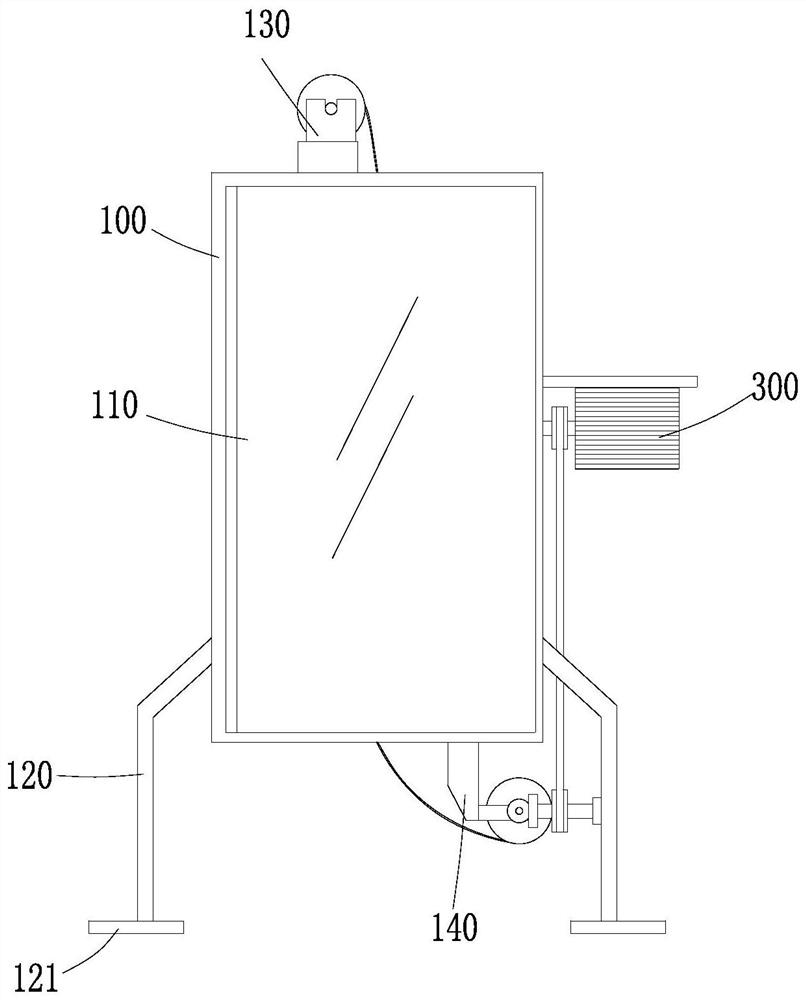

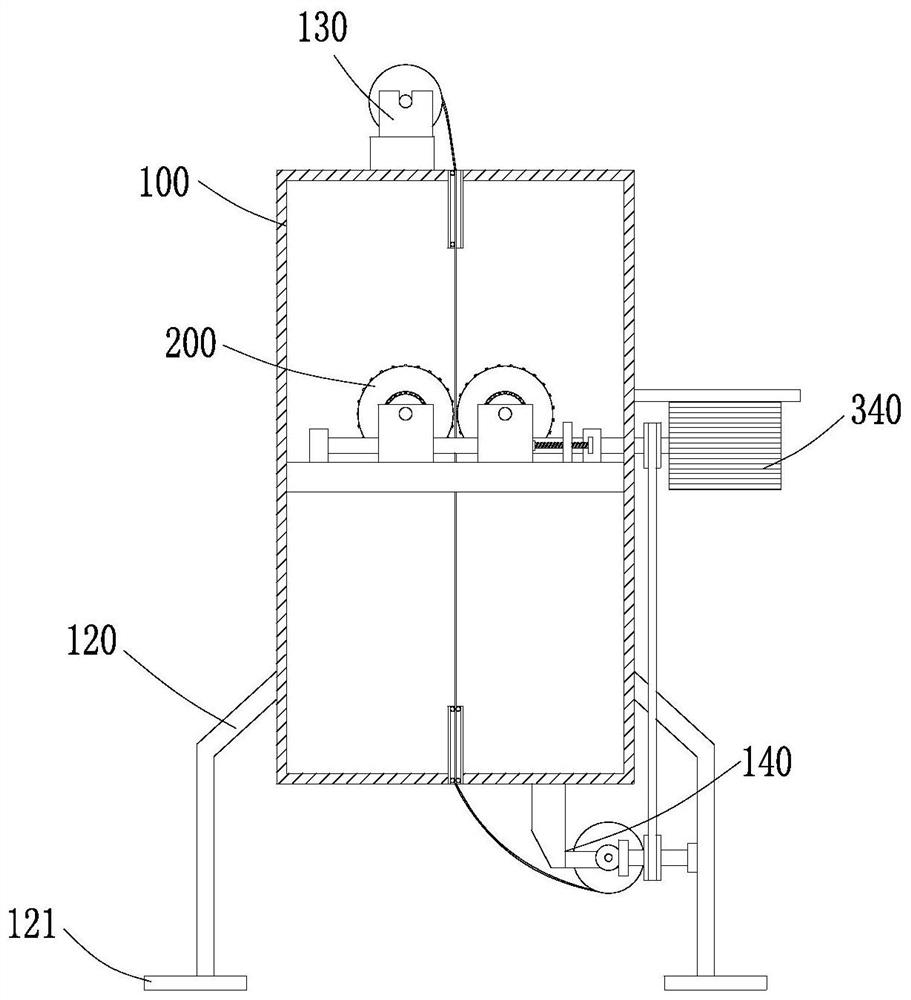

[0041] The present invention provides a technical solution: a metal thin film double-sided printing device, comprising: 100 in the figure of the shell, an opening is arranged on the front side of the figure: 100 in the figure of the shell, a first fixing frame 130 at the upper end of 100 in the figure of the shell, It is used to place the film raw material cylinder 131. In the figure of the shell: the lower end of 100 is provided with a second fixing frame 140, which is used to place the film winding cylinder 141;

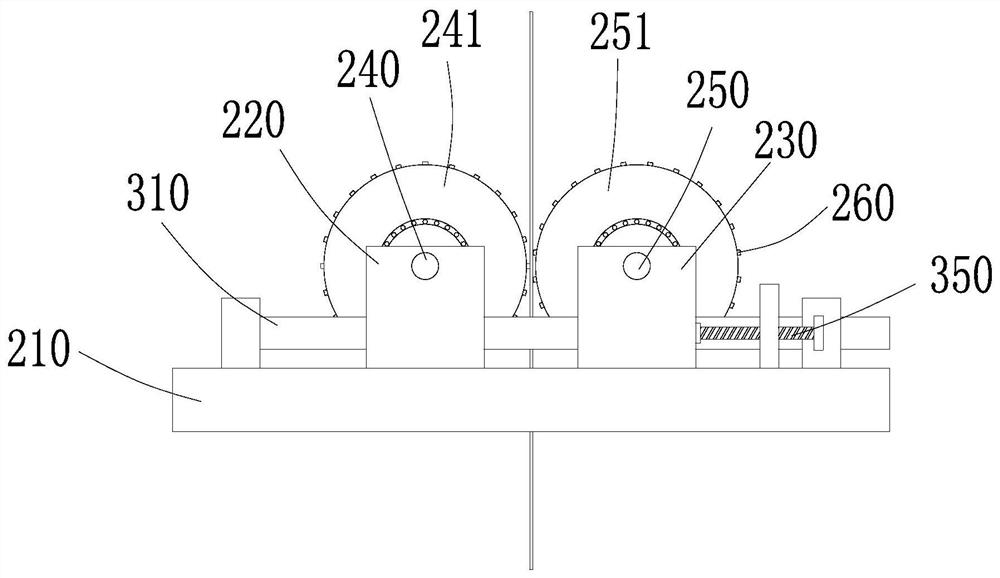

[0042] The printing mechanism 200, the printing mechanism 200 is arranged inside the casing diagram: 100, and is used for double-sided printing on the film raw material; the printing mechanism 200 includes the horizontal support plate 210, the horizontal support plate arranged inside the casing diagram: 100 210 is provided with a first vertical board 220 and a second vertical board 230, the first vertical board 220 is provided with a second rotating rod 240, the sec...

Embodiment 2

[0045] On the basis of Embodiment 1, in the figure of the housing: the bottom of 100 is provided with supporting legs 120, and the supporting legs 120 are fixed to the ground through connecting plates 354;

[0046] One side of the first fixing frame 130 is provided with a feeding pipe 132, and the feeding pipe 132 extends vertically into the housing figure: 100, and is used to introduce the film raw material into the housing figure: 100 for printing, and the second fixing A discharge pipe 142 is arranged on one side of the frame 140, and the discharge pipe 142 extends vertically to the inside of: 100 in the housing figure, and is used to export the printed film to the film reel 141;

[0047] Both the top and the bottom of the feed pipe 132 and the discharge pipe 142 are rotatably mounted with guide rollers 150 .

[0048] Concretely, the metal film enters the shell through the feed pipe 132: 100 in the figure, the feed pipe 142 leads out of the shell: 100, the feed pipe 132 and...

Embodiment 3

[0050] On the basis of Embodiment 1 or Embodiment 2, the driving mechanism 300 includes a first rotating rod 310 on the transverse support plate 210, and a driving source 340 arranged on the outer wall of 100 in the housing diagram, and the driving source 340 outputs The shaft is drivingly connected to the first rotating rod 310, the first rotating rod 310 is provided with a first worm segment 320 and a second worm segment 330 at intervals, the second rotating rod 240 is fixedly connected with the first rotating wheel 270, the third The second rotating wheel 280 is fixedly connected to the rotating rod 250, and the outer walls of the first rotating wheel 270 and the second rotating wheel 280 are all provided with several groups of pins 290, and the first rotating wheel 270 is connected with the first worm section by several groups of pins 290. 320 are meshed, and the second rotating wheel 280 is meshed with the second worm segment 330 through several sets of pins 290;

[0051]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com