A clamp screw riveting device

A riveting device and screw technology, which is applied in the field of clamp screw riveting devices, can solve the problems of high labor intensity, inability to meet the needs of large-scale production, and low efficiency of manual work, so as to improve work efficiency, save manpower, Effect of improving transmission stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

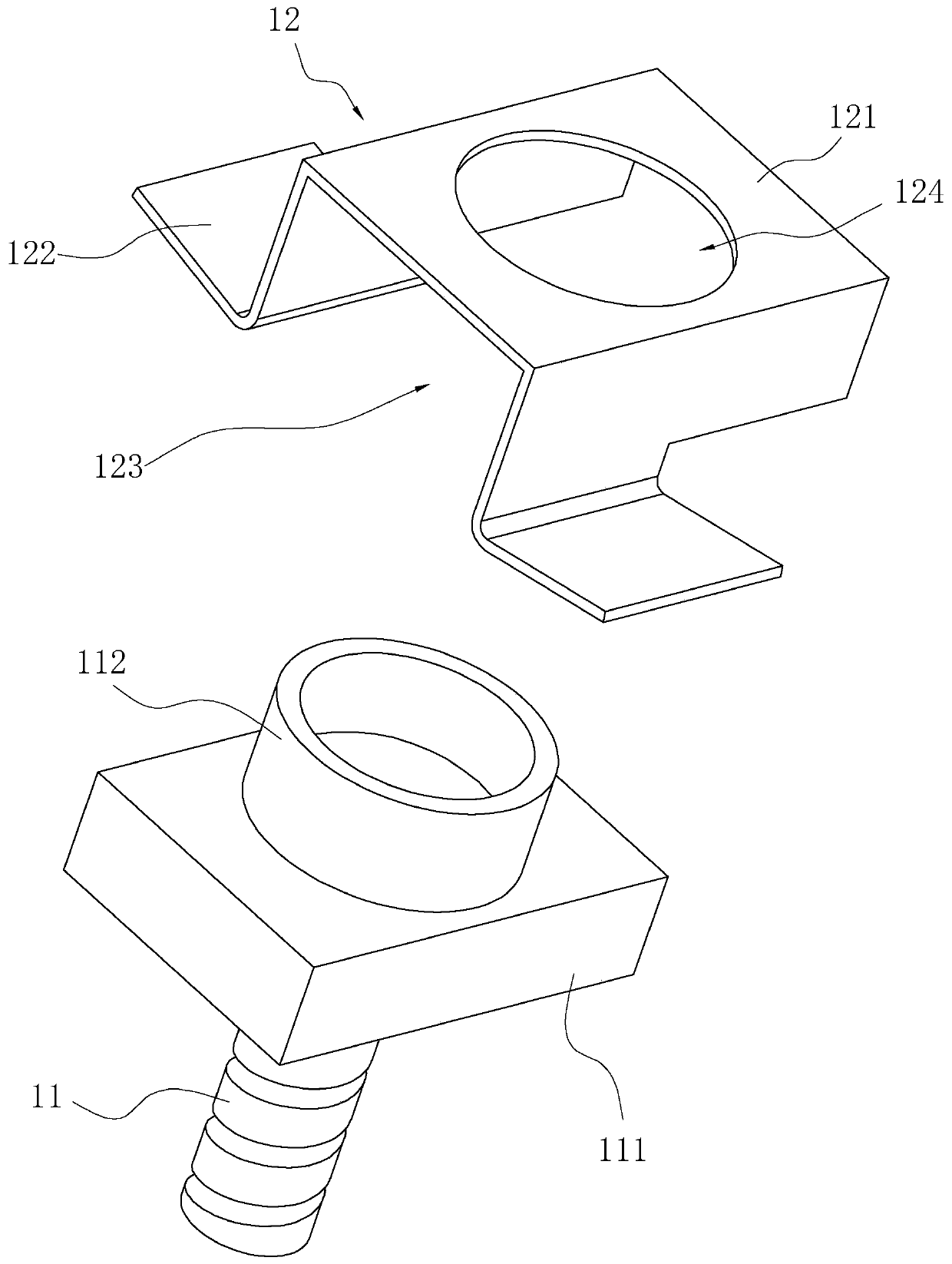

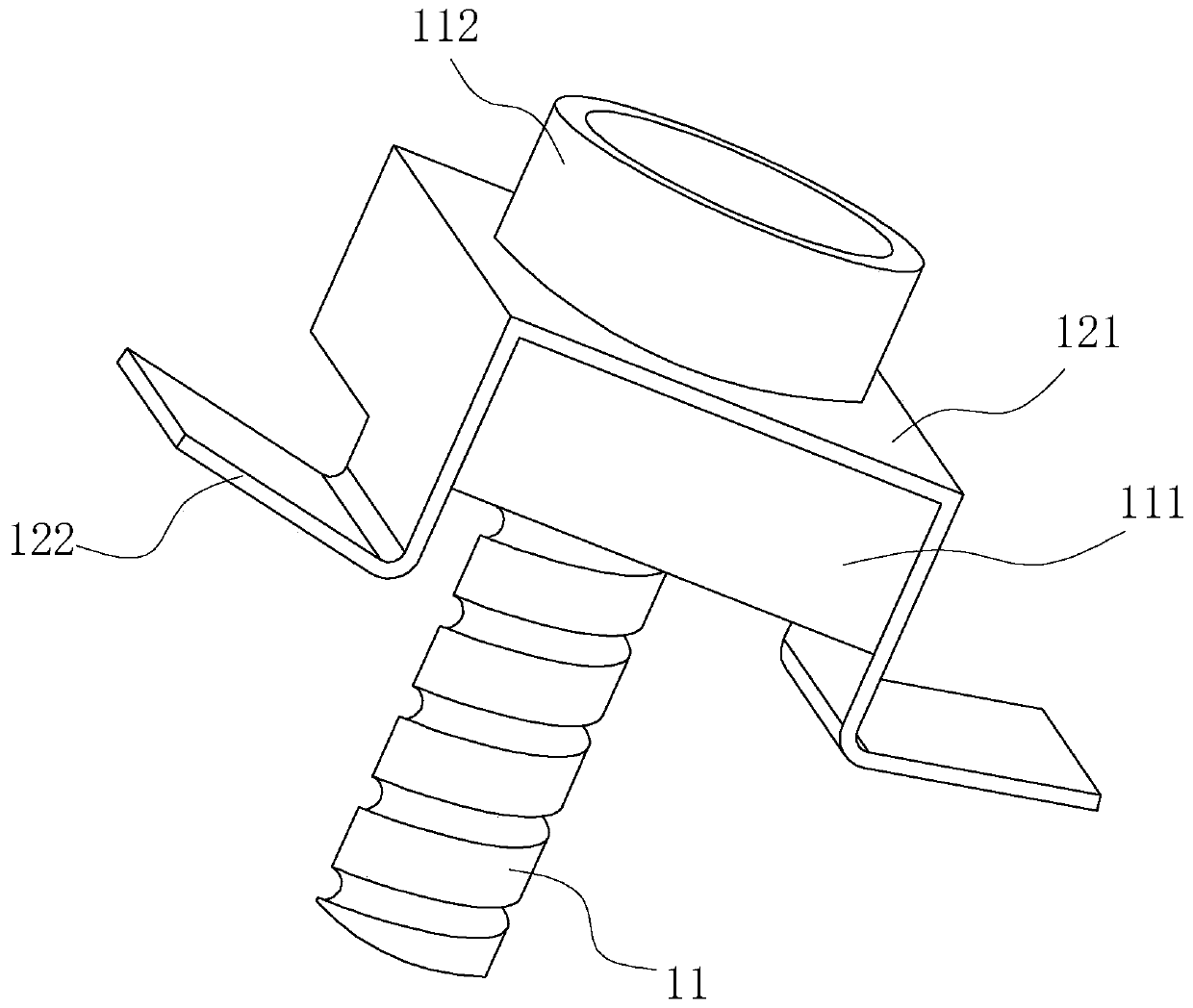

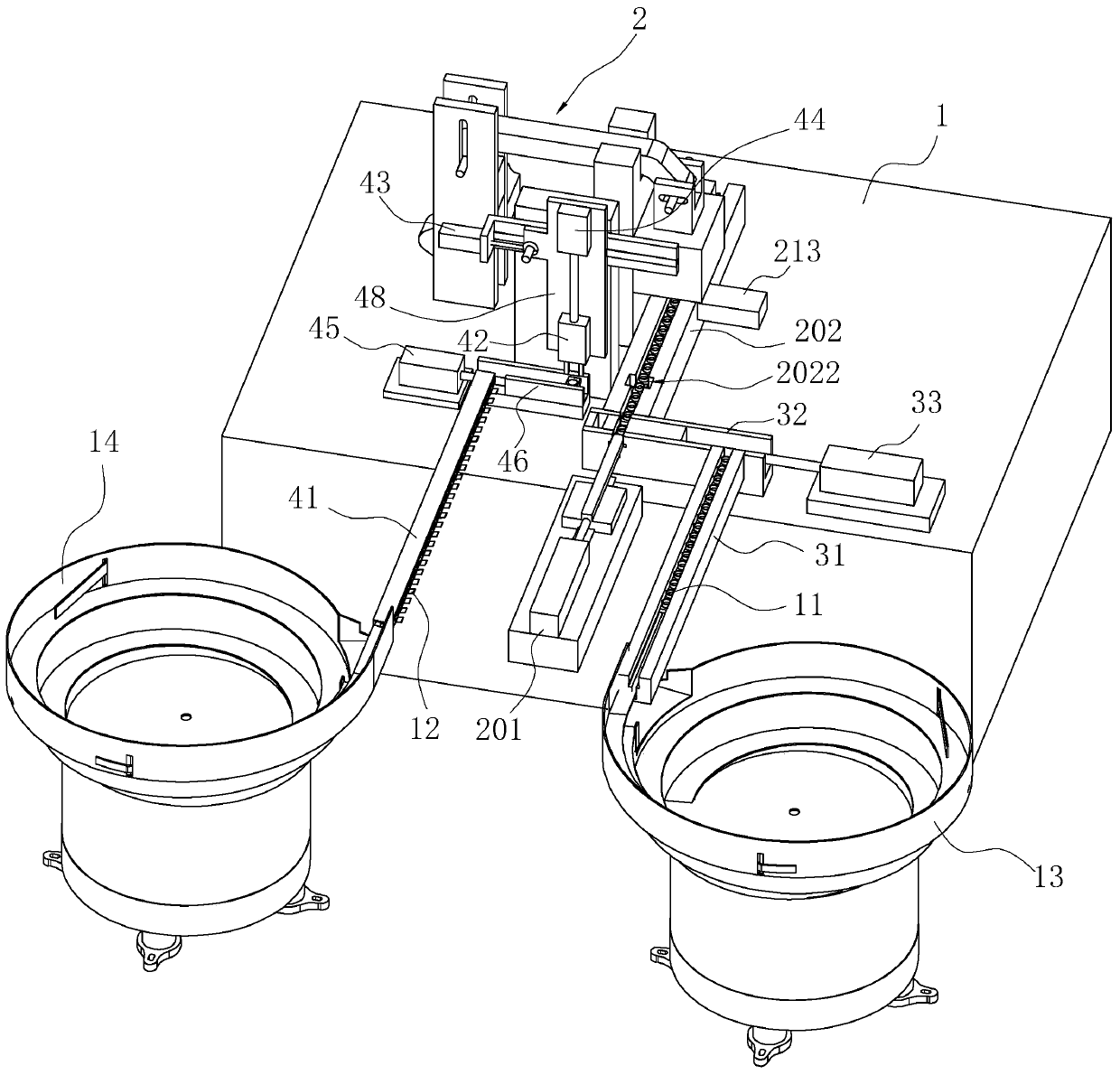

[0041] A clamp screw riveting device, such as image 3 with Figure 4 As shown, it includes a frame 1, a pressing mechanism 2, a screw vibrating plate 13, a screw conveying mechanism, a gasket vibrating plate 14 and a gasket conveying mechanism. The pressing mechanism 2 is arranged on the frame 1, which includes a general conveying track 202 for the confluence of the screw 11 and the gasket 12, a first cylinder 201 for pushing the screw gasket assembly, and a first cylinder 201 for pressing the gasket 12. Riveted assembly with screw 11. The total conveying track 202 has a first conveying groove 2021 whose cross section matches the cross section of the screw washer assembly.

[0042] Such as image 3 with Figure 5 As shown, the screw conveying mechanism is arranged on the frame 1, and is used to convey the screws 11 output from the screw vibrating plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com