smt patch technology and conveying device applied to it

A technology of conveying device and conveyor belt, which is applied in the direction of conveyor, transportation and packaging, etc. It can solve the problems of PCB board inclination, position offset, affecting the quality of patch, etc., and achieve the effect of convenient and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

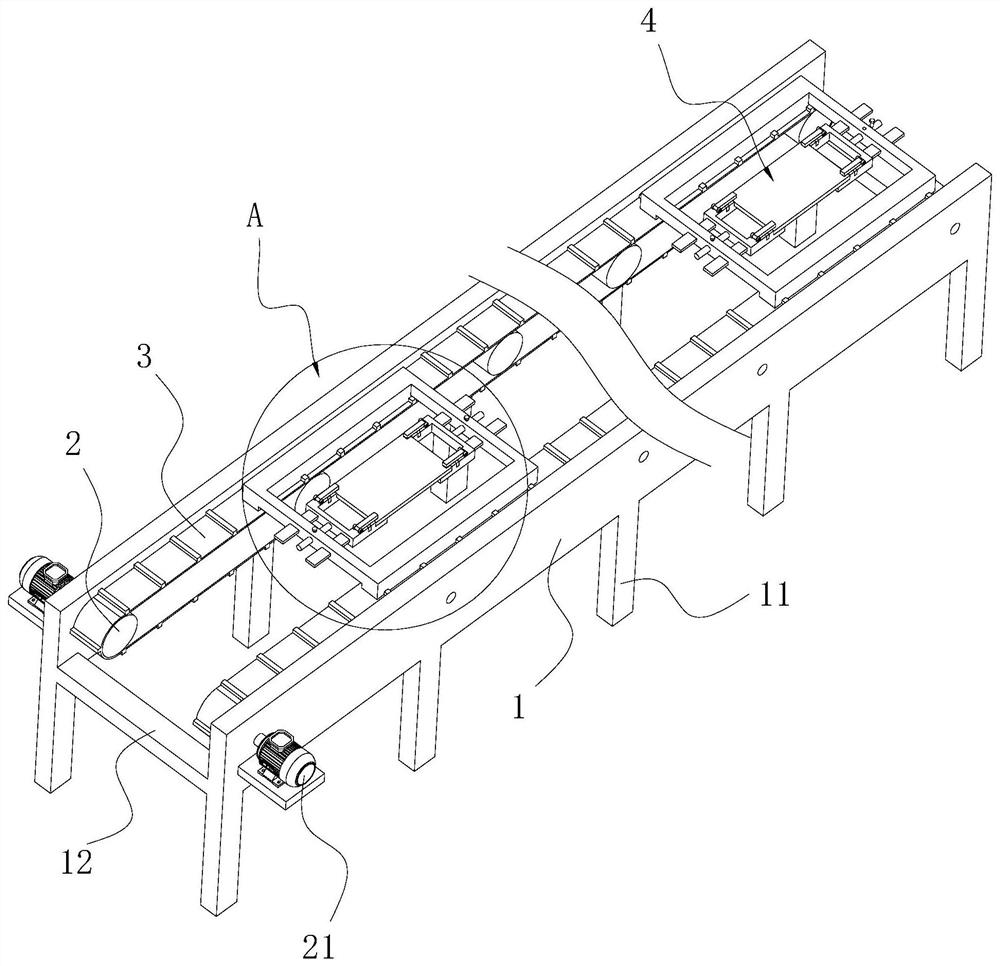

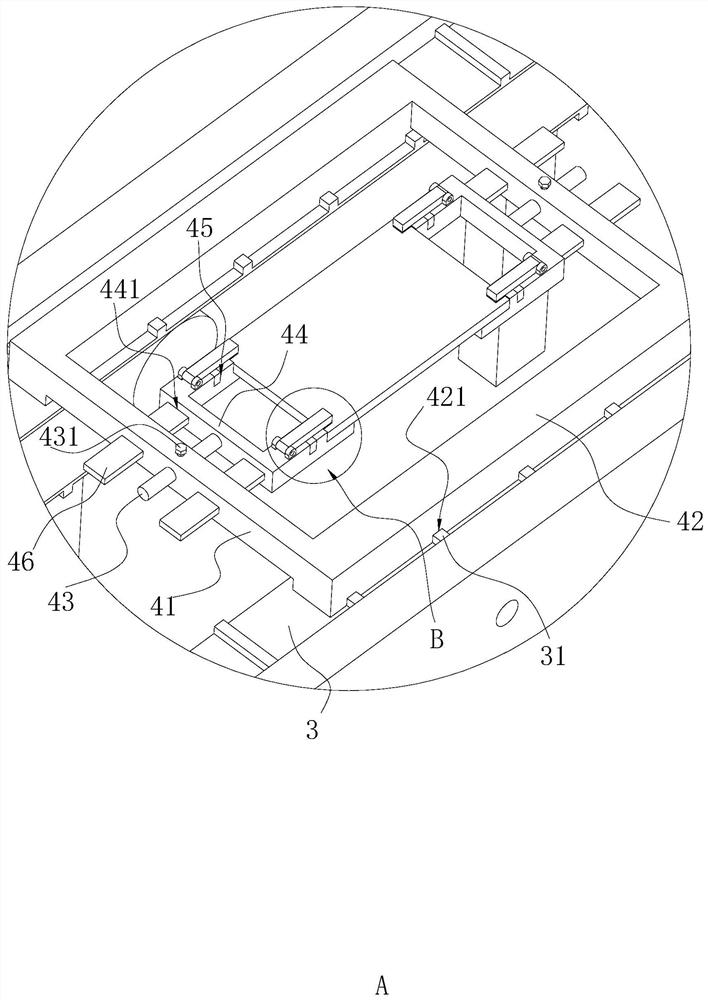

[0038] Embodiment one: a kind of conveying device, see attached figure 1 , including two vertically arranged vertical boards 1 parallel to each other, support legs 11 fixedly connected to the bottoms of both ends of the two vertical boards 1, a number of rotating rollers 2 rotatably connected to one side of the vertical boards 1 close to each other, fixedly connected to the vertical boards 1 is used to drive the motor 21 of one of the rotating rollers 2 to rotate, the conveyor belt 3 sleeved on the rotating roller 2 and the clamping mechanism 4 supported on the two conveyor belts 3; the length directions of the two vertical plates 1 are parallel to each other and the length The direction is set horizontally, the axes of several rotating rollers 2 are perpendicular to the riser 1 and the axes of several rotating rollers 2 are located in the same horizontal plane, and the top surface of the conveyor belt 3 is set horizontally; the PCB board is clamped in the clamping mechanism 4,...

Embodiment 2

[0044] Embodiment two: a kind of SMT patch technology, comprises the following steps:

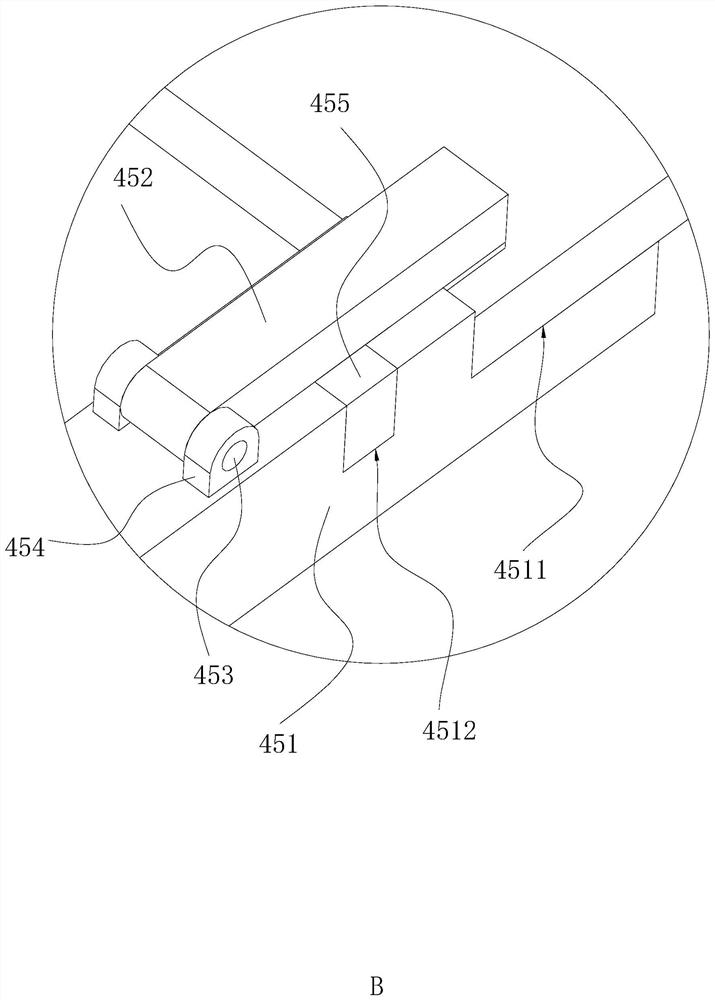

[0045] a. Fixing the PCB board: Insert the two sides of the PCB board into the accommodation grooves 4511 of the four bottom plates 451 respectively, then turn over the pressure plate 452, under the action of the magnetic block 455, the pressure plate 452 fixes the PCB board, and then rotate and connect Rod 43, so that the PCB board is in a horizontal position, insert the positioning plate 46 into the positioning groove 441, and then tighten the fastening bolt 431;

[0046] b. Install the clamping mechanism 4: support the connecting plate 42 on one end of the conveyor belt 3, and insert the positioning protrusion 31 into the corresponding positioning groove 421;

[0047] c. Glue dispensing: The conveyor belt 3 drives the clamping mechanism 4 forward, and the PCB board is transported to the bottom of the glue dispenser. Under the action of the glue dispenser, the glue is printed on the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com