Stainless steel water heating joint and production process thereof

A production process, stainless steel technology, applied in the direction of pipes/pipe joints/fittings, threaded connections, passing components, etc., can solve the problems of high production cost, complex processing process, complex process, etc., and achieve the overall structure of ingenious settings and flexible welding process. , the effect of simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings. For the convenience of explanation, the following "left" and "right" are all related to the attached figure 1 Same direction as shown.

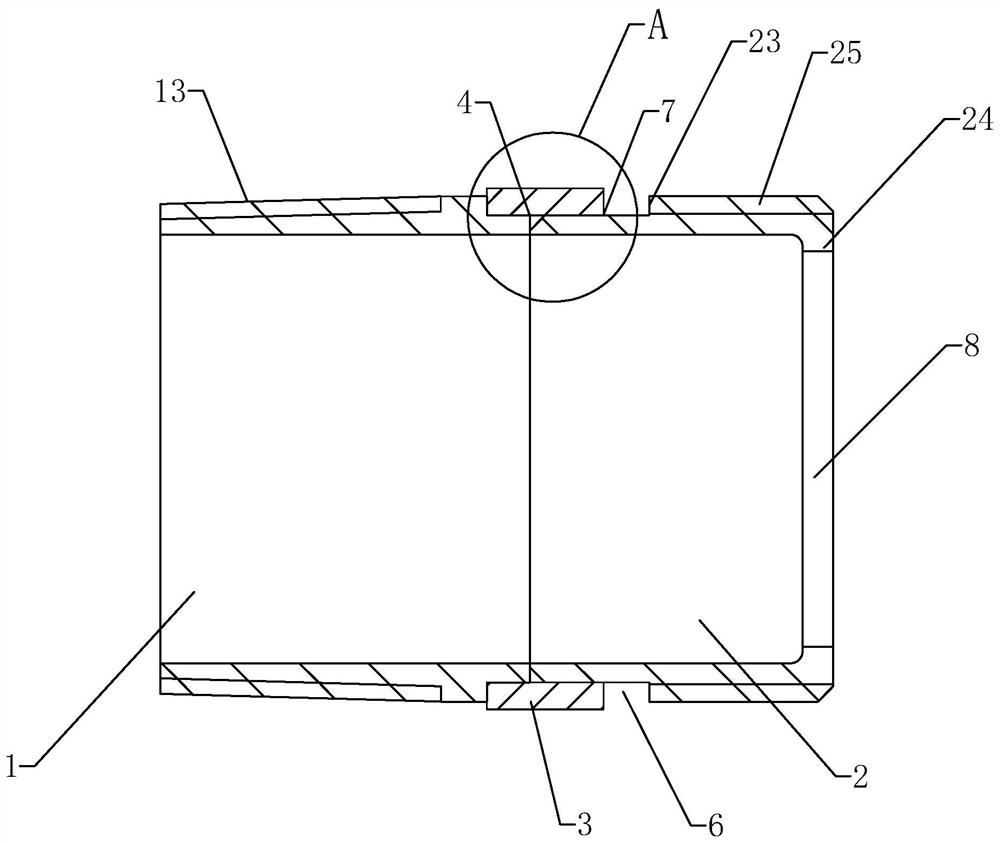

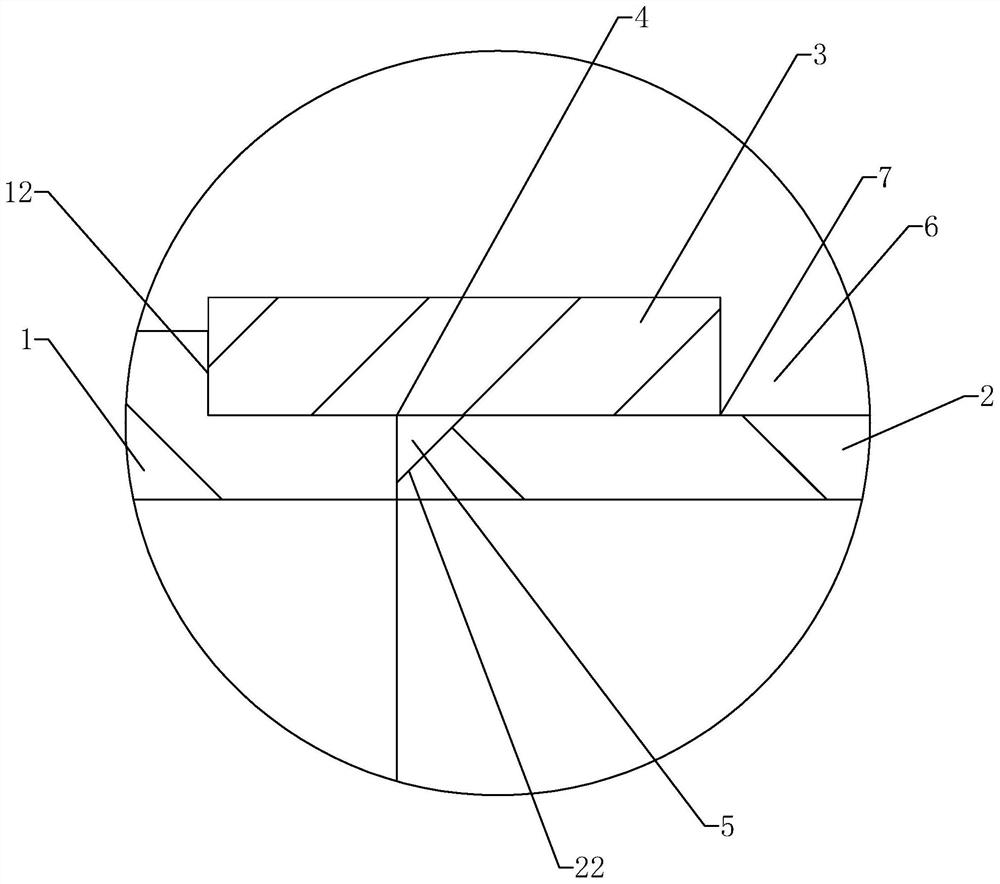

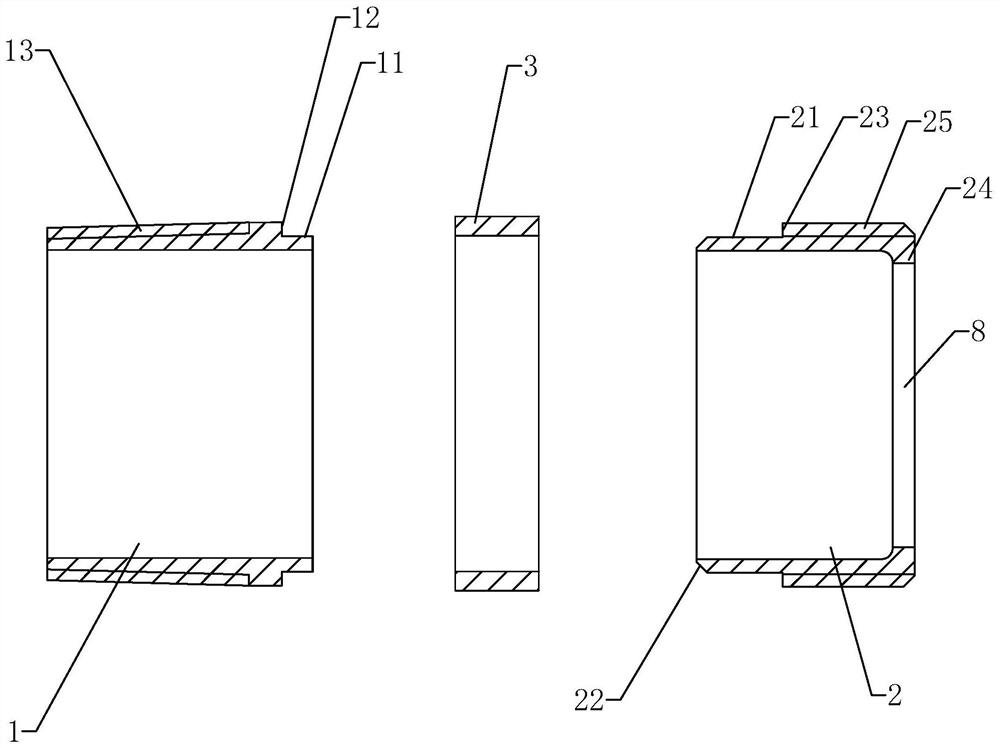

[0038] A stainless steel plumbing joint and its production process, a stainless steel plumbing joint, such as Figure 1-3As shown, it is a schematic diagram of the structural relationship of the plumbing joint, including a first connecting sleeve 1, a second connecting sleeve 2 and an outer hexagonal hexagonal sleeve 3 arranged coaxially, the first connecting sleeve 1 and the second connecting sleeve 2 One-to-one correspondence is inserted at both ends of the hexagonal sleeve 3, the inner diameter of the first connecting sleeve 1 and the second connecting sleeve 2 are the same, the outer wall of the first connecting sleeve 1 is provided with a first annular notch 11, the first annular groove The mouth 11 is opened axially fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com