Workpiece multi-stage positioning device applied to numerical control milling machine

A technology of CNC milling machine and positioning device, which is applied in the direction of positioning device, metal processing machinery parts, manufacturing tools, etc., which can solve the problems of low processing efficiency, easy shifting position of workpiece, repetitive operator burden, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

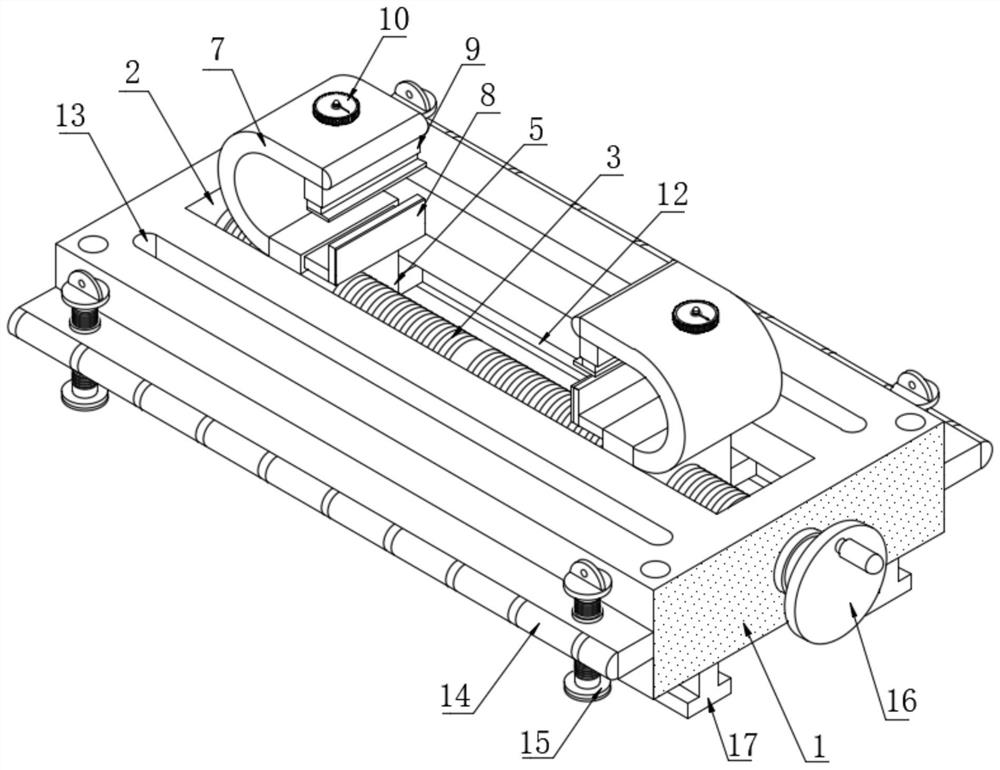

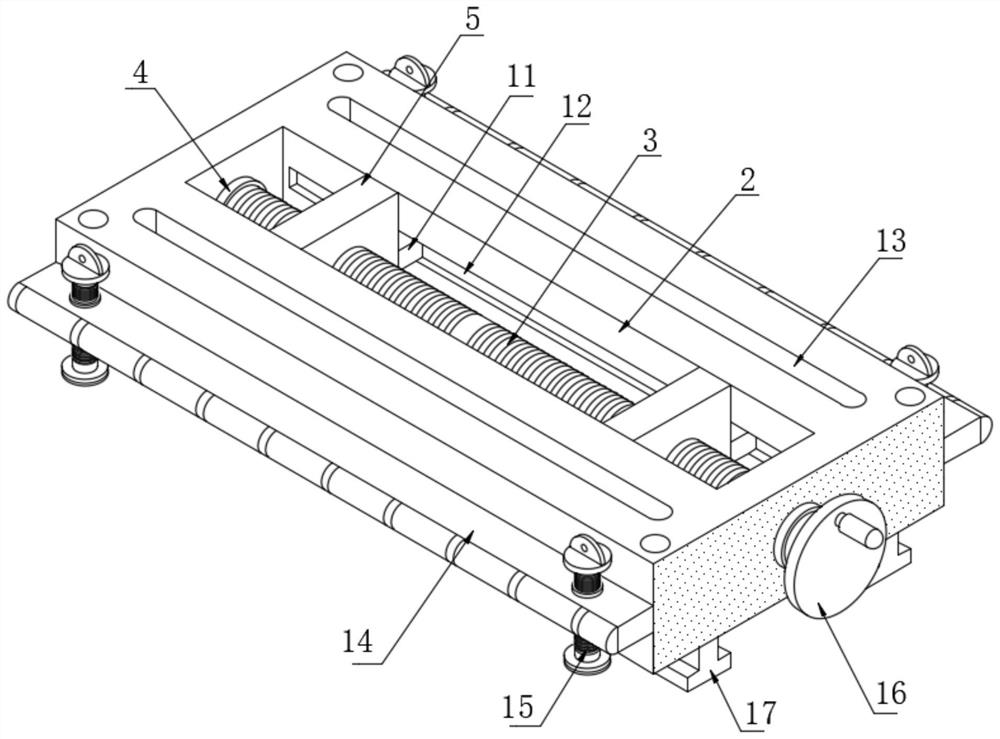

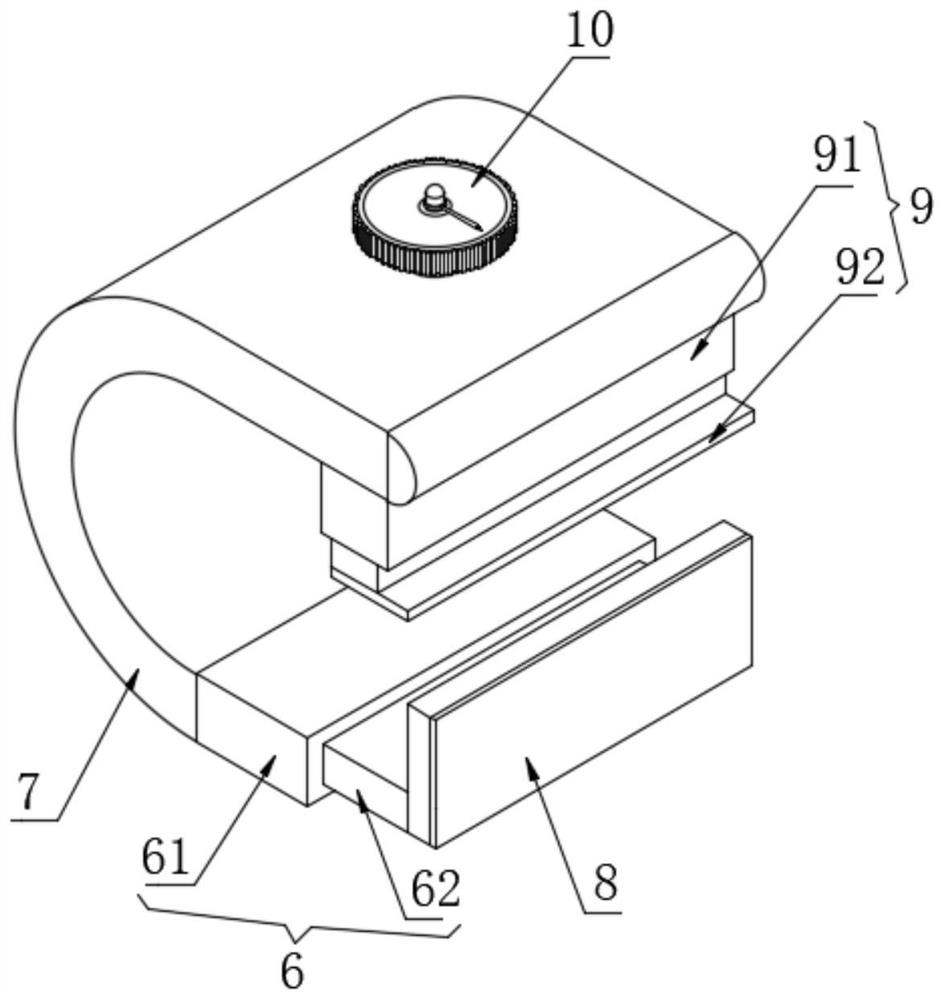

[0027] Such as Figure 1-5 As shown, the present invention provides a technical solution: a workpiece multi-stage positioning device applied to a CNC milling machine, comprising a base 1, the upper surface of the base 1 is provided with a through hole 2, and a two-way threaded rod 3 is arranged in the through hole 2, Both ends of the two-way threaded rod 3 are rotatably connected to both sides of the inner wall of the through hole 2 through bearings 4. The outer surface of the two-way threaded rod 3 is threadedly connected with two threaded caps 5, and the upper surface of the threaded cap 5 is connected to the push assembly 6. The lower surface is fixedly connected, the left side of the pushing assembly 6 is fixedly connected to one side of the air guiding plate 7 , and the top side of the air guiding plate 7 communicates with the upper surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com