A fixing device for transformer copper bars

A technology for fixing devices and transformers, which is applied in transformer/inductor components, transformer/inductor cooling, inductor/transformer/magnet manufacturing, etc., which can solve the problem of temperature rise, high temperature of copper bars, and lack of buffering of copper bars at the beginning Function and other issues, to achieve the effect of improving the stability of the connection and easy distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

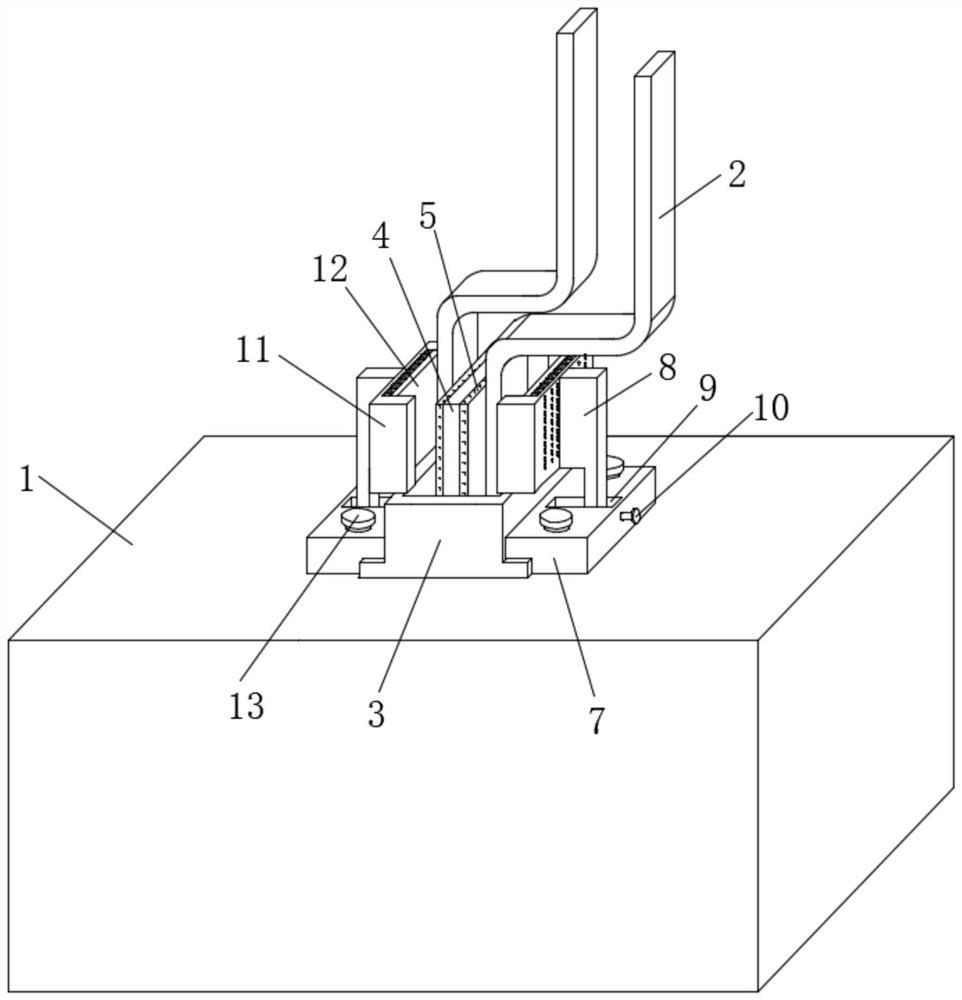

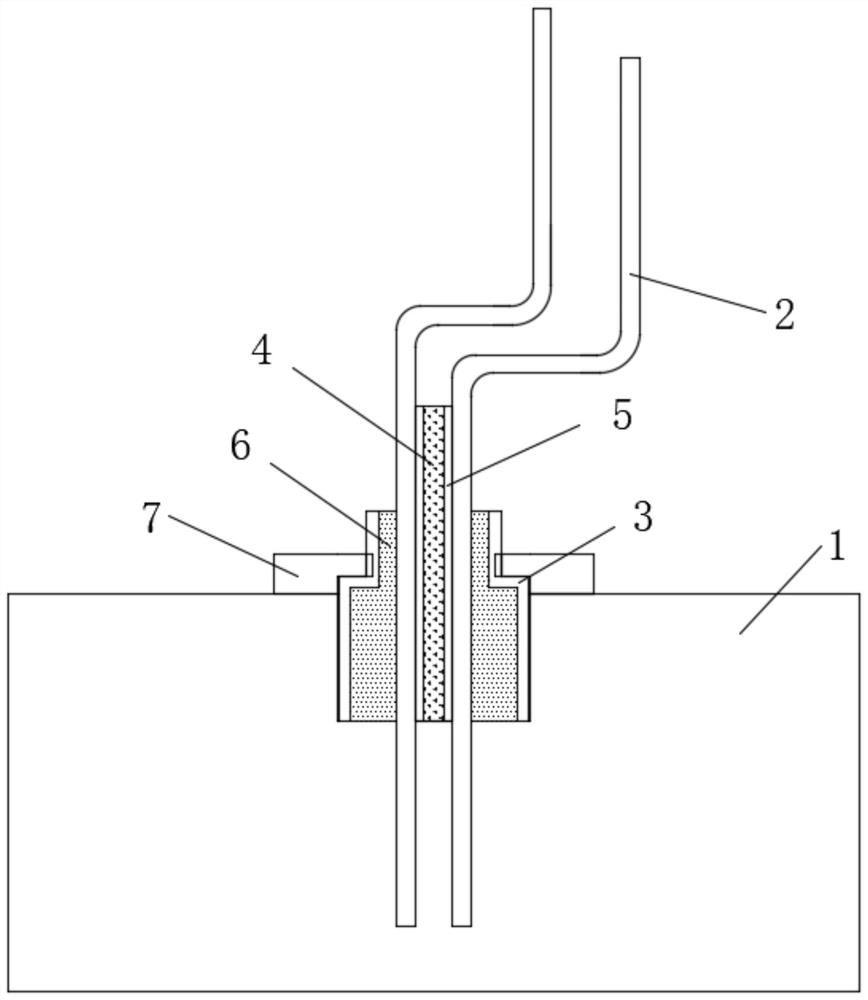

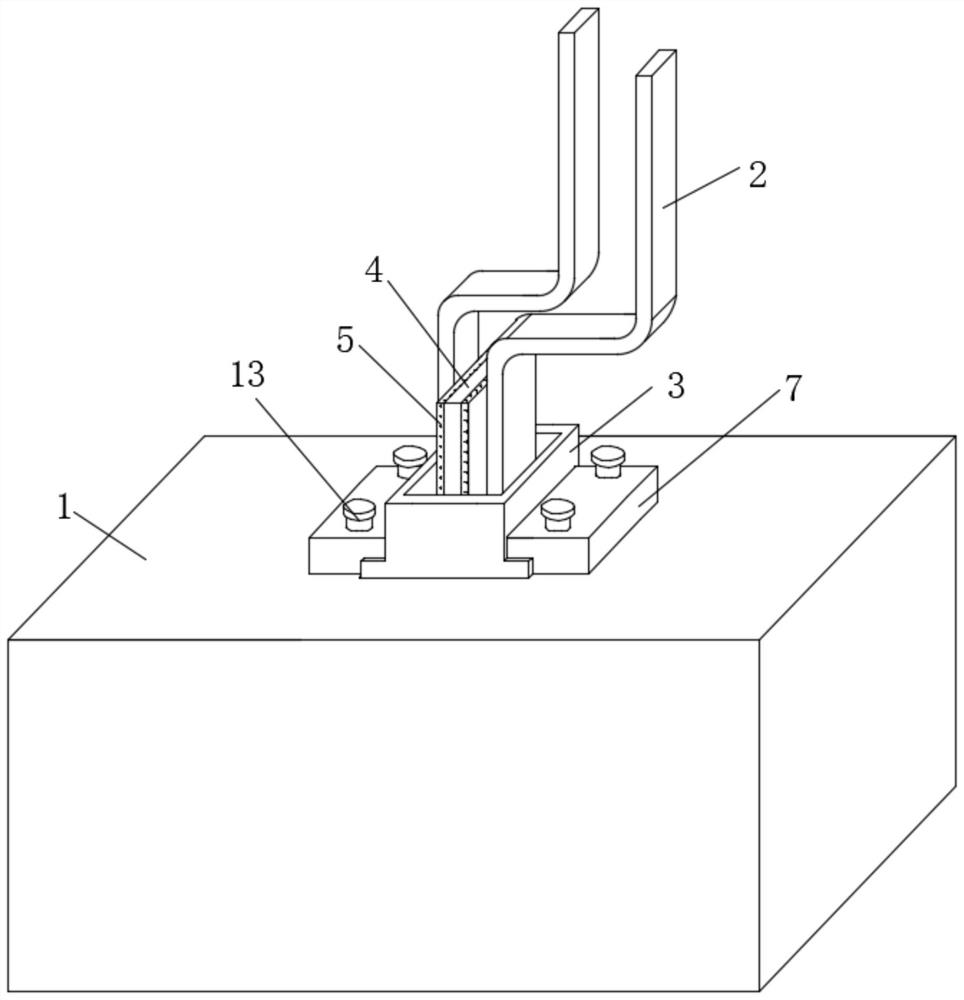

[0041] see Figure 1-Figure 2 , a fixing device for a copper bar of a transformer, including a convex mounting plate 3 for fixing two copper bar bodies 2 to an outgoing line template 1, the convex mounting plate 3 is embedded in the outgoing line template 1, and the convex mounting plate 3 is embedded in the outgoing line template 1. The interior of the mounting plate 3 is provided with a fixed cavity for fixing the copper bar body 2. The middle part of the fixed cavity is fixedly connected with an insulating partition 4, and the two copper bar bodies 2 are located on both sides of the insulating partition 4. Both sides of the plate 4 are provided with a buffer layer 5 against the inner side walls of the two copper bar bodies 2, and the cooperation of the insulating partition 4 and the convex mounting plate 3 can not only realize the limit and fixation of the two copper bar bodies 1 It also plays an insulating role between the two copper bar bodies, while the buffer layer 5 pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com