Small square hole electric drill

An electric drill, a small technology, applied in the direction of drilling/drilling equipment, portable drilling rigs, portable mobile devices, etc., can solve the problems of square hole drill bit drilling breakage, strong output power, etc., and achieve the effect that the position is not easy to shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

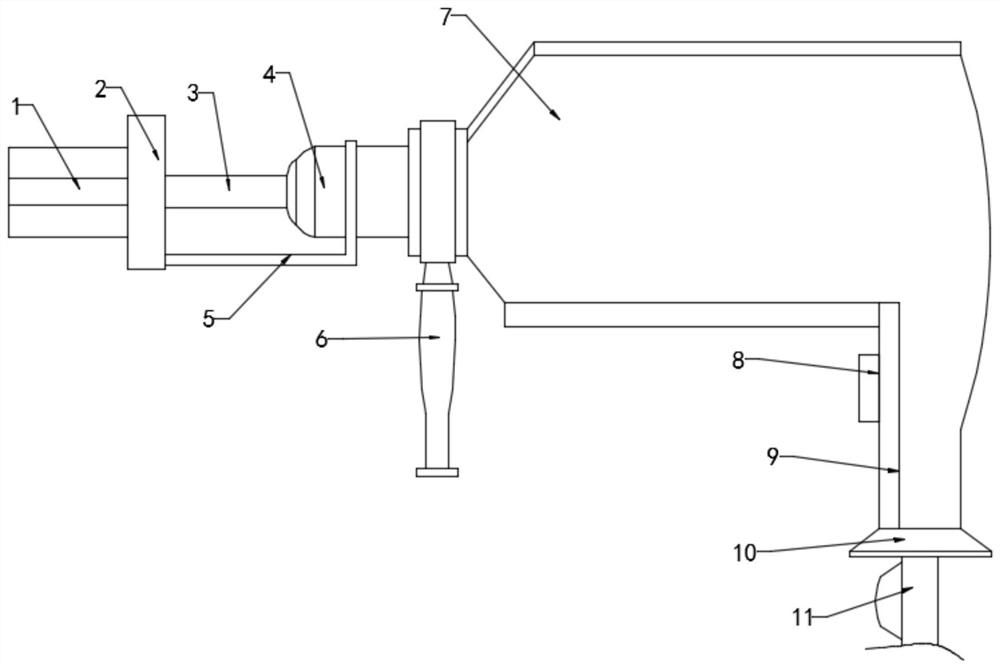

[0028] see figure 1 , a small square hole electric drill is provided in Embodiment 1 of the present invention, and the small square hole electric drill includes:

[0029] The electric drill body 7, the front end of the electric drill body 7 is provided with a terminal 4, the front end of the terminal 4 is equipped with a drilling assembly for drilling a square hole, the electric drill body 7 is provided with a driving assembly, and the driving assembly drives the drilling assembly to run, and then the workpiece to be processed Drill square holes.

[0030] In one embodiment of the present invention, in order to improve the comfort when using the small square hole electric drill, a handle is installed on the electric drill body 7, and the number of handles is two, which are the first handle 6 and the first handle respectively. The second turning handle 9, the first handle 6 and the second turning handle 9 are distributed on the left and right sides of the lower end of the elect...

Embodiment 2

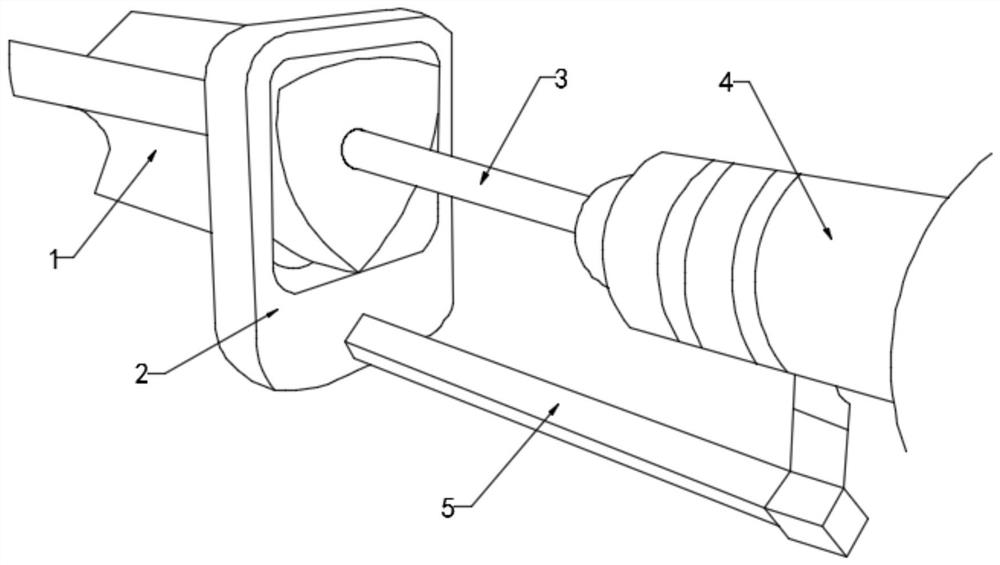

[0033] see figure 1 and image 3 , the drilling assembly provided in Embodiment 2 of the present invention, the drilling assembly includes:

[0034] A square hole drill bit 1, the square hole drill bit 1 is in the shape of a triangular prism, the square hole drill bit 1 is connected to the output shaft 3, the output shaft 3 extends into the interior of the terminal 4, and the output shaft 3 is connected to the drive assembly inside the terminal 4;

[0035] Limiting frame 2, there is a slot in the middle of the limiting frame 2, the limit movement at the connection between the square hole drill bit 1 and the output shaft 3 is inside the slot opened in the middle of the limiting frame 2, and one end of the limiting frame 2 passes through the bracket 5 It is connected with the terminal 4, and one end of the bracket 5 is welded and fixed on the terminal 4;

[0036] The drive assembly drives the output shaft 3 to rotate, and the running output shaft 3 drives the square hole drill...

Embodiment 3

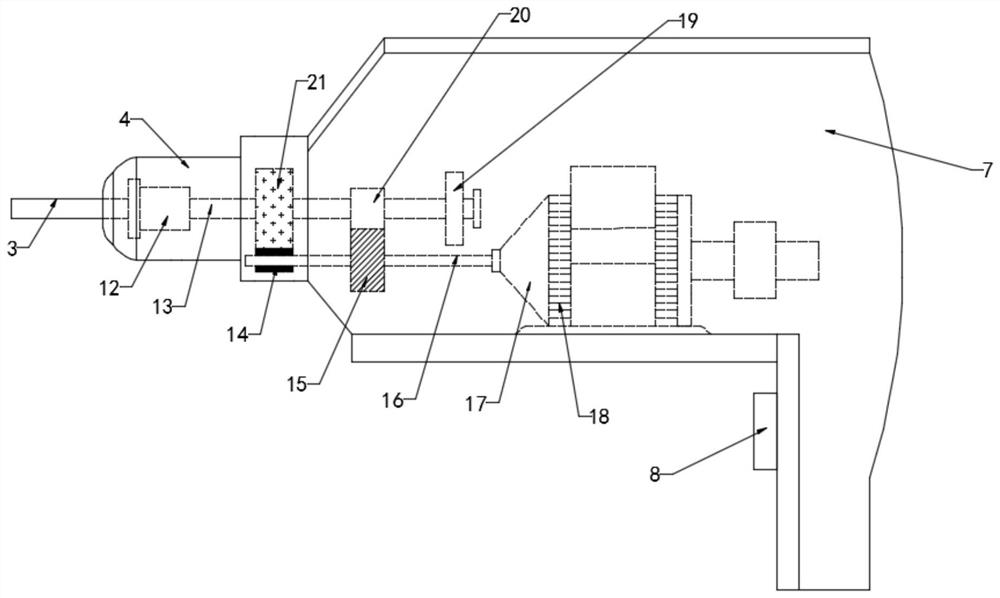

[0039] see figure 2 , the drive assembly provided in Embodiment 3 of the present invention, the drive assembly includes:

[0040] A motor 17, the motor 17 is used for output power, the power output direction of the motor 17 is equipped with a second rotating shaft 16, and the second rotating shaft 16 is respectively provided with a first transmission gear 14 and a second transmission gear 15;

[0041] The first rotating shaft 13, one end of the first rotating shaft 13 is connected with the output shaft 3 inside the terminal 4, the other end of the first rotating shaft 13 extends into the inside of the electric drill body 7 and is fixed by a shaft seal 19. The first rotating shaft 13 is equipped with a second Four transmission teeth 21 and the third transmission tooth 20; the fourth transmission tooth 21 and the first transmission tooth 14 are engaged with each other, and the third transmission tooth 20 and the second transmission tooth 15 are engaged with each other;

[0042...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com