A New Type Supporting Insulator Turning Fixture

A technology for supporting insulators and turning, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of complex fixture structure, high production cost, low product qualification rate, etc. Strong, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

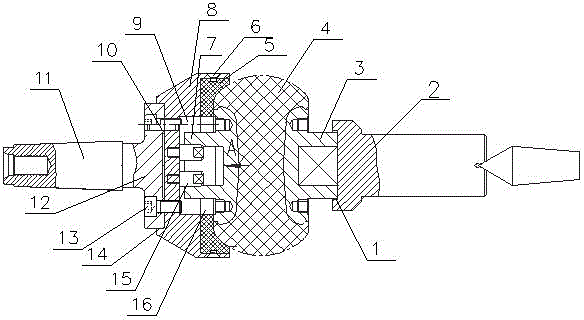

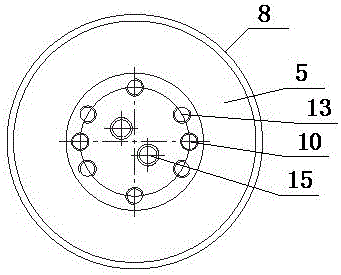

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0012] As shown in the figure, it includes a top seat 2, a fixed seat 12 and a sleeve 8. The sleeve 8 is an integrally formed structure. The left end of the sleeve 8 is provided with a fixed seat cavity 14, and the right end is provided with a The workpiece concave cavity 9, the right end of the fixed seat 12 is located in the fixed seat concave cavity 14 of the sleeve seat 8, this structure strengthens the fixed firmness of the fixed seat 12 and the sleeve seat 8, and prevents displacement; The left part of the fixed seat 12 is a Morse taper shank 11, which can be matched with a standard taper sleeve by using a standard Morse taper shank, and is applied to various machine tools with a wide range of processing; the workpiece cavity 9 is provided with a pull pin 15, and the left end of the pull pin 15 is fixed on the sleeve 8, the right end of the sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com