Method for soldering interconnectors to photovoltaic cells

A solar cell and soldering technology, which is applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of high cost of solar cells, no disclosure of solutions, rupture of solar cells, etc., so as to reduce the compression of bonding wires. The effect of strength, not easy to position deviation, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0054] The first embodiment of the cooling mechanism after the solder has been melted will be described.

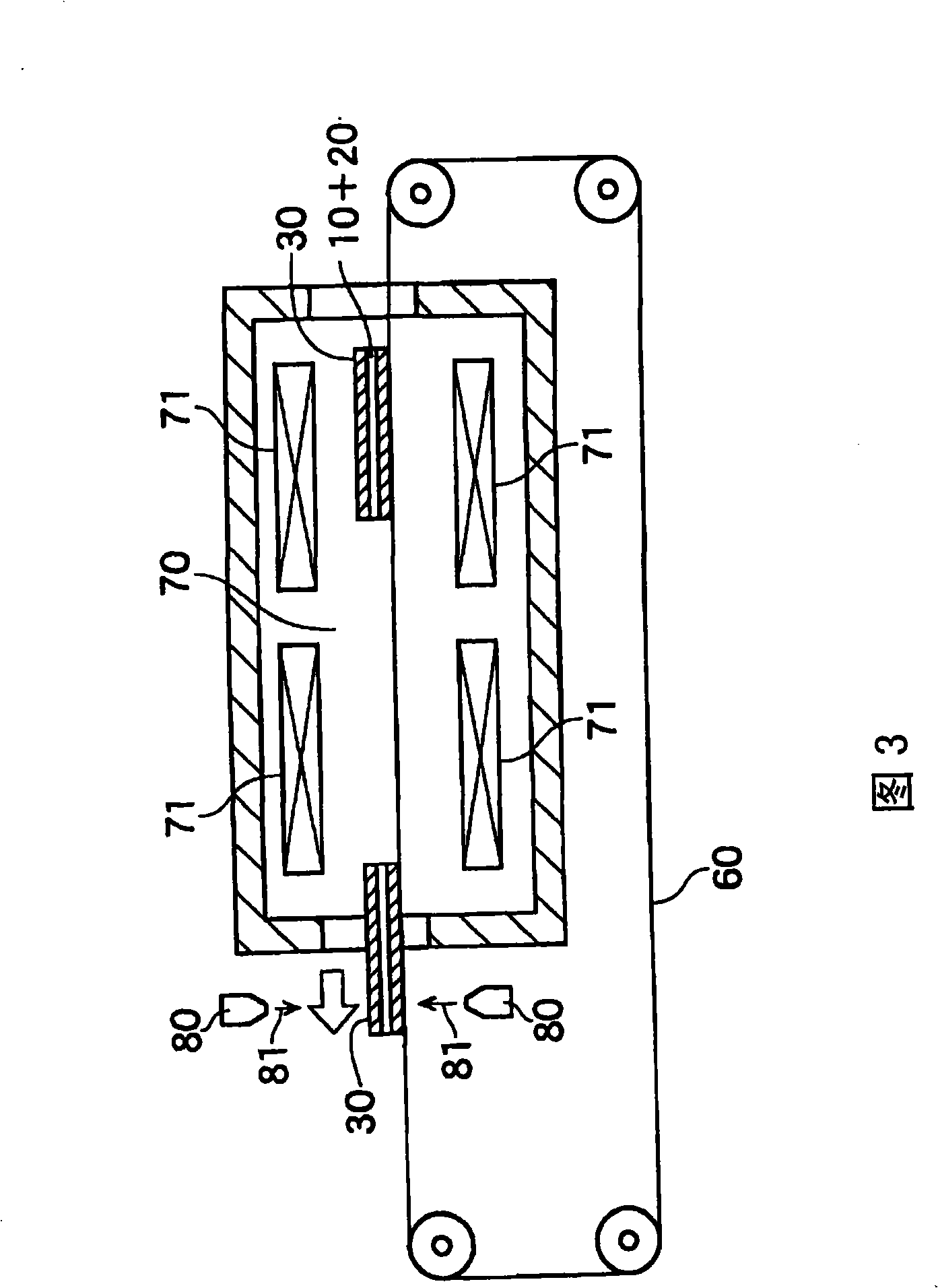

[0055] The cooling mechanism 80 provided above and below the outlet of the heating space 70 cools the solar cells 10 on the transport holder 30 sent from the heating space 70 by the conveyor belt 60 of FIG. 3, and the molten solder of the bonding wire 20 22 starts curing from the end of the solar cell unit 10. In this way, the conveyance holder 30 is conveyed by the conveyer belt 60, and the solar battery cells 10 are sequentially cooled from the end by the cooling mechanism 80. In addition, in this embodiment, cold air 81 is used as the cooling mechanism 80. As shown in FIG. 3, the cold air 81 is blown from a blowing outlet such as a nozzle attached to the outlet of the heating space 70. In this case, not only the cold air 81 is blown from above, but also the cold air 81 is blown from the lower side.

[0056] The blowing outlet 82 provided above and below the outlet of the h...

Embodiment approach 2

[0058] The second embodiment of the cooling mechanism after the solder has been melted will be described. In this embodiment, the air outlet 82 provided above and below the outlet of the heating space 70 is as Figure 6 As shown, the front end thereof traverses the entire width of the solar cell unit 10 and is formed into a shape that shrinks toward the bonding wire 20.

Embodiment approach 3

[0060] The third embodiment of the cooling mechanism after the solder has been melted will be described. In this embodiment, due to the temperature distribution of the unit 10, etc., the air outlet at the front end is as Figure 7 As shown, it is formed into a plurality of blowout ports, and each blowout port is provided with a regulating valve 83 to adjust the flow rate of the cold air.

[0061] use Figure 8 Describes how to use such a cooling mechanism 80 to solidify the bonding wire 20 on the solar cell unit 10.

[0062] Figure 8 Is a cross-sectional view of the bonding wire 20 during cooling, Figure 8 (a) is the case where the cooling is gradually carried out in a normal atmosphere, Figure 8 (b) is the case where the cooling mechanism 80 is used to perform cooling sequentially from the end of the unit.

[0063] in Figure 8 In (a), since the cooling is gradually performed, the cooling of the bonding wire 20 proceeds from the both ends of the unit to the center. In addition, du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com