Connecting structure of concrete precast beam and steel beam and construction method of connecting structure

A technology for connecting structures and construction methods, which is applied in the direction of truss structures, joists, girders, etc., can solve the problems of high construction/assembly precision requirements, inconvenient construction, and structural reliability to be improved, and achieve low construction precision requirements, Easy operation and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

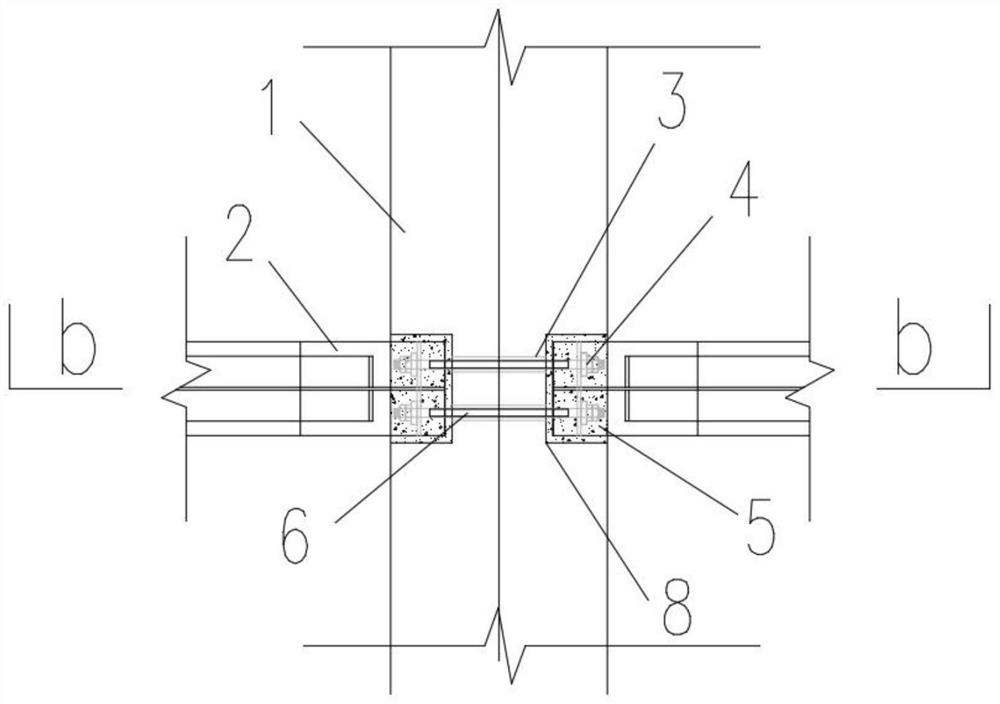

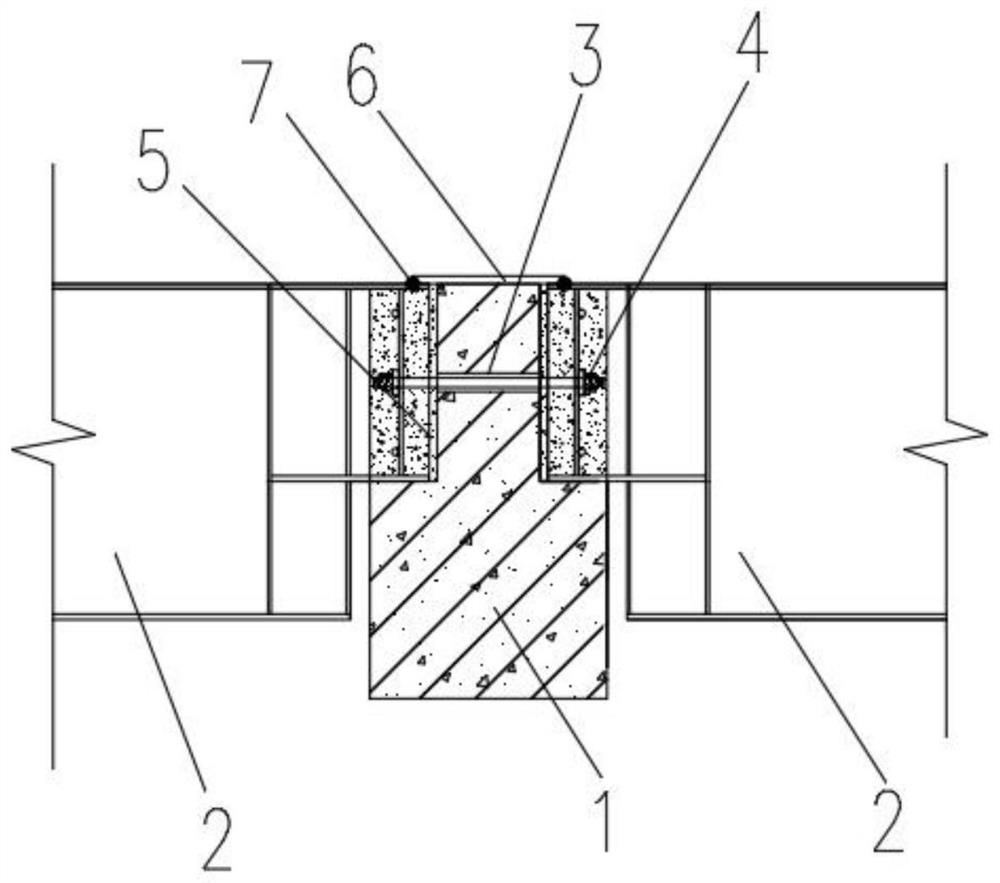

[0042] A connection structure of a prefabricated concrete beam and a steel beam, such as Figures 1 to 2 As shown, including concrete precast beam 1 (prestressed concrete precast beam) and steel beam 2 (H-shaped steel beam);

[0043] The prefabricated concrete beam 1 is prefabricated in the factory according to the design drawing. The prefabricated concrete beam 1 is reserved with two grooves 8 matching the ends of the steel beam 2. The two grooves 8 are symmetrically arranged on two sides of the prefabricated concrete beam 1. Side and the two grooves 8 are coaxial, the coaxial axes of the two grooves 8 are perpendicular to the length direction of the concrete prefabricated beam 1, and two bolt holes 3 for the pull bolts 4 to pass through are reserved between the two grooves 8. ;

[0044] The ends of the two steel beams 2 are arranged in the two grooves 8 of the prefabricated concrete beam 1, and the two steel beams 2 are fixed after the tension bolts 4 pass through the bolt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com