Coal mine electromechanical equipment for coal mining

A technology for electromechanical equipment and coal mines, applied in the field of electromechanical equipment in coal mines, can solve the problems of easy shaking or tilting, affecting the health of workers, reducing the practicability of the device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

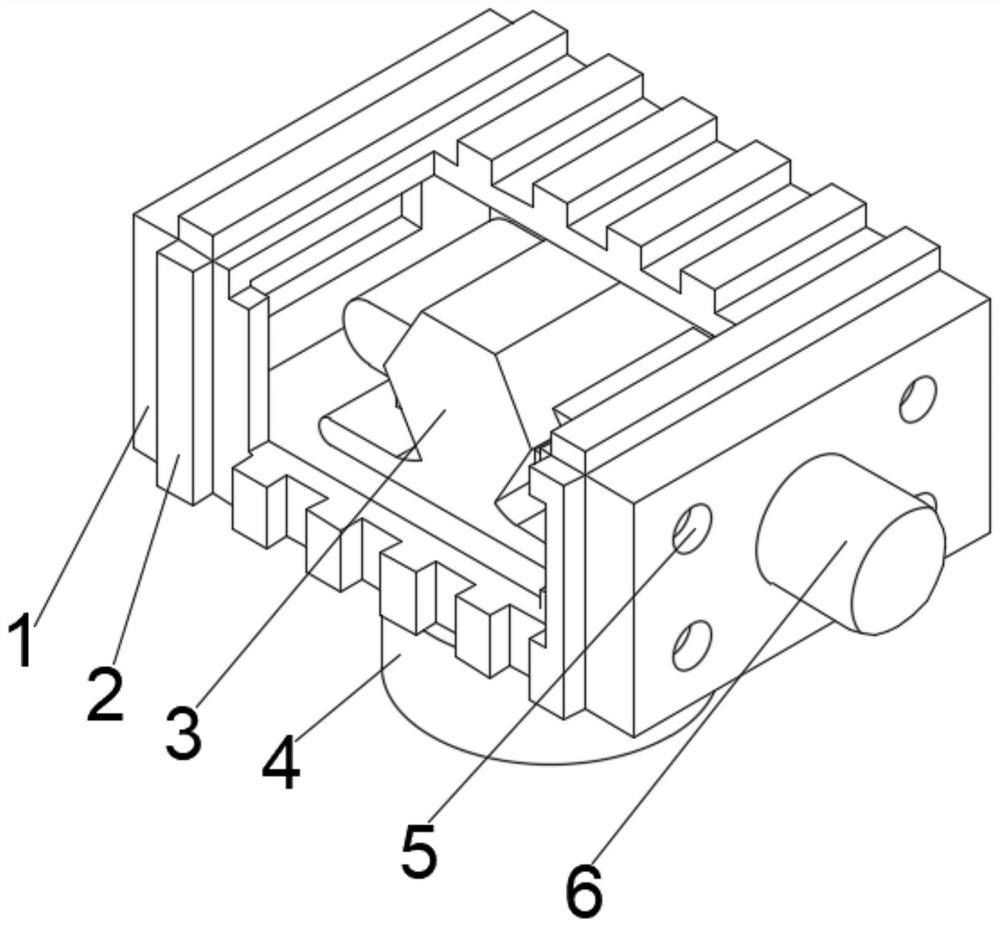

[0033] see Figure 1-2 , the present invention provides a technical solution: a coal mine electromechanical equipment for coal mining, including a main body 1, a base 4 is fixedly connected to the middle of the bottom of the main body 1, and the top end of the base 4 runs through the main body 1 and extends to the main body 1 Inside, the top of the main body 1 is fixedly connected with a dust-proof net 2, and the middle part of the right outer wall of the main body 1 is provided with a motor 6. The middle position of the bottom is fixedly connected with the working device 3 .

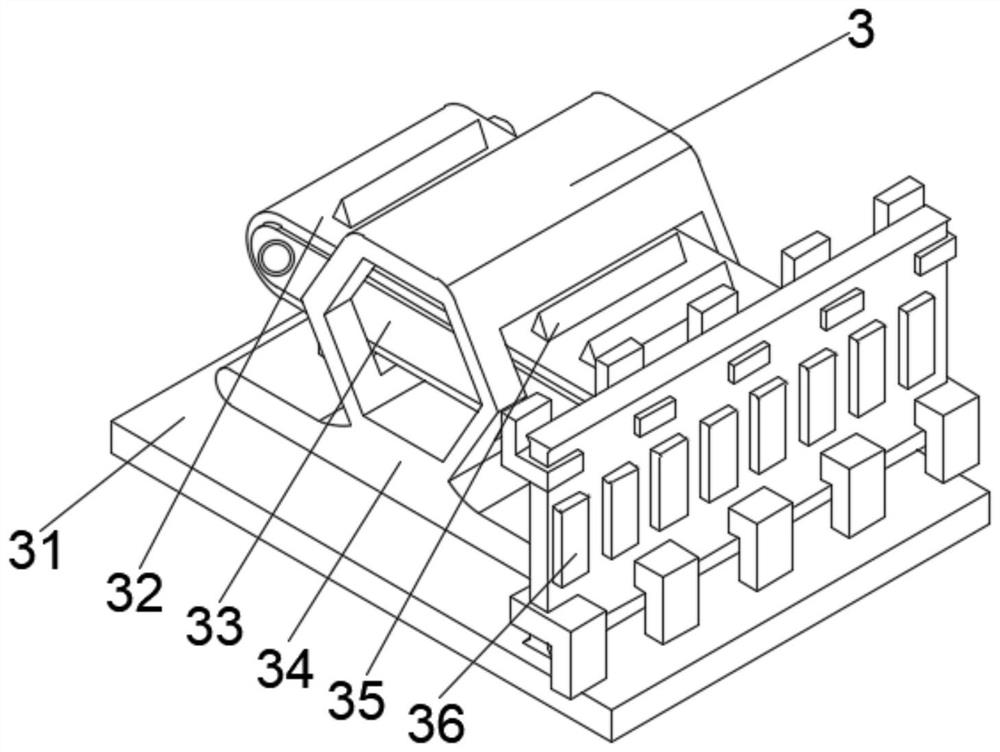

[0034] Wherein, working device 3 comprises base plate 31, and the top left side of base plate 31 is fixedly connected with cleaning mechanism 34, and the bottom of both sides outer wall of cleaning mechanism 34 is provided with organic frame 33, and the both sides outer walls of frame 33 are all provided with conveyor belt 32, and conveyor belt 32 is fixedly connected with a blocking plate 35 on the si...

Embodiment 2

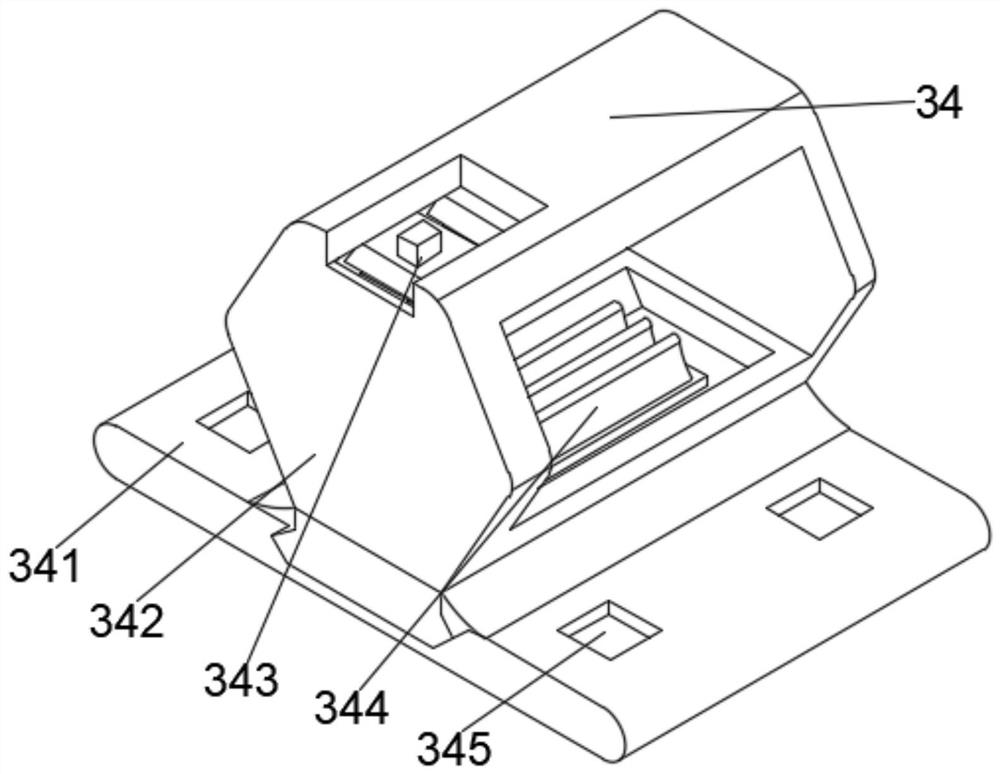

[0037] see Figure 1-4 , on the basis of Embodiment 1, the present invention provides a kind of technical scheme: the component one of cleaning mechanism 34 comprises bottom set plate 341, and the top middle position of bottom set plate 341 is fixedly connected with fixed box 342, and the inner cavity of fixed box 342 The bottom is fixedly connected with a scraper plate 344, the top of the inner cavity of the fixed box 342 is fixedly connected with a contactor 343, the top of the contactor 343 runs through the fixed box 341, and the top of the bottom plate 341 is located on both sides of the fixed box 342 to open a fixed groove 345.

[0038] Wherein, the first component of the filter mechanism 36 includes a separator 362, the two ends of the separator 362 are fixedly connected with a fixed block 364, and a lower frame 361 is arranged between the bottom of the separator 362 and the fixed block 364, and the top of the lower frame 361 The left side passes through the separator 3...

Embodiment 3

[0041] see Figure 1-6 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: component 2 of the cleaning mechanism 36 includes an auxiliary plate d1, the top of the auxiliary plate d1 is fixedly connected with a guide box d2, and the inner cavity of the guide box d2 The top is provided with an extruding block d5, the top of the extruding block d5 runs through the guide box d2 and extends to the outside of the guide box d2, the middle position of the inner cavity bottom of the guide box d2 is provided with a moving frame d4, and the inner cavity bottom of the guide box d2 is located at Transition blocks d3 are fixedly connected to both sides of the mobile frame d4.

[0042] Among them, the second component of the transition mechanism 36 includes a protective column t2, the bottom of the protective column t2 is fixedly connected with the limit block t1, the top of the protective column t2 is fixedly connected with the installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com