Blade and shaft connecting structure convenient for dismounting and manufacturing method thereof

A shaft connection and blade technology, applied in grain processing, etc., can solve problems such as abnormal vibration and noise, high maintenance cost, thermal deformation of the shaft, etc., and achieve the effects of reducing vibration, easy maintenance and replacement, and easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

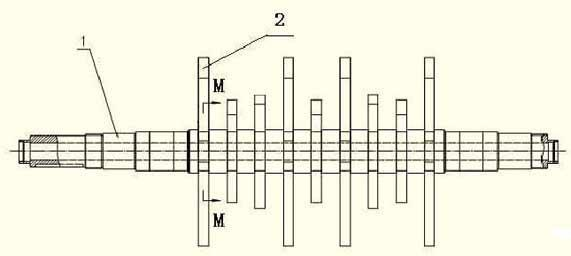

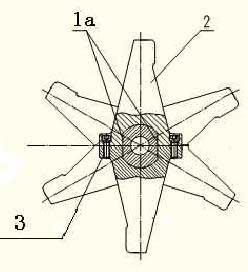

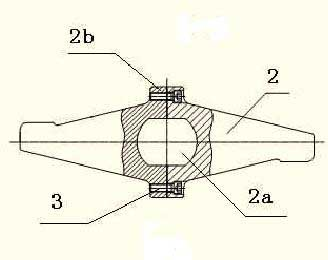

[0018] Such as figure 2 , image 3 As shown, the present invention includes a shaft 1 and a blade 2 mounted on the shaft, and each blade is made into two halves that are clamped on the shaft and connected with the shaft, and a semicircle that fits with the shaft is processed in the middle of the bottom end of each half blade Bottom notch 2a, lugs 2b with mounting holes processed on both sides of the bottom end of the blade, a bayonet is processed on the shaft 1 on which the blade is installed, and the two halves of the blade are spliced and snapped into the bayonet of the shaft and connected to each other through the connecting screw 3 coupling.

[0019] The method of making a blade-shaft connection structure that is easy to disassemble is as follows:

[0020] After machining the shaft 1, mill out the bayonet for installing the blade 2, and finish machining each bayonet surface 1a to the required size, and the bayonet width tolerance is H9;

[0021] ② if Figure 4 Mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com