Highway and railway layered steel box beam

A steel box girder and box girder technology, applied in bridges, buildings, etc., can solve the problems of long and slender bolt holes and rods, high construction accuracy requirements, and inability to save steel for side spans, and achieves an increase in the operating wind speed threshold. , The effect of improving the utilization rate of materials and eliminating the amount of steel used for side spans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

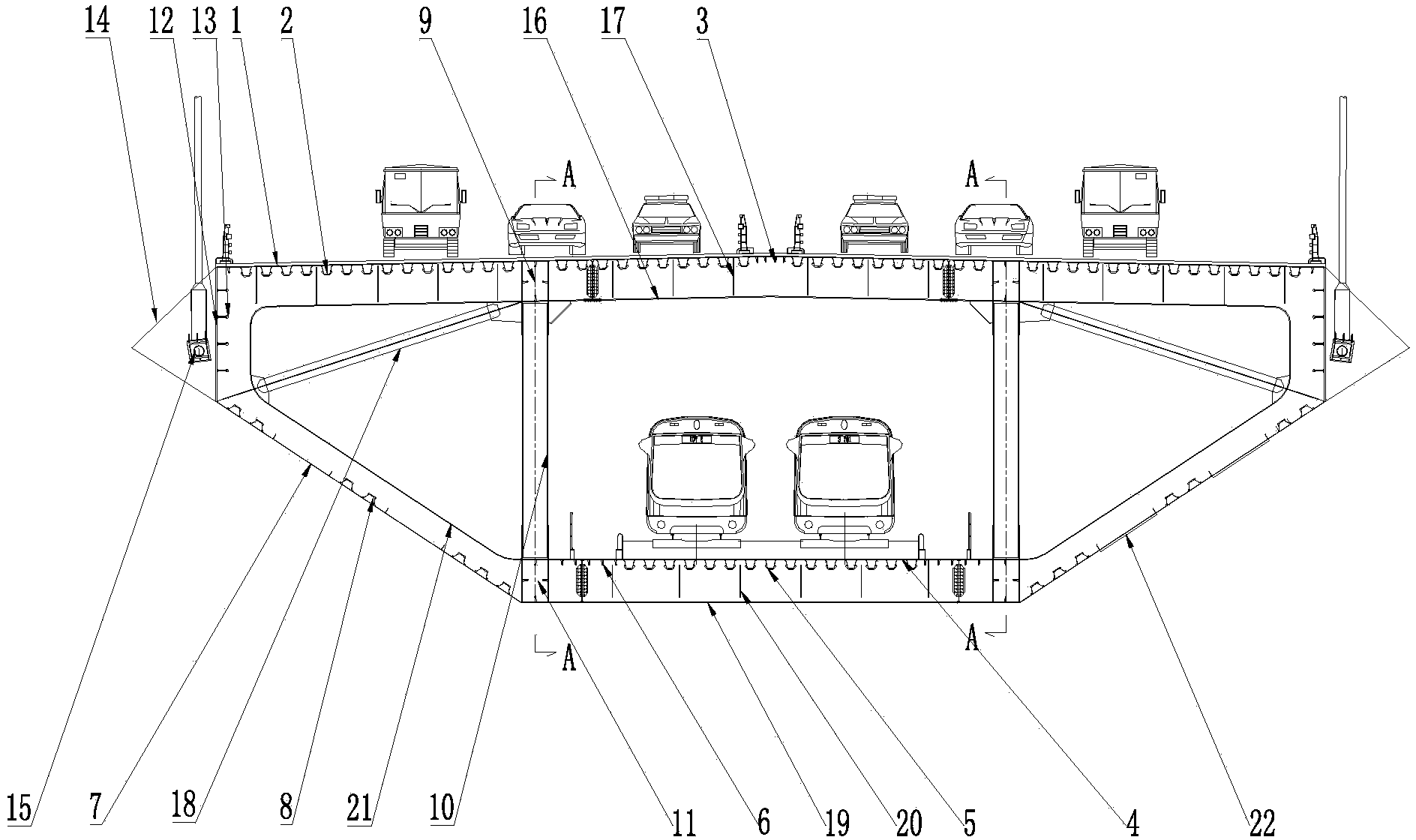

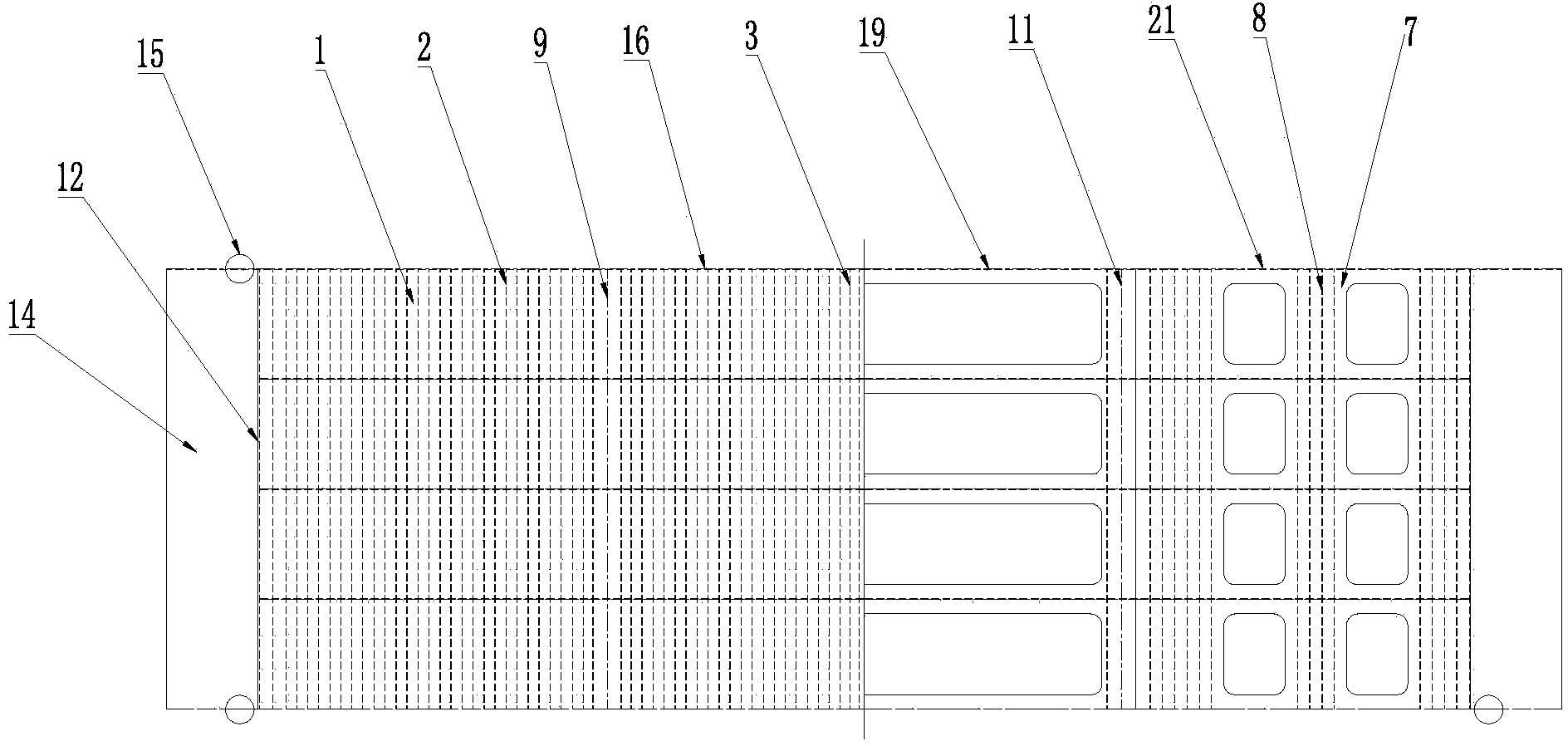

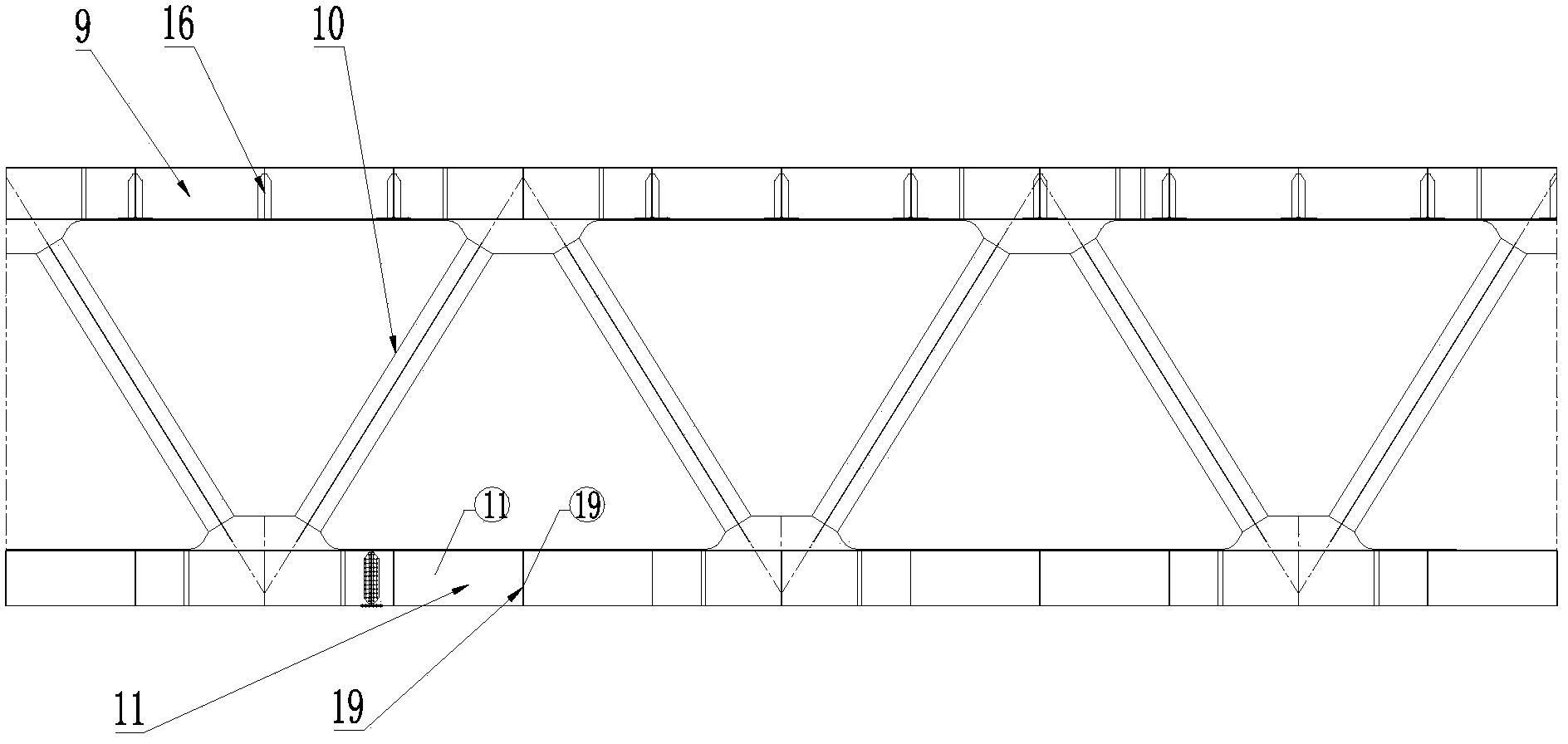

[0030] As shown in the figure, a public-iron layered steel box girder includes a box girder top plate 1 and a box girder bottom plate 4, the box girder bottom plate 4 is located below the middle of the box girder top plate 1, and the box girder top plate 1 is used to arrange roads. The box girder bottom plate 4 is used for arranging the railway; a support structure is provided between the box girder top plate 1 and the box girder bottom plate 4, the support structure includes a top plate beam 16 and a bottom plate beam 19, and the top plate beam 16 is arranged on the lower end surface of the box girder top plate 1 and Horizontally arranged, the bottom beam 19 is arranged on the lower end surface of the box girder floor 4 and arranged horizontally. The two ends of the top beam 16 are longitudinally provided with a truss-type mid-web cho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com